Vermicular cast iron cylinder liner and preparation method thereof

A technology of vermicular graphite cast iron and cylinder liner, which is applied in the field of vermicular graphite cast iron cylinder liner and its preparation, can solve the problems of high production cost of cylinder liner, complicated austempering process, poor strength and wear resistance, etc., and achieves lower production cost and cost-effectiveness. The effect of high and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

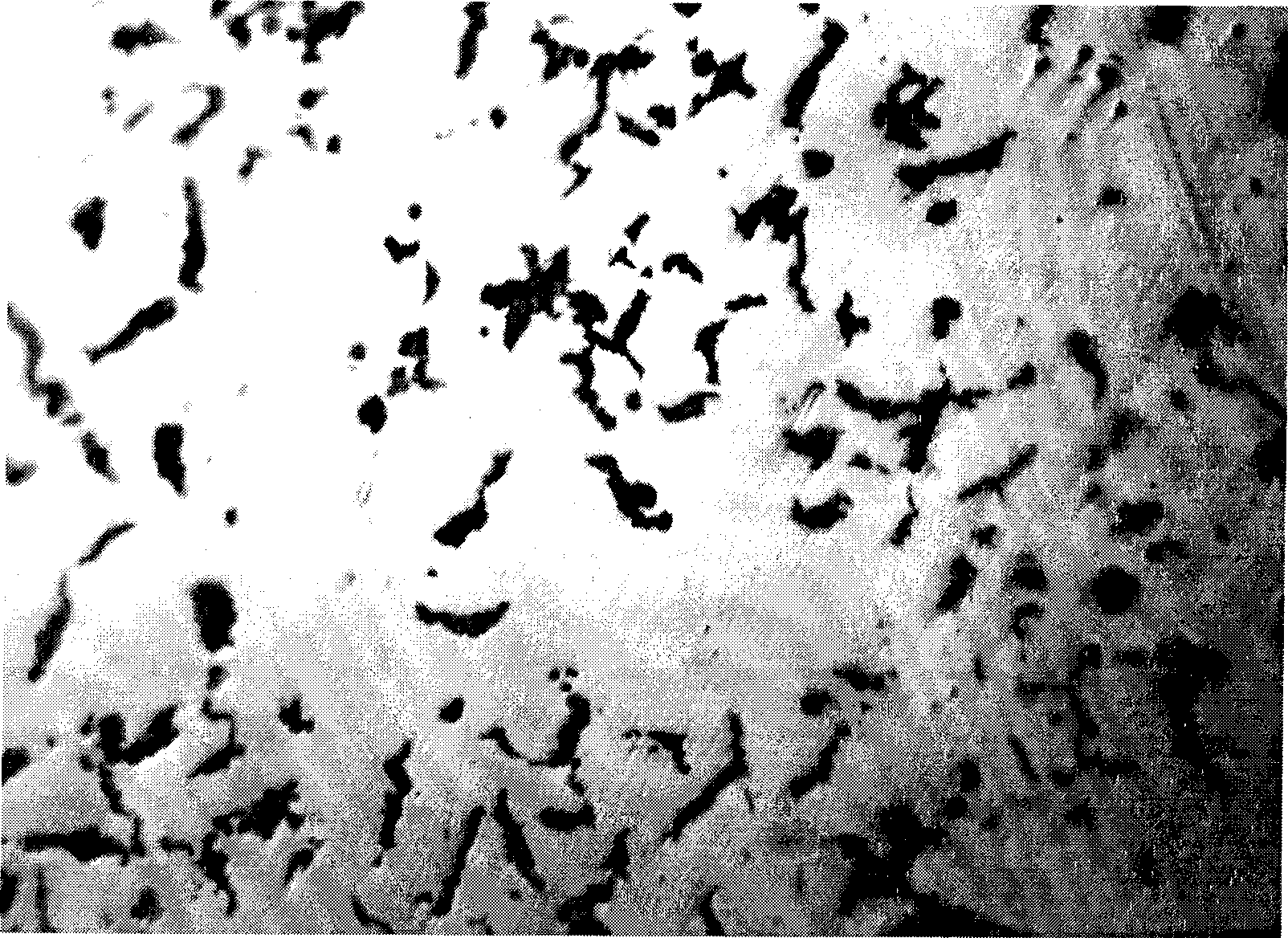

Image

Examples

Embodiment 1

[0028] According to the weight percentage of each chemical composition: carbon 3.75%, sulfur ≤ 0.05%, silicon 1.5%, phosphorus 0.35%, manganese 0.6%, chromium 0.35%, copper 0.4%, and the balance is Fe for batching. The molten iron is smelted in a frequency conversion induction furnace, and the carbon equivalent of the furnace analysis is 4.58. When the fire is fired, 0.6% of the mass of the molten iron is injected into the molten iron to inoculate with a silicon-barium inoculant and 0.4% of a rare-earth silicon-iron-magnesium alloy creeping agent. The molten iron is melted at a temperature of 1432°C; the cylinder liner castings are produced by the conventional process of centrifugal casting of metal mold wet paint. The thickness of the coating is about 2mm, and the mold temperature is 441°C. The cylinder liner of vermicular graphite cast iron is obtained. Its chemical composition is 3.78% carbon, ≤0.05% sulfur, 2.28% silicon, 0.35% phosphorus, 0.6% manganese, 0.36% chromium, an...

Embodiment 2

[0030] According to the weight percentage of each chemical composition: carbon 3.7%, sulfur ≤ 0.05%, silicon 1.4%, phosphorus 0.3%, manganese 0.65%, chromium 0.3%, copper 0.35%, and the balance is Fe for batching. The molten iron is smelted in a frequency conversion induction furnace. The carbon equivalent is 4.51 according to the analysis before the furnace. The temperature is controlled to be 1440 ℃ and the molten iron is released from the furnace; the cylinder liner castings are produced by the conventional process of centrifugal casting of metal mold wet paint. The thickness of the coating is about 2mm, and the mold temperature is 454°C. The cylinder liner of vermicular graphite cast iron is obtained. Its chemical composition is 3.75% carbon, ≤0.05% sulfur, 2.08% silicon, 0.3% phosphorus, 0.61% manganese, 0.3% chromium, and 0.34% copper. The balance is Fe; its tensile strength is 443MPa and hardness is 272HB.

Embodiment 3

[0032] According to the weight percentage of each chemical composition: carbon 3.6%, sulfur ≤ 0.05%, silicon 1.35%, phosphorus 0.25%, manganese 0.75%, chromium 0.25%, copper 0.4%, and the balance is Fe for batching. The molten iron is smelted in a frequency conversion induction furnace. The carbon equivalent of the furnace analysis is 4.43. When the fire is fired, 0.7% silicon barium inoculant and 0.5% rare earth ferrosilicon magnesium alloy creeping agent are poured into the molten iron. The temperature is 1450°C, and the molten iron is released from the furnace; the cylinder liner castings are produced by the conventional process of centrifugal casting of metal mold wet paint. The thickness of the coating is about 2mm, and the mold temperature is 462°C. The cylinder liner of vermicular graphite cast iron is obtained. Its chemical composition is 3.7% carbon, ≤0.05% sulfur, 1.85% silicon, 0.25% phosphorus, 0.75% manganese, 0.27% chromium, and 0.38% copper. The balance is Fe; i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com