Energy-saving and efficiency-improving composite reagent for limestone gypsum desulfurization

A compound reagent and gypsum method technology, which is applied in the field of flue gas purification, can solve problems such as foaming problems that have not been considered, and achieve the effects of adjustable formula, improved utilization rate, and reduced moisture content of gypsum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

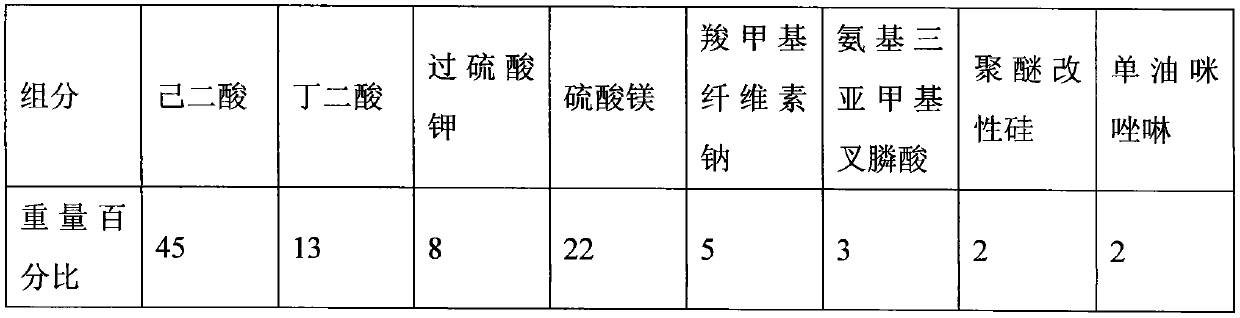

[0021] The energy-saving and efficiency-enhancing compound reagent is prepared according to the formula in Table 1:

[0022] Table 1 Compound Reagent Formula 1

[0023]

[0024] Simulated flue gas composition SO 2 : 0.4%, CO 2 : 11%, O 2 : 6%, N 2 : 82.6%, absorption temperature 55°C, liquid-gas ratio 10, calcium-sulfur ratio 1.01. The flue gas desulfurization efficiency is 73% when no energy-saving and efficiency-enhancing compound reagent is added, and the CaSO in the gypsum product 4 2H 2 The O content is 89.1%, and the water content is 12.5%. The energy-saving and efficiency-enhancing composite reagent is added at 700 mg / L, and the pH of the slurry is maintained at 5.2-6.0. At this time, the flue gas desulfurization efficiency is increased to 94%, and the CaSO 4 2H 2 The O content is 91.1%, and the water content is 9.9%.

specific Embodiment 2

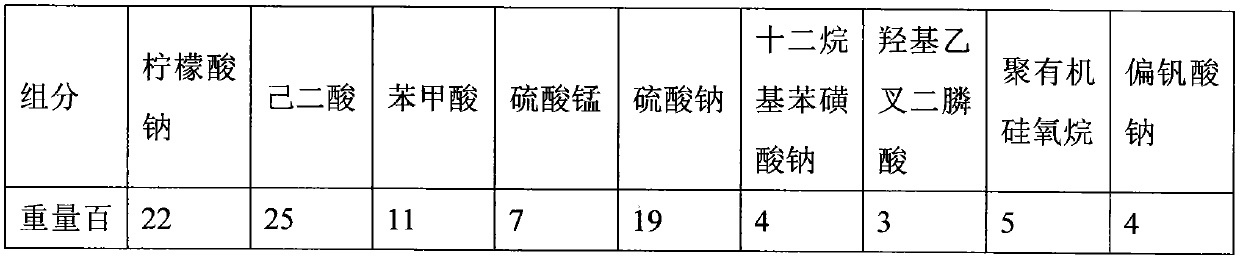

[0025] The energy-saving and efficiency-enhancing compound reagent is prepared according to the formula in Table 2:

[0026] Table 2 Compound Reagent Formula 2

[0027]

[0028]

[0029] Simulated flue gas composition SO 2 : 0.5%, CO 2 : 12%, O 2 : 8%, N 2 : 79.5%. The absorption temperature is 55°C, the liquid-gas ratio is 12, the calcium-sulfur ratio is 1.01, and the flue gas desulfurization efficiency is 71% when no energy-saving and efficiency-enhancing compound reagent is added, and the CaSO in the gypsum product 4 2H 2 The O content is 89.3%, the water content is 12.3%, the energy-saving and efficiency-enhancing composite reagent is added at 800 mg / L, and the pH of the slurry is maintained at 5.2-6.0. At this time, the flue gas desulfurization efficiency increases to 91%, and the CaSO in the gypsum product 4 2H 2 The O content is 90.5%, and the water content is 10.1%.

specific Embodiment 3

[0030] The energy-saving and efficiency-enhancing compound reagent is prepared according to the formula in Table 3:

[0031] Table 3 Compound Reagent Formula 3

[0032]

[0033] Simulated flue gas composition SO 2 : 0.3%, CO 2 : 12%, O 2 : 7%, N 2 : 80.7%. The absorption temperature is 55°C, the liquid-gas ratio is 10, the calcium-sulfur ratio is 1.01, and the flue gas desulfurization efficiency is 84% when no energy-saving and efficiency-enhancing compound reagent is added, and the CaSO in the gypsum product 4 2H 2 The O content is 89.0%, and the water content is 12.2%. The energy-saving and efficiency-enhancing composite reagent is added at 800mg / L, and the pH of the slurry is maintained at 5.2-6.0. At this time, the flue gas desulfurization efficiency increases to 97%, and the CaSO 4 2H 2 The O content is 90.9%, and the water content is 9.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com