Process for controlling smelting silicon content of low-silicon steel

A technology of silicon content and low silicon steel is applied in the low silicon steel smelting silicon content control process, the low silicon variety steel prevents silicon increase in the smelting process and stably controls the silicon content of the molten steel end point, and can solve the problem of poor slag blocking in tapping and casting blanks. , change the judgment and other issues, to achieve the effect of improving the hit rate of the end component, improving economic benefits and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

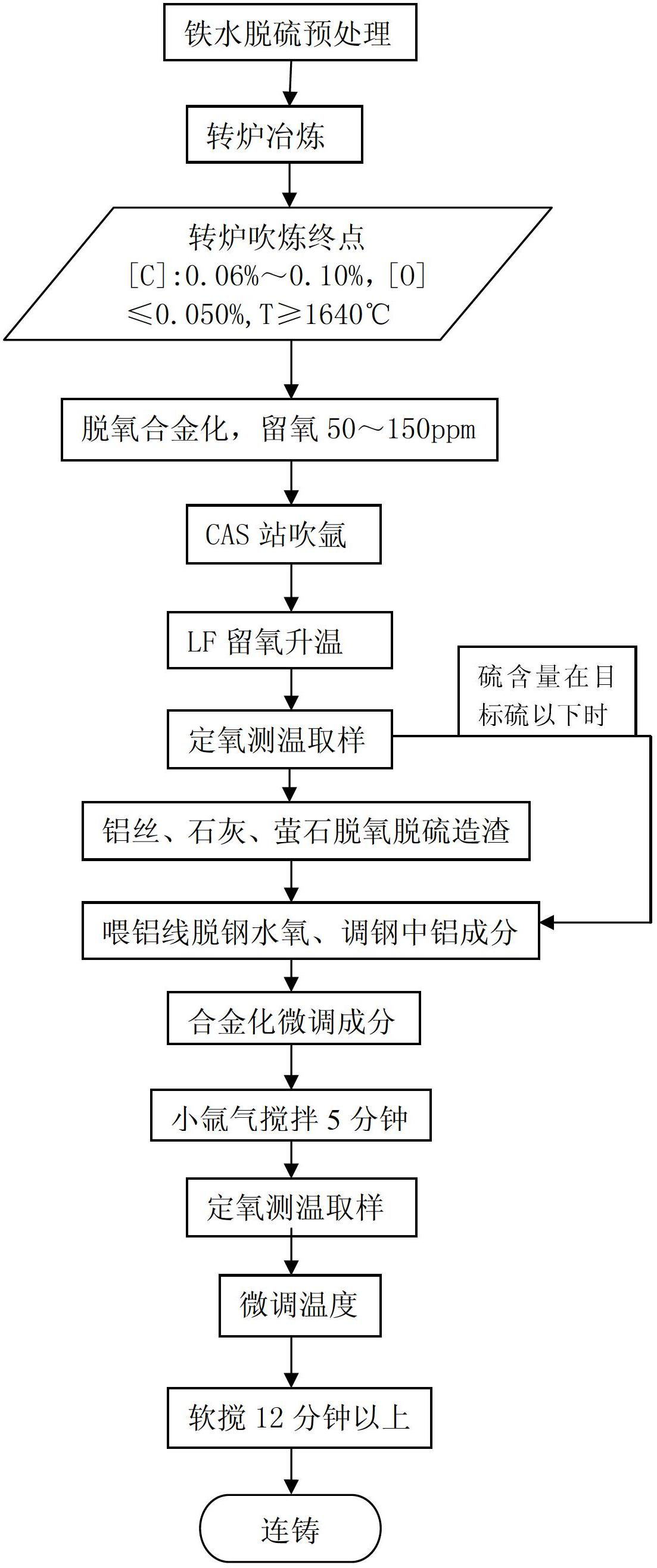

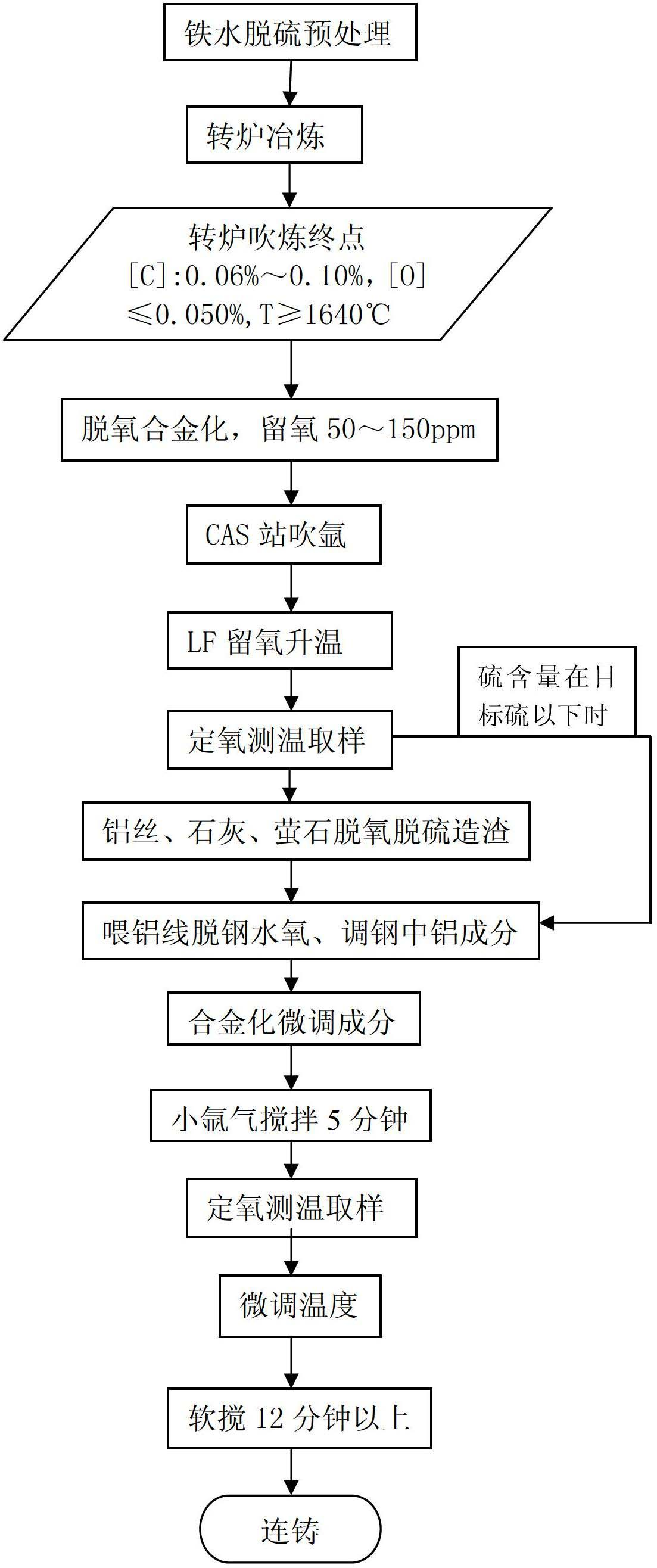

[0022] The low-silicon steel smelting silicon content control technological process of the present embodiment is as follows figure 1 shown, including:

[0023] Converter smelting process:

[0024] ①Deep desulphurization operation: The incoming molten iron is pretreated by desulfurization and cleaned of slag, requiring [S]0.002%; controlling impurities in scrap steel, reducing sulfur content in converter steel, reducing the desulfurization burden of LF process to create strong reduction slag, and preventing strong reduction Atmosphere, long-time refining and other factors reduce the silicon in the top slag of the ladle, causing the molten steel to return to silicon;

[0025] ②End point operation: improve the hit rate of one-time carbon drawing, avoid point blowing, prevent molten steel from overoxidation, control the oxygen in the steel by controlling the carbon at the end point of the converter, and improve the tapping of the converter as much as possible under the condition ...

Embodiment 2

[0034] The low-silicon steel smelting silicon content control technological process of the present embodiment is as follows figure 1 shown, including:

[0035] Converter smelting process:

[0036] ①Deep desulphurization operation: The incoming molten iron is pretreated by desulfurization and cleaned of slag, requiring [S] 0.0015%; control impurities in scrap steel, reduce sulfur content in converter steel, reduce the desulfurization burden of LF process to create strong reduction slag, and prevent strong reduction Atmosphere, long-time refining and other factors reduce the silicon in the top slag of the ladle, causing the molten steel to return to silicon;

[0037] ②End point operation: improve the hit rate of one-time carbon drawing, avoid point blowing, prevent molten steel from overoxidation, control the oxygen in the steel by controlling the carbon at the end point of the converter, and improve the tapping of the converter as much as possible under the condition of satisf...

Embodiment 3

[0046] The low-silicon steel smelting silicon content control technological process of the present embodiment is as follows figure 1 shown, including:

[0047] Converter smelting process:

[0048] ①Deep desulphurization operation: The incoming molten iron is pretreated by desulfurization and cleaned of slag, requiring [S] 0.001%; controlling impurities in scrap steel, reducing sulfur content in converter steel, reducing the desulfurization burden of LF process to create strong reduction slag, and preventing strong reduction Atmosphere, long-time refining and other factors reduce the silicon in the top slag of the ladle, causing the molten steel to return to silicon;

[0049] ②End point operation: improve the hit rate of one-time carbon drawing, avoid point blowing, prevent molten steel from overoxidation, control the oxygen in the steel by controlling the carbon at the end point of the converter, and improve the tapping of the converter as much as possible under the conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com