NTC temperature sensor suitable for concrete temperature monitoring, preparation method and application

A technology of temperature sensor and concrete temperature, applied in the direction of thermometers, thermometers, instruments, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve the problems of no NTC temperature sensor and preparation method, and few NTC temperature sensors, etc., to achieve effective Conducive to precise monitoring and effective control, wide temperature measurement range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

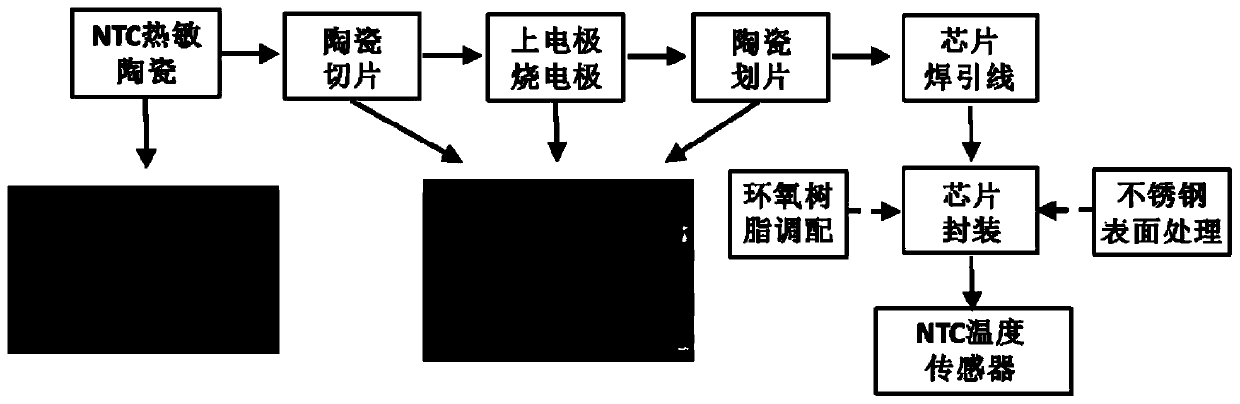

Method used

Image

Examples

Embodiment 1

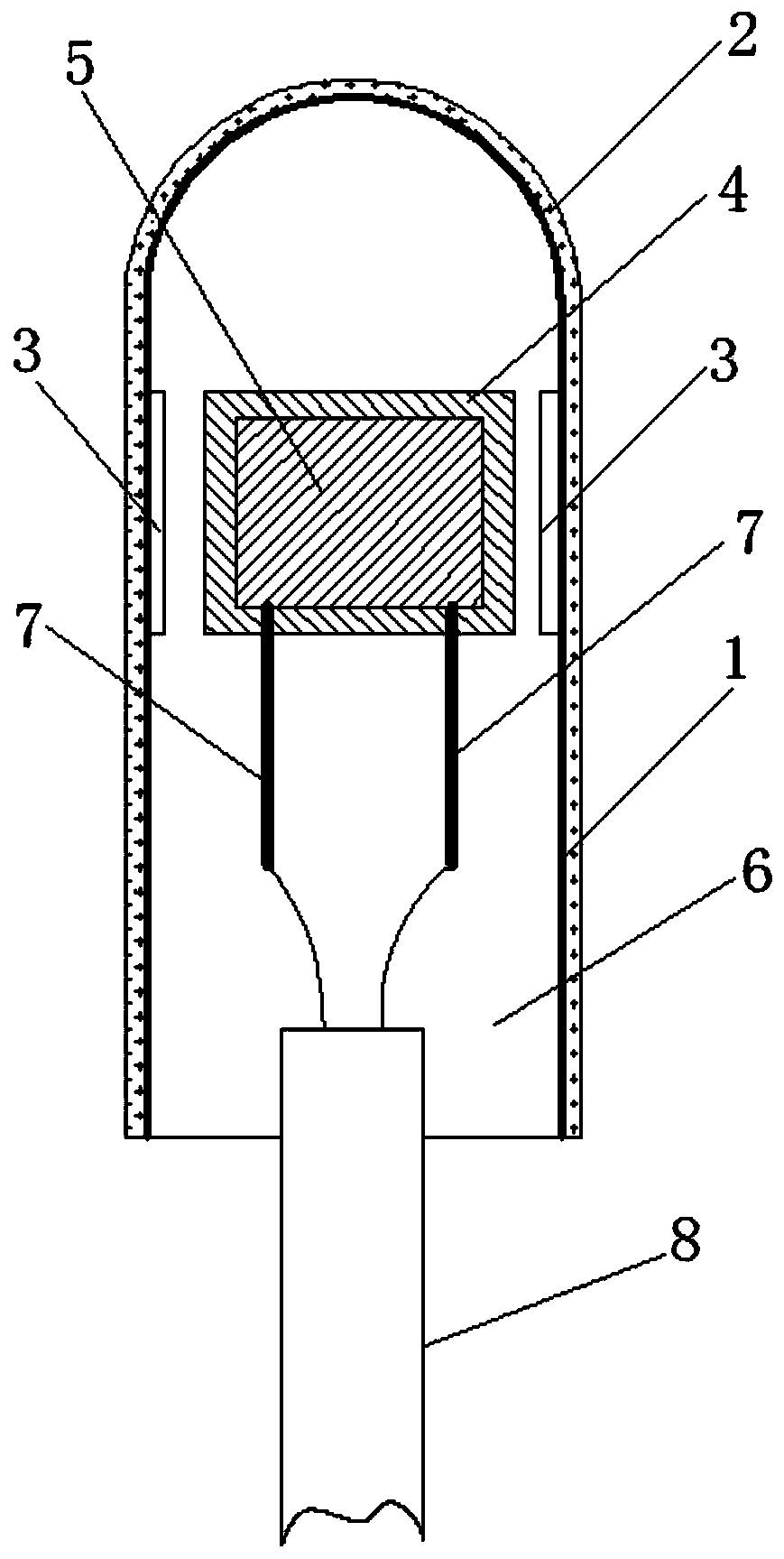

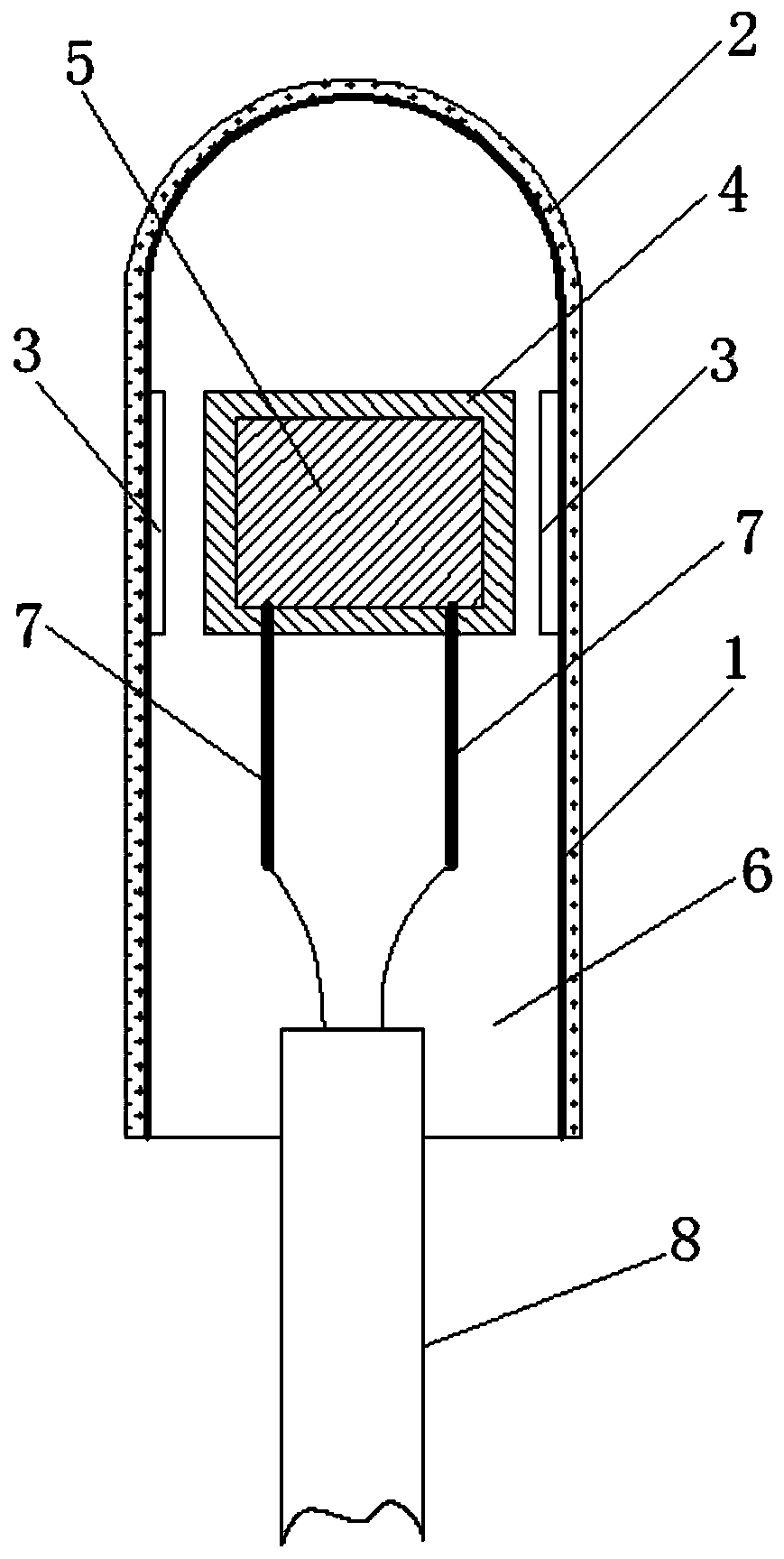

[0058] An NTC temperature sensor suitable for concrete temperature monitoring, refer to the attachment figure 1 , Which includes a body and a wire; the body includes: a stainless steel housing 2 and an NTC thermal ceramic chip 5 encapsulated inside the inner housing; one end of the stainless steel housing 2 is closed, the other end is open, and the stainless steel housing 2 The outer surface is coated with nano-TiO 2 Coating 1; the outer surface of the NTC thermal ceramic chip 5 is provided with a silver electrode layer, and the outer surface of the silver electrode layer is covered with an encapsulation layer 4; one end of the wire 8 is arranged on the NTC thermal ceramic chip 5 The other end of the wire 8 extends from the open end port of the stainless steel housing 2 to the outside of the stainless steel housing; the inner surface of the stainless steel housing is provided with a thermally conductive silicone grease sealing layer 3, and the thermally conductive silicone grease...

Embodiment 2

[0060] An NTC temperature sensor suitable for monitoring the temperature of concrete. It is the same as Embodiment 1, except that the material of the encapsulation is epoxy resin or fiber reinforced resin bar. The encapsulation layer is a glass seal protection layer. The encapsulation layer can not only provide the first protective layer for NTC thermal ceramic chips; it can also reduce the impact of subsequent packaging processes on the chips and leads. The wire is a three-core sensor cable; the material of the stainless steel shell is SUS304.

Embodiment 3

[0062] An NTC temperature sensor suitable for concrete temperature monitoring. Same as Example 1, except that the main performance parameters of the NTC thermal ceramic material are: R 25℃ =(10~20kΩ)±2.5%; B 25 / 85 =(3900~4200K)±2.0%); NTC thermal ceramic materials with this performance parameter can better match the temperature variation range of concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com