Heat source or heat sink unit with thermal ground coupling

a technology of heat sink and heat source, which is applied in the direction of geothermal energy generation, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of high installation cost, high cost, and inability to use, and achieve the effect of preventing corrosion damage, promoting corrosion of drive-pipe segments, and avoiding corrosion damages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

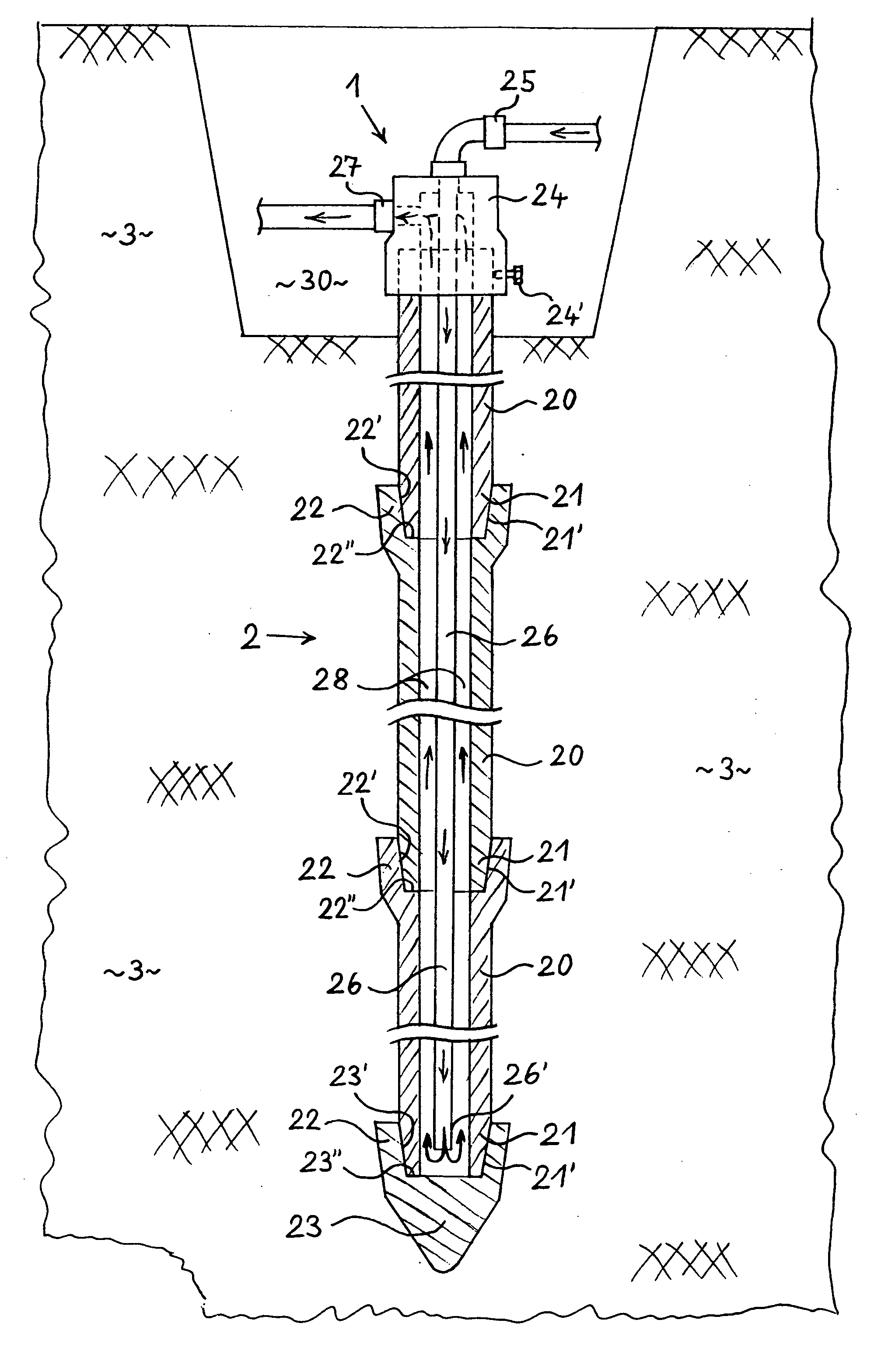

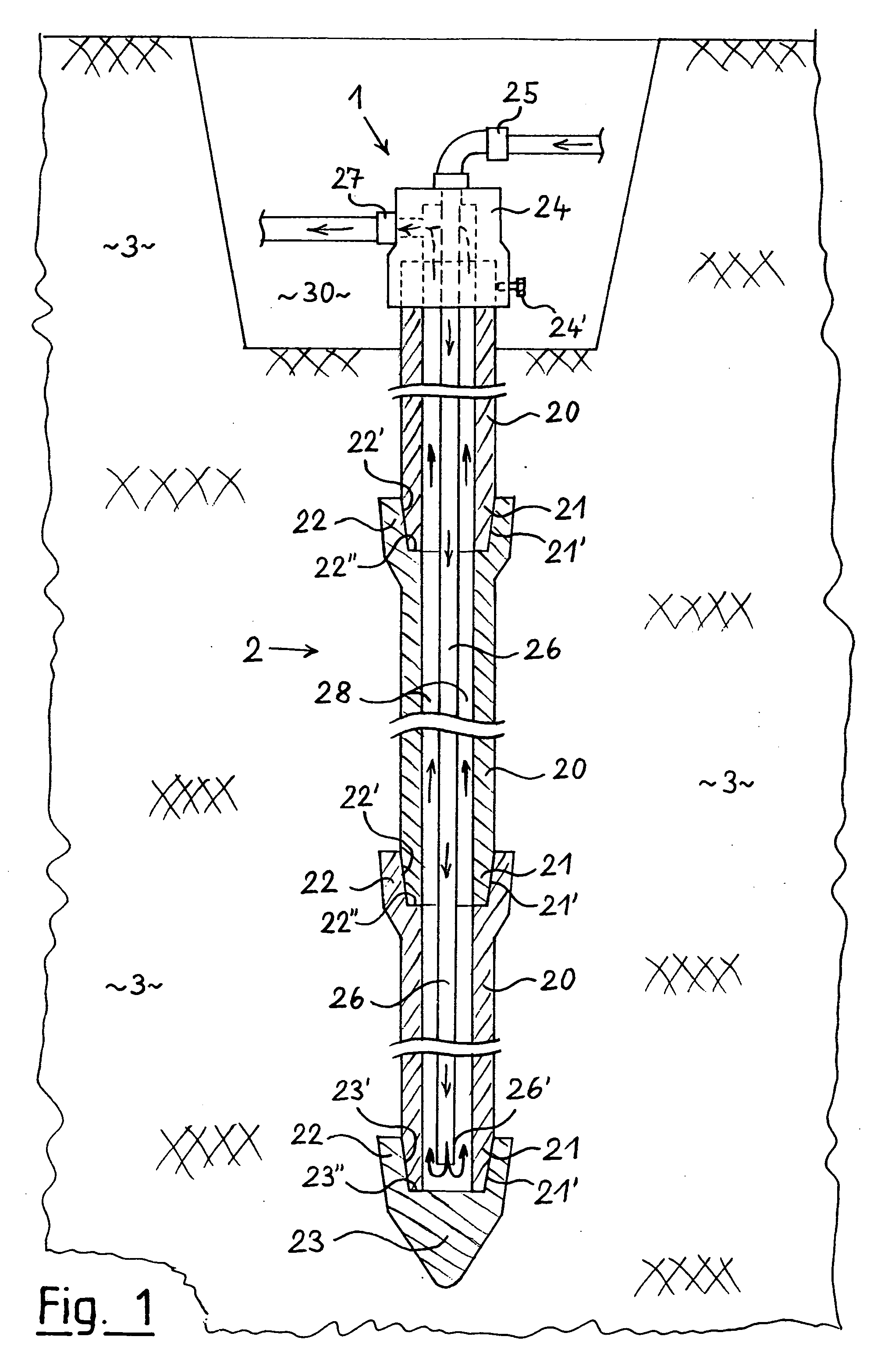

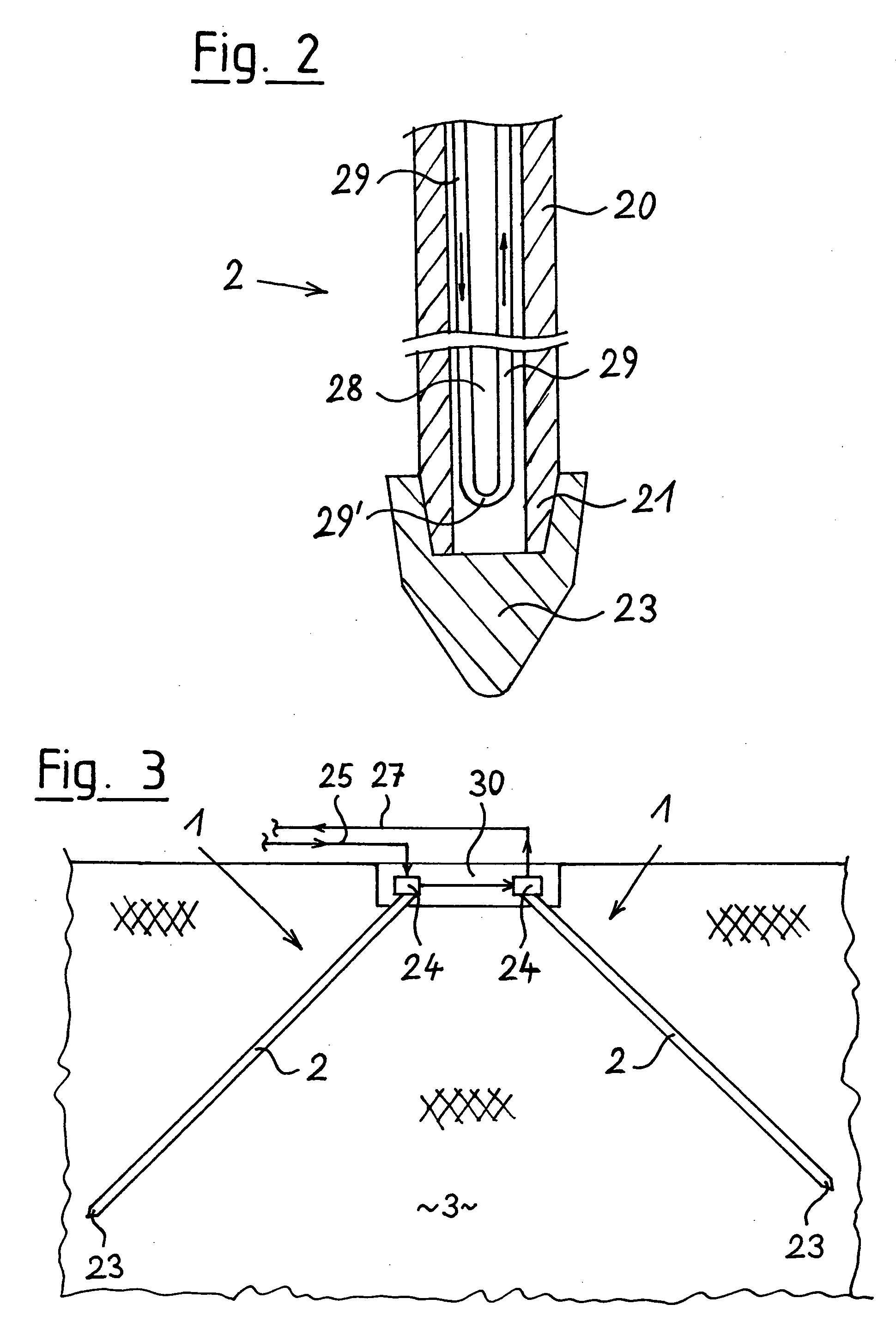

[0035] According to the executive example shown in FIG. 1, the ground probe 1 consists of a probe shaft 2 that is composed of several drive-pipe segments 20. To form the ground probe 1, the required number of drive-pipe segments 20 are initially driven successively into the ground 3 in a relatively small building pit 30 that has been prepared beforehand, for example by means of a hydraulic hammer mounted to an excavator arm or a carriage. At first, the drive-pipe segment 20 that is the bottommost in the drawing is provided with a probe tip 23 in order to ensure that said drive-pipe segments 20 can be driven into the ground 3 with as low a resistance as possible and as easily and quickly as possible. Herein, the probe tip 23 is tightly connected to the forward end 21 of the lower drive-pipe segment 20. As soon as the first drive-pipe segment 20 has been driven into the ground 3 almost completely, a second drive-pipe segment 20 is fitted; thereafter, the first and second drive-pipe se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com