Rare earth containing low-cost seamless steel pipe for L415N pipeline and production method thereof

A technology for seamless steel pipes and production methods, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., and can solve the problems that the seamless pipe manufacturing method has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Raw materials by weight percentage: 90% blast furnace hot metal, 10% high-quality steel scrap.

[0044] The sequence of the production process is: molten iron pretreatment→top-bottom combined blowing converter smelting→LF furnace refining→VD vacuum treatment→round billet continuous casting→cutting→tube billet heating→piercing→continuous rolling→fixing (stretching and reducing) diameter→cooling→ Sawing → heat treatment → straightening → flaw detection → chamfering.

[0045] The specific production process is briefly described as follows:

[0046] 90 tons of blast furnace molten iron was pretreated with "metal magnesium powder" for desulfurization and deoxidation, so that the S content in the molten iron was reduced to less than (weight percent) 0.010%;

[0047] Mix the 90 tons of pretreated molten iron into a 100-ton top-bottom combined blown converter, add 10 tons of high-quality steel scrap, and then use the single slag process for smelting. The final slag basicity is...

Embodiment 2

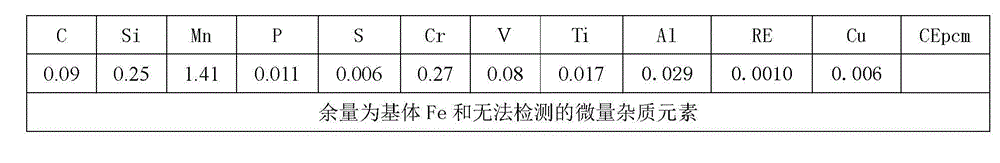

[0068] The ratio of raw materials, production process, etc. and other technical indicators of Example 2 are the same as those of Example 1, the difference is the chemical composition content of the tube blank, the final rolling and sizing temperature and the steel pipe specification (the specification is ф114.3mm× 7.90mm), the chemical composition test results (weight %) are shown in Table 4:

[0069] Table 4 Test results of chemical composition (weight %)

[0070]

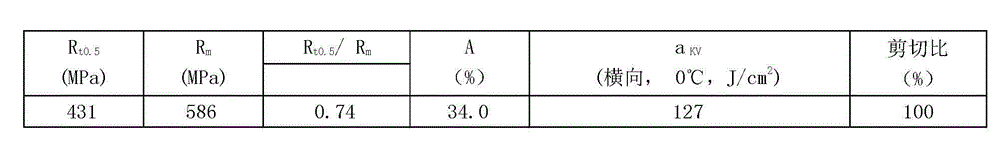

[0071] The final rolling and sizing temperature is 857°C, and the test results of the mechanical properties of the seamless steel pipe are shown in Table 5.

[0072] Table 5 Test results of mechanical properties of steel pipes

[0073]

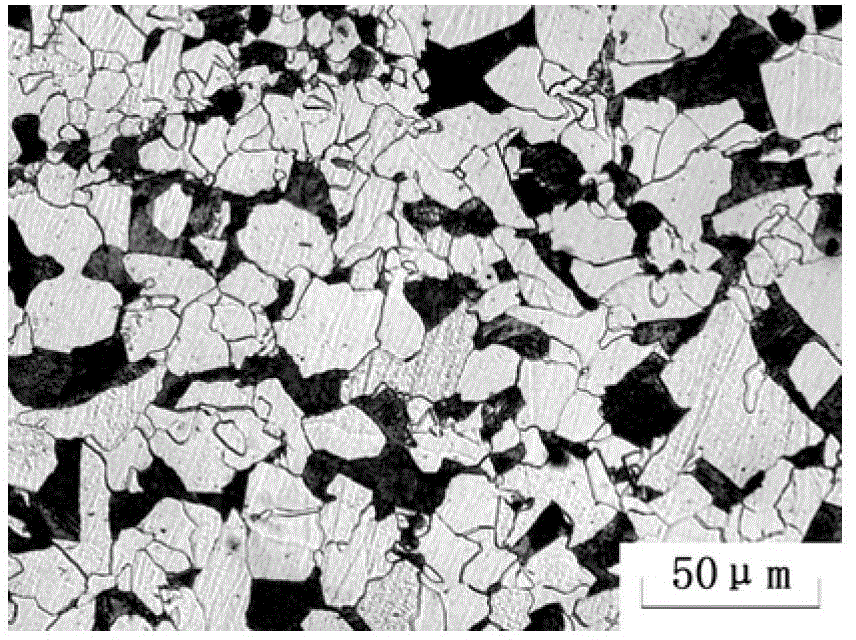

[0074] The structure is ferrite + pearlite, and the grain size is 9.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com