Preparation method of rare earth-containing seamless steel pipe for h2s corrosion resistant pipeline

A technology for seamless steel pipes and pipelines, which is applied in the field of preparation of seamless steel pipes for H2S corrosion-resistant pipelines containing rare earth, can solve the problems of high impurity element content, low melting point, difficulty in smelting and rolling, etc., and achieves excellent anti-HIS performance, The effect of excellent SCC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

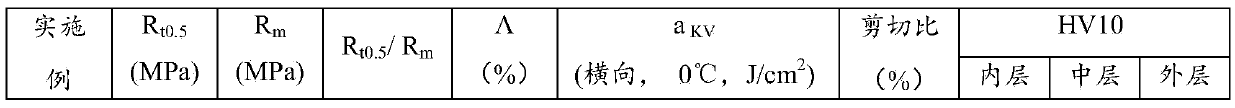

Examples

Embodiment Construction

[0014] The invention adopts blast furnace molten iron and high-quality scrap steel as raw materials. The mass percentage content of blast furnace molten iron is 90%, and the mass percentage content of high-quality steel scrap is 10%. The preparation method of the invention comprises: the production process of the continuous casting round tube billet and the tube making process. The specific production process is as follows:

[0015] The production process of continuous casting round billet includes: molten iron pretreatment→top-bottom combined blowing converter smelting→LF furnace refining→VD vacuum treatment→round billet continuous casting→cutting

[0016] Step S1: Hot metal pretreatment

[0017] 90 tons of blast furnace molten iron is pretreated with "metal magnesium powder" for desulfurization and deoxidation, so that the mass percentage of S in the molten iron after the pretreatment of the molten iron is ≤0.010%.

[0018] Step S2: Converter Smelting with Top and Bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com