Comprehensive iron-aluminium paragenetic mineral utilization method

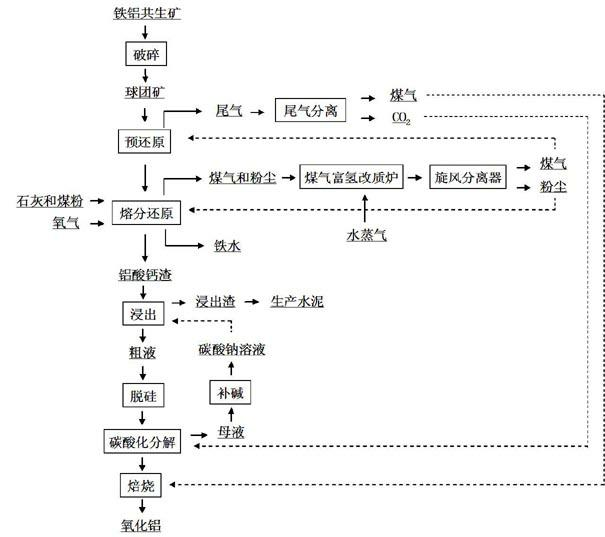

A technology of iron-aluminum symbiotic ore and ore powder, which is applied in the field of metallurgy, can solve the problems of high price, high production cost, and difficult effective separation, and achieve the effects of high-efficiency dissociation extraction, low production cost, and improved dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. First, the weight percentage containing Al 2 o 3 20%, Fe 2 o 3 50%, SiO 2 5%, the iron-aluminum paragenetic ore that is impurities is crushed to 2-5mm, and then the ore powder is ground to a particle size of -0.074mm, accounting for more than 85%. Add mineral powder to the rotating disc pelletizer, add water to make cue balls, and then add water and materials continuously to make the cue balls grow and dry to form pellets. The pellets are placed in the pre-reduction reactor, and the reduction gas is introduced for pre-reduction to obtain the pre-reduction ore. The composition of the reduction gas contains 70% CO, H 2 30%

[0024] Among them, the reduction temperature is 850°C, the reduction time is 180min, and the pre-reduction reactor is a rotary hearth furnace or a shaft furnace; the Fe in the pre-reduction ore is 2 o 3 The weight content of FeO is 5%, the weight content of FeO is 60%, and the weight content of metallic iron is 8%. The tail gas generat...

Embodiment 2

[0030] 1. First, the composition contains Al by weight percentage 2 o 3 40%, Fe 2 o 3 30%, SiO 2 15%, the iron-aluminum paragenetic ore which is impurities is crushed to 2-5mm, and then the ore powder is ground to a particle size of -0.074mm, accounting for more than 85%. Put the mineral powder into the rotating disc pelletizer, add water to make cue balls, and then add water and materials continuously, so that the cue balls grow up and then dry to form pellets. The pellets are placed in the pre-reduction reactor, and the reducing gas is introduced into the pre-reduction to obtain the pre-reduced ore. The above-mentioned reducing gas composition contains 90% CO, H 210%, wherein the reduction temperature is 1050°C, the reduction time is 30min, and the pre-reduction reactor is a rotary hearth furnace or a shaft furnace; the tail gas generated during the pre-reduction process is separated to form CO 2 and gas. of which CO 2 For carbonation decomposition, excess CO 2 Co...

Embodiment 3

[0036] 1. First, the composition contains Al by weight percentage 2 o 3 30%, Fe 2 o 3 40%, SiO 2 10%, the iron-aluminum paragenetic ore that is impurities is crushed to 2-5mm, and then the ore powder is ground to a particle size of -0.074mm, accounting for more than 85%. Add mineral powder to the rotating disc pelletizer, add water to make cue balls, and then add water and materials continuously to make the cue balls grow and dry to form pellets. The pellets are placed in the pre-reduction reactor, and the reduction gas is fed into the pre-reduction to obtain the pre-reduction ore. The reduction gas composition contains 80% CO, H 2 20%, wherein the reduction temperature is 950°C, the reduction time is 90min, and the pre-reduction reactor is a rotary hearth furnace or a shaft furnace; the Fe in the pre-reduction ore obtained by the above method 2 o 3 The weight content of FeO is 7.5%, the weight content of FeO is 50%, and the weight content of metallic iron is 5%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com