High-strength high-toughness ductile cast iron 600-10 and production method thereof

A nodular cast iron, production process technology, applied to nodular cast iron. It can solve the problems of harsh casting shape, large manpower and material resources and time, equipment space and equipment weight increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

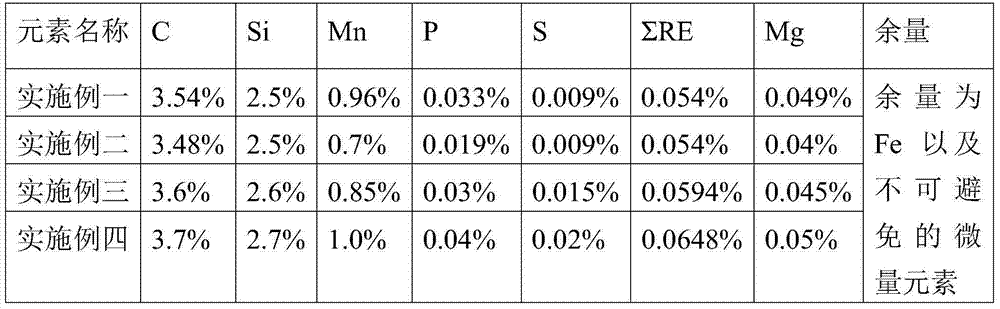

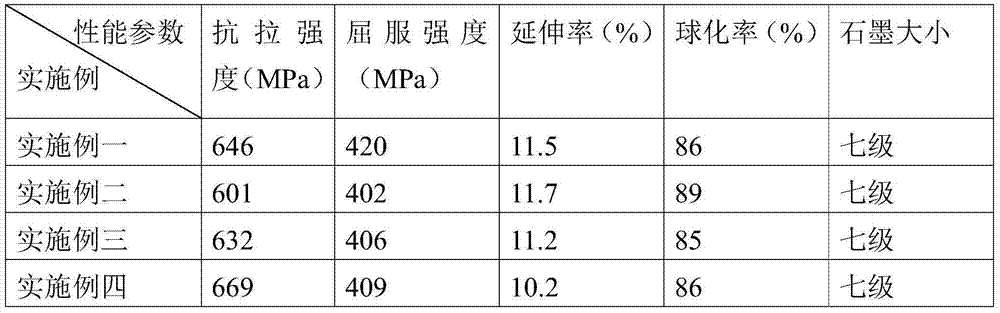

Embodiment 1

[0035] The high-strength and high-toughness ductile iron 600-10 in Example 1 is made through the following steps:

[0036]S1: Batching process, the raw materials used include Q12 pig iron, recycled material, steel scrap, ferrosilicon, ferromanganese, nodulizer and inoculant, and the ratio is as follows: Q12 pig iron: 66%, recycled material: 16.3%, scrap steel: 14 %, ferrosilicon: 0.9%, ferromanganese: 1%, nodulizer: 1.76%, inoculant: 0.04%;

[0037] S2: Smelting process, weigh Q12 pig iron, returned material and steel scrap according to the ratio in S1; start the power supply of the intermediate frequency induction furnace, add Q12 pig iron when the furnace temperature rises to 400°C and heat it to Q12 melting point; then add scrap steel and returned material And raise the temperature to 1400°C; use the metal element furnace front spectrum analyzer to detect the metal composition in the furnace, add 0.9% ferrosilicon and 1% ferromanganese according to the test results, and con...

Embodiment 2

[0050] The high-strength and high-toughness ductile iron 600-10 in embodiment two is made through the following steps:

[0051] S1: Batching process, the raw materials used include Q12 pig iron, recycled material, steel scrap, ferrosilicon, ferromanganese, nodulizer and inoculant, and the ratio is as follows: Q12 pig iron: 65%, recycled material: 15.56%, scrap steel: 15.57 %, ferrosilicon: 0.87%, ferromanganese: 1%, nodulizer: 1.96%, inoculant: 0.04%;

[0052] S2: Smelting process, weigh Q12 pig iron, returned material and steel scrap according to the ratio in S1; start the power supply of the intermediate frequency induction furnace, add Q12 pig iron when the furnace temperature rises to 400°C and heat it to Q12 melting point; then add scrap steel and returned material And raise the temperature to 1400°C; use the metal element furnace front spectrum analyzer to detect the metal composition in the furnace, add 0.87% ferrosilicon and 1% ferromanganese according to the test resu...

Embodiment 3

[0065] The high-strength and high-toughness nodular cast iron 600-10 in embodiment three is made through the following steps:

[0066] S1: Batching process, the raw materials used include Q12 pig iron, recycled material, steel scrap, ferrosilicon, ferromanganese, nodulizer and inoculant, and the ratio is as follows: Q12 pig iron: 68%, recycled material: 17.05%, scrap steel: 11.06 %, ferrosilicon: 0.9%, ferromanganese: 1%, nodulizer: 1.95%, inoculant: 0.04%;

[0067] S2: Smelting process, weigh Q12 pig iron, returned material and steel scrap according to the ratio in S1; start the power supply of the intermediate frequency induction furnace, add Q12 pig iron when the furnace temperature rises to 400°C and heat it to Q12 melting point; then add scrap steel and returned material And raise the temperature to 1400°C; use the metal element furnace front spectrum analyzer to detect the metal composition in the furnace, add 0.9% ferrosilicon and 1% ferromanganese according to the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com