High-strength low stress cast nodular cast iron with high elasticity modulus and manufacturing method thereof

A ductile iron, high-elasticity technology, applied in the field of ductile iron, can solve the problems of large amount of spheroidizer and inoculant added, spheroidization, extensive inoculation treatment method, difficulty in high strength and high elastic modulus, etc. body content, increasing tensile strength and elastic modulus, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

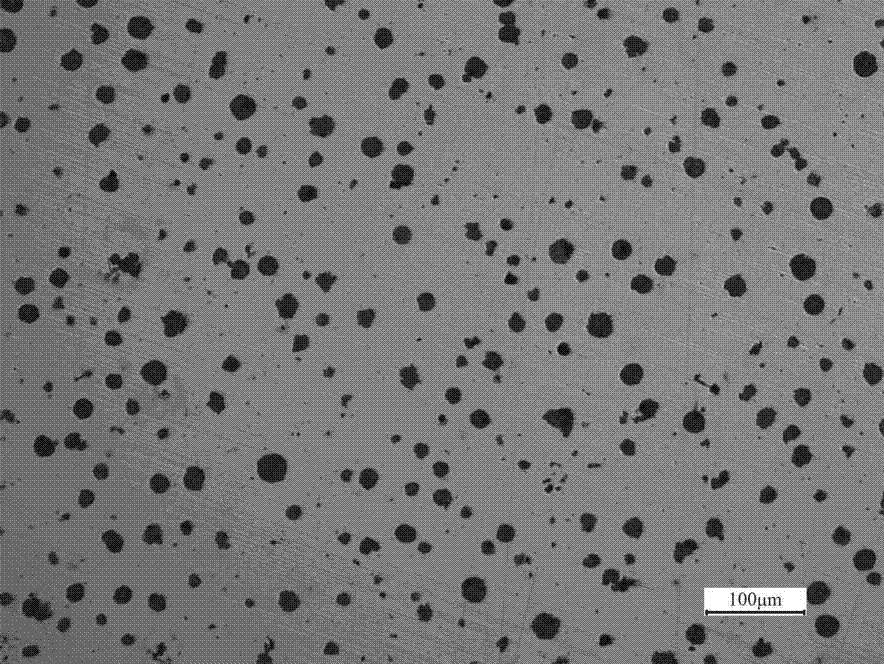

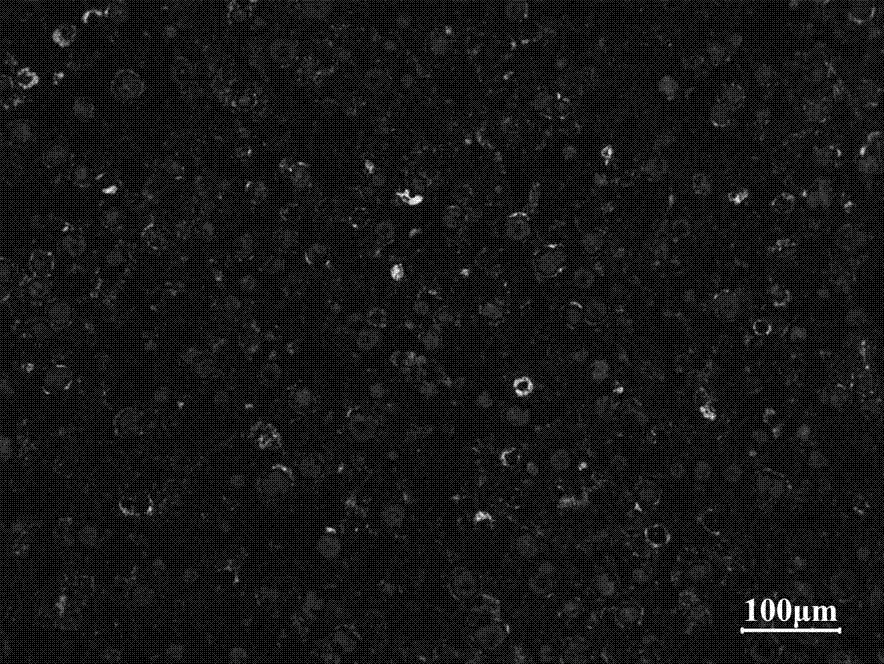

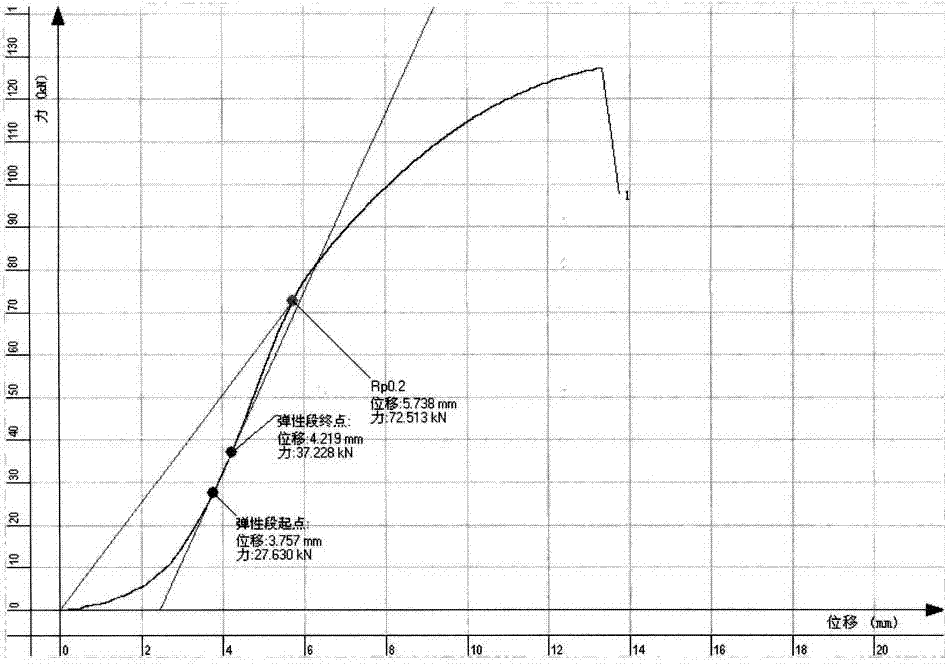

[0027] The preparation composition is C: 3.7%; Si: 2.2%; CE: 4.50%; Mn: 0.5%; P≤0.03%; S≤0.02%; Mg: 0.035%; RE: 0.010%; : 0.06% of ductile iron:

[0028] The first step, modeling: resin sand molding is used, and the surface of the cavity is painted with alcohol-based zirconia paint;

[0029]The second step, raw material preparation: Weigh raw materials according to the weight percentage of high-purity pig iron: carbon steel scrap = 80%: 20%, wherein: the chemical composition of high-purity pig iron is: C: 4.61%; Si: 0.62%; Mn: 0.08%; S: 0.026%; P: 0.011%; Ti: 0.030%; the chemical composition of carbon steel scrap is: C: 0.16%; Si: 0.23%; Mn: 0.44%; S: 0.02%; P: 0.027% ;

[0030] The third step, base iron smelting: preheat high-purity pig iron and carbon steel scrap at 400°C±10°C and put them into an intermediate frequency furnace for melting. After the raw materials are melted, add 75# ferrosilicon to adjust the silicon content of the original iron liquid to 1.2 %, the supe...

Embodiment 2

[0037] The prepared composition is C: 3.8%; Si: 2.1%; CE: 4.55%; Mn: 0.6%; P≤0.03%; S≤0.02%; Mg: 0.04%; RE: 0.014%; : 0.06% of ductile iron:

[0038] The first step, modeling: resin sand molding is used, and the surface of the cavity is painted with alcohol-based graphite paint;

[0039] Second step, raw material preparation: take raw material by weight percentage of high-purity pig iron: carbon steel scrap=82%:18%, wherein the chemical composition of used high-purity pig iron and the chemical composition of carbon steel scrap are with embodiment 1;

[0040] The third step, base iron smelting: Preheat the high-purity pig iron and carbon scrap at 400°C±10°C and put them into the intermediate frequency furnace for melting. After the raw materials are melted, add 75# ferrosilicon to adjust the silicon content of the original iron liquid to 1.16. %, the superheated temperature of molten iron is 1514°C, then stir and remove slag;

[0041] The fourth step, alloying treatment: add ...

Embodiment 3

[0047] The preparation composition is C: 3.9%; Si: 2.0%; CE: 4.60%; Mn: 0.5%; P≤0.03%; S≤0.02%; Mg: 0.05%; RE: 0.017%; : 0.05% of ductile iron:

[0048] The first step, modeling: resin sand molding is used, and the surface of the cavity is painted with alcohol-based zirconia paint;

[0049] Second step, raw material preparation: take raw material by weight percentage of high-purity pig iron: carbon steel scrap=84%:16%, wherein the chemical composition of used high-purity pig iron and the chemical composition of carbon steel scrap are with embodiment 1;

[0050] The third step, base iron smelting: Preheat high-purity pig iron and carbon scrap steel at 400°C±10°C and put them into an intermediate frequency furnace for melting. After the raw materials are melted, add 75# ferrosilicon to adjust the silicon content of the original iron liquid to 1.0 %, the superheated temperature of molten iron is 1517°C, then stir and remove slag;

[0051] The fourth step, alloying treatment: ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com