Device for detecting comprehensive performance of ball screw assembly in loaded state

A ball screw pair, comprehensive performance technology, applied in the direction of measuring devices, machine gear/transmission mechanism testing, instruments, etc., can solve the problems of insufficient performance parameters, complicated control methods, high cost, etc., to achieve comprehensive test performance parameters, The effect of wide detection range and comprehensive project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

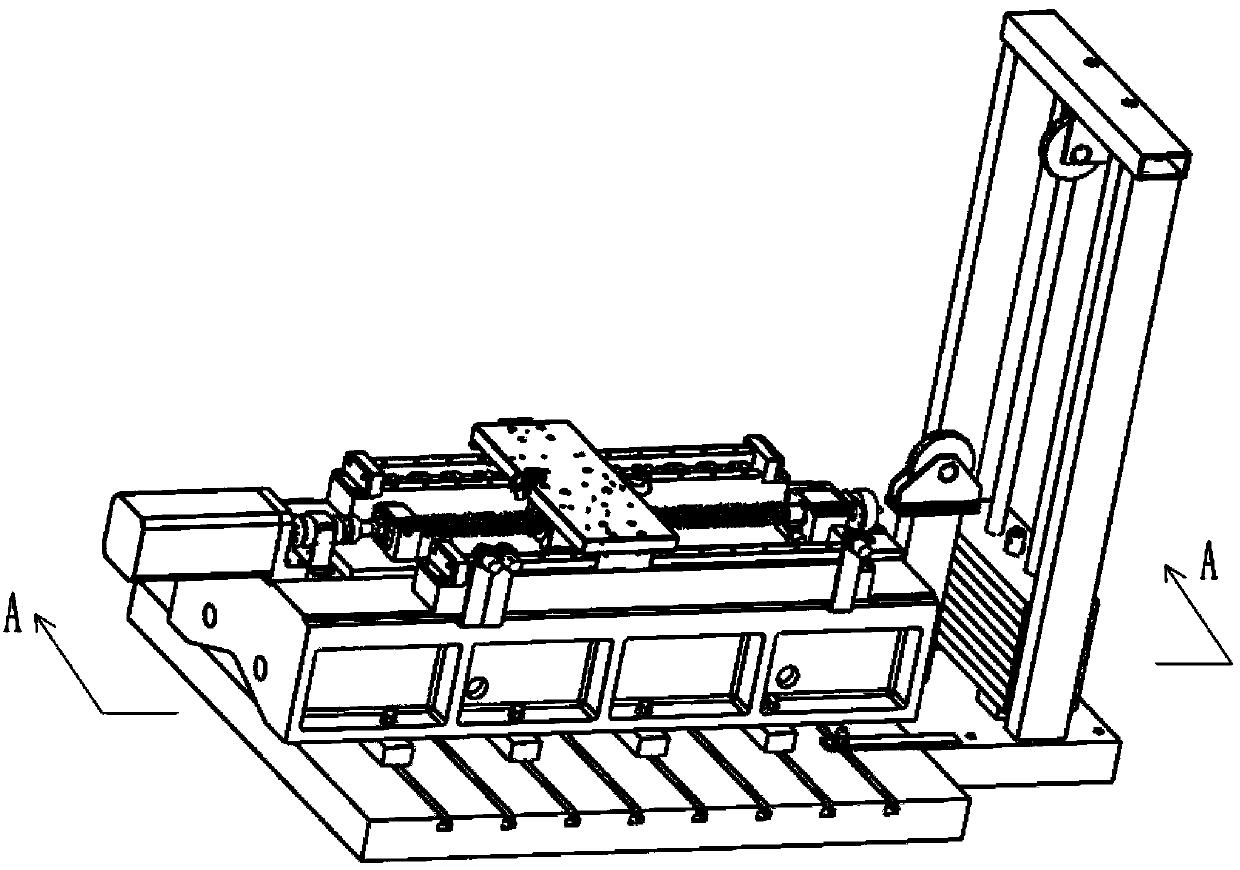

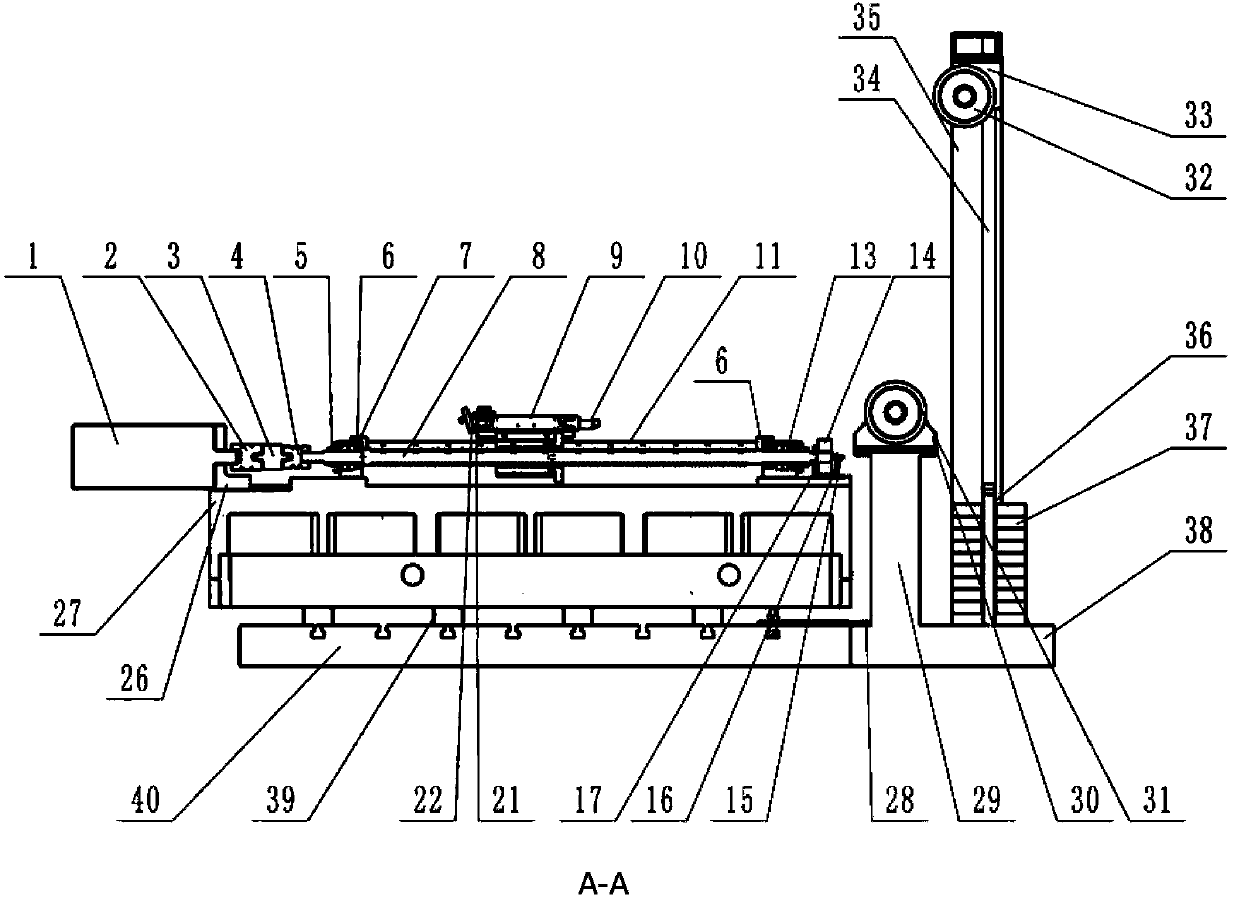

[0024] see figure 1 As shown in -2, the present invention includes a cast iron platform 40 and a test bench body 27 that can be installed with two kinds of different width guide rails. The cast iron platform 40 is provided with a T-shaped slot, and the test bench body 27 is fixed to the cast iron body with bolts through the T-shaped slot. On the platform 40, and between the test bench fuselage 27 and the cast iron platform 40, a machine tool adjustment horn 39 is set. Adjust the horizontality of the test bench as a whole through the level meter and the machine tool to adjust the pad iron 39 .

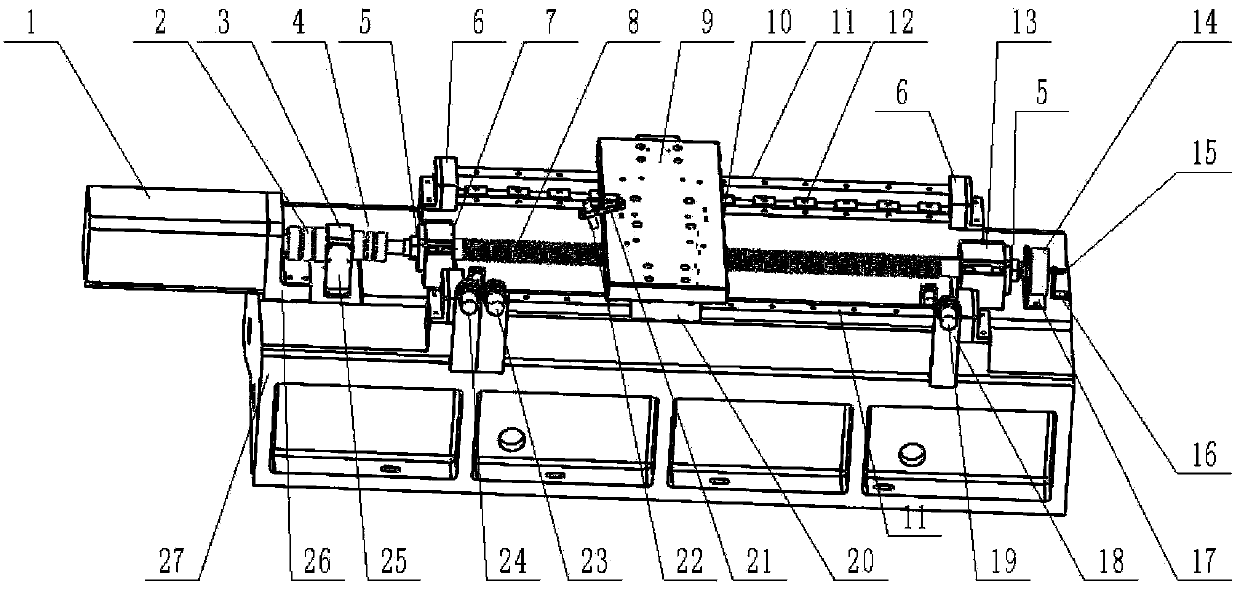

[0025] see image 3 , one end of the test bench body 27 is equipped with a servo motor 1 that provides a power source, and the output shaft of the servo motor 1 passes through the first coupling 2, the dynamic torque sensor 3 and the second coupling 4 and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com