Recovery method for SCR waste flue gas denitration catalyst

A technology of denitrification catalyst and recovery method, which is applied in the field of recovery of SCR waste gas denitrification catalyst, can solve the problems that the comprehensive recovery of waste SCR flue gas denitrification catalyst cannot be applied, achieve good economic and environmental benefits, low cost, and improve the environment The effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

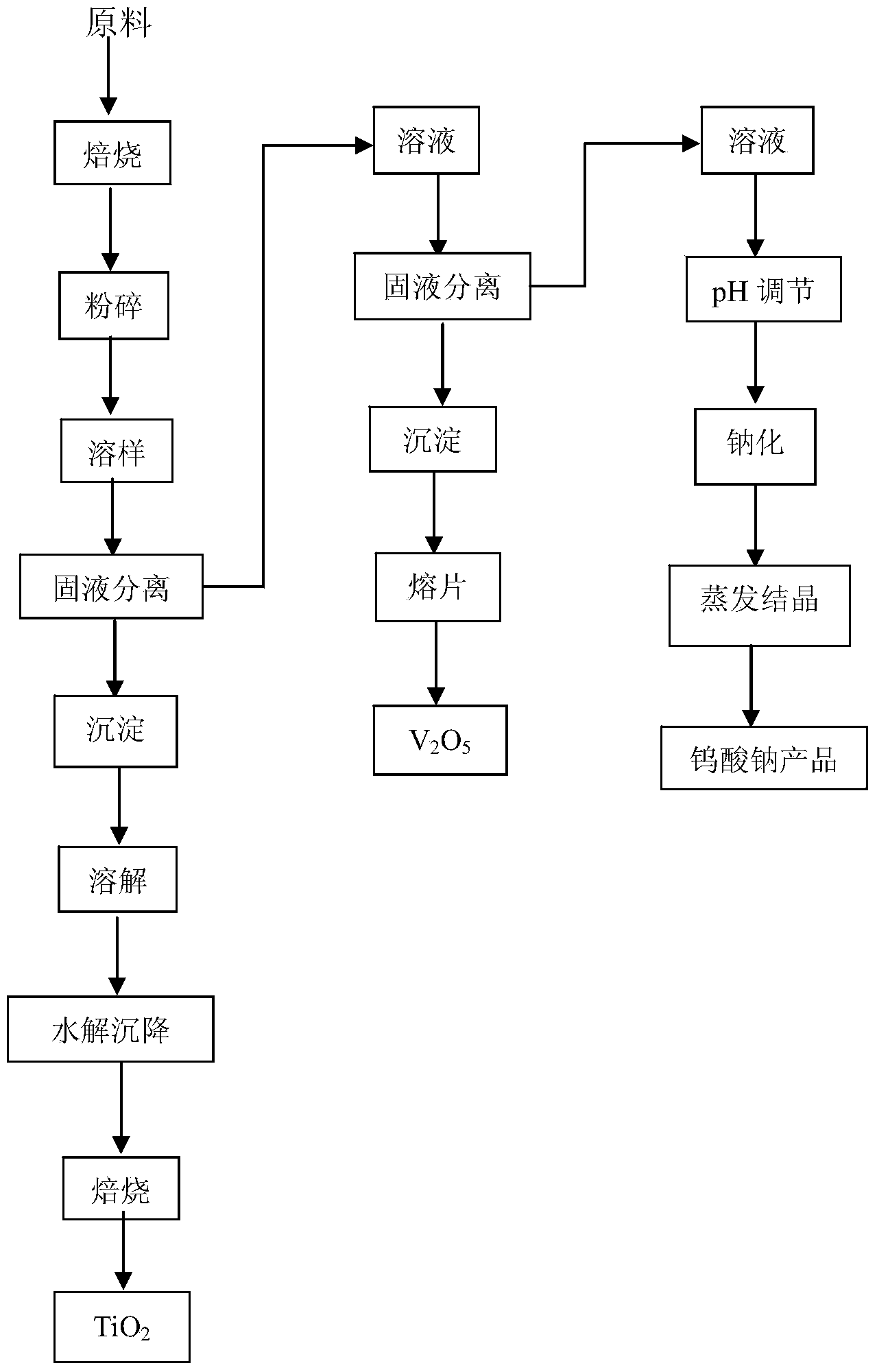

[0052] Example 1: Such as figure 1 Shown: the method for recovering metal oxides from the flue gas denitrification catalyst in this embodiment adopts the process of hydrometallurgy and proceeds according to the following steps.

[0053] Pre-roasting of raw materials: Take the expired honeycomb waste flue gas denitrification catalyst and put it into the rotary. Carry out high-temperature roasting at 650°C to remove Hg, As and organic impurities that may be adsorbed on the surface, and keep the temperature for 4 hours.

[0054] Pulverization: Put the waste flue gas denitrification catalyst after high-temperature roasting into a crusher, and pulverize it to a particle size of ≤ 200 μm to obtain a uniform powder.

[0055] Hot water leaching: After the agglomerates roasted at high temperature are pulverized by a pulverizer, they are leached with hot water at 80~90°C under sufficient stirring to dissolve part of the solids in water. The water consumption is a liquid-solid weight...

Embodiment 2

[0061] Example 2: Such as figure 1 Shown: the method for recovering metal oxides from the flue gas denitrification catalyst in this embodiment adopts the process of hydrometallurgy and proceeds according to the following steps.

[0062]Pre-roasting of raw materials: Take the expired honeycomb waste flue gas denitrification catalyst and put it into the rotary machine, perform high-temperature roasting at 680°C to remove Hg, As and organic impurities that may be adsorbed on the surface, and keep the temperature constant for 3.5 hours.

[0063] Pulverization: Put the waste flue gas denitrification catalyst after high-temperature roasting into a crusher, and pulverize it to a particle size of ≤ 200 μm to obtain a uniform powder.

[0064] Hot water leaching: After the agglomerates roasted at high temperature are pulverized by a pulverizer, they are leached with hot water at 80~90°C under sufficient stirring to dissolve part of the solids in water. The water consumption is a liq...

Embodiment 3

[0069] Example 3: Such as figure 1 Shown: the method for recovering metal oxides from the flue gas denitrification catalyst in this embodiment adopts the process of hydrometallurgy and proceeds according to the following steps.

[0070] Pre-roasting of raw materials: Take the expired honeycomb waste flue gas denitrification catalyst and put it into the rotary machine, and perform high-temperature roasting at 700°C to remove Hg, As and organic impurities that may be adsorbed on the surface, and keep the temperature for 3 hours.

[0071] Pulverization: Put the waste flue gas denitrification catalyst after high-temperature roasting into a crusher, and pulverize it to a particle size of ≤ 200 μm to obtain a uniform powder.

[0072] Hot water leaching: After the agglomerates roasted at high temperature are pulverized by a pulverizer, they are leached with hot water at 80~90°C under sufficient stirring to dissolve part of the solids in water. The water consumption is a liquid-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com