As-cast high-toughness ferrite nodular iron and production method thereof

A technology of nodular cast iron and production method, which is applied to as-cast high-toughness ferritic nodular cast iron and its production field, can solve the problems of slow cooling rate, reduction in the number of graphite nodules, inoculation and recession, etc., and achieves short production cycle and low production cost. , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

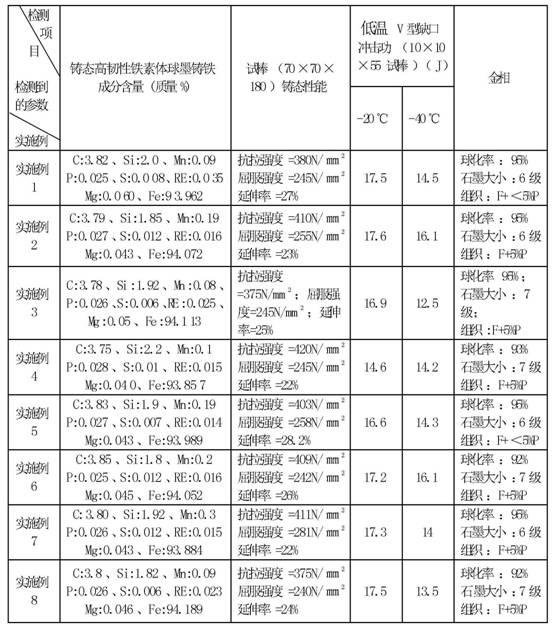

[0037] An as-cast high-toughness ferritic ductile iron, the composition of which is: C: 3.75-3.85% by mass, Si: 1.8-2.2% by mass, Mn: 0.08-0.3% by mass, P:<0.03% by mass, S:< 0.015% by mass, RE: 0.015-0.035% by mass, Mg: 0.04-0.06% by mass, and the balance is iron and unavoidable trace impurities.

[0038] A production method of as-cast high-toughness ferritic nodular cast iron, which comprises the following process steps:

[0039] 1. Melting

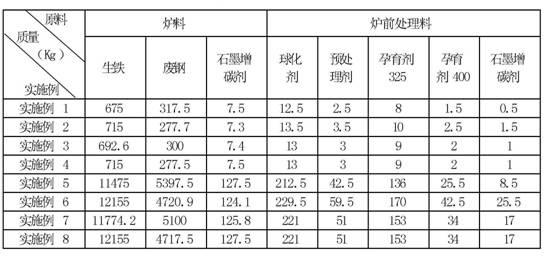

[0040] A. Take the furnace charge. The composition ratio of the furnace charge is: 67.5-71.5% by mass of pig iron, 27.75-31.75% by mass of steel scrap, and 0.73-0.75% of graphite recarburizer. The best ratio is 69.26% by mass of pig iron and 30% by mass of steel scrap , graphite recarburizer 0.74% by mass;

[0041] B. Add pig iron to the intermediate frequency induction furnace to start the furnace for smelting. After the pig iron is melted, add scrap steel and graphite recarburizer. The temperature of the molten iron in the furnace i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com