Aluminum alloy plate for battery case and battery case made from same

The technology of an aluminum alloy plate and battery shell is used in the direction of battery box/jacket, metal rolling, battery pack component and other directions. Low content and other issues to achieve the effect of improving welding, improving pressure resistance, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Next, specific examples of the present invention will be explained.

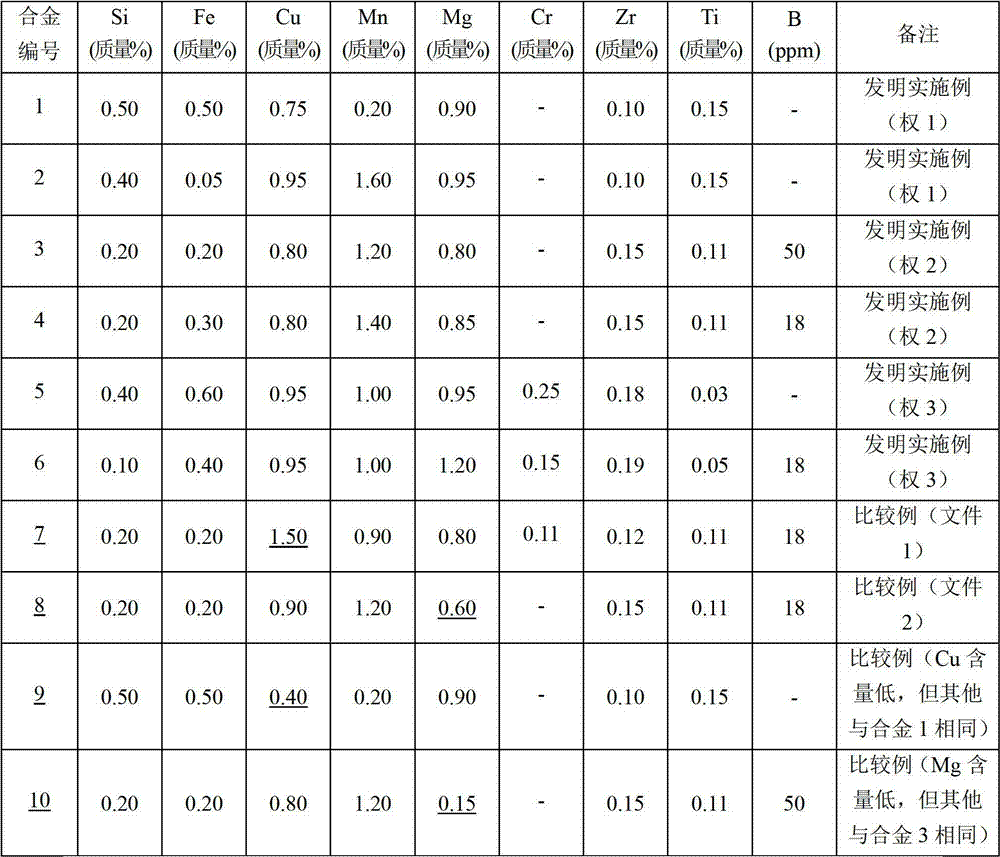

[0058] The aluminum alloy melt is produced by the semi-continuous method, and cast into a thickness of 530mm and a width of 1100mm under the following conditions: 2.5-3.0 liters / cm-min of cooling water from the mold, and the ingot drawing rate of 40-60mm / min. Zr was added using an Al-Zr matrix alloy, Ti was added using an Al-Ti matrix alloy, and B was added using an Al-Ti-B matrix alloy. The composition is shown in Table 1.

[0059] Table 1

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com