Improved device for recovering, processing and recycling acidic waste gas

A recovery treatment and circulation device technology, applied in the direction of dust removal, cleaning methods and appliances, separation of dispersed particles, etc., can solve the problems of environmental pollution, consumption of large alkaline resources, failure to ensure the rate of waste gas compliance, etc., to reduce production costs, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

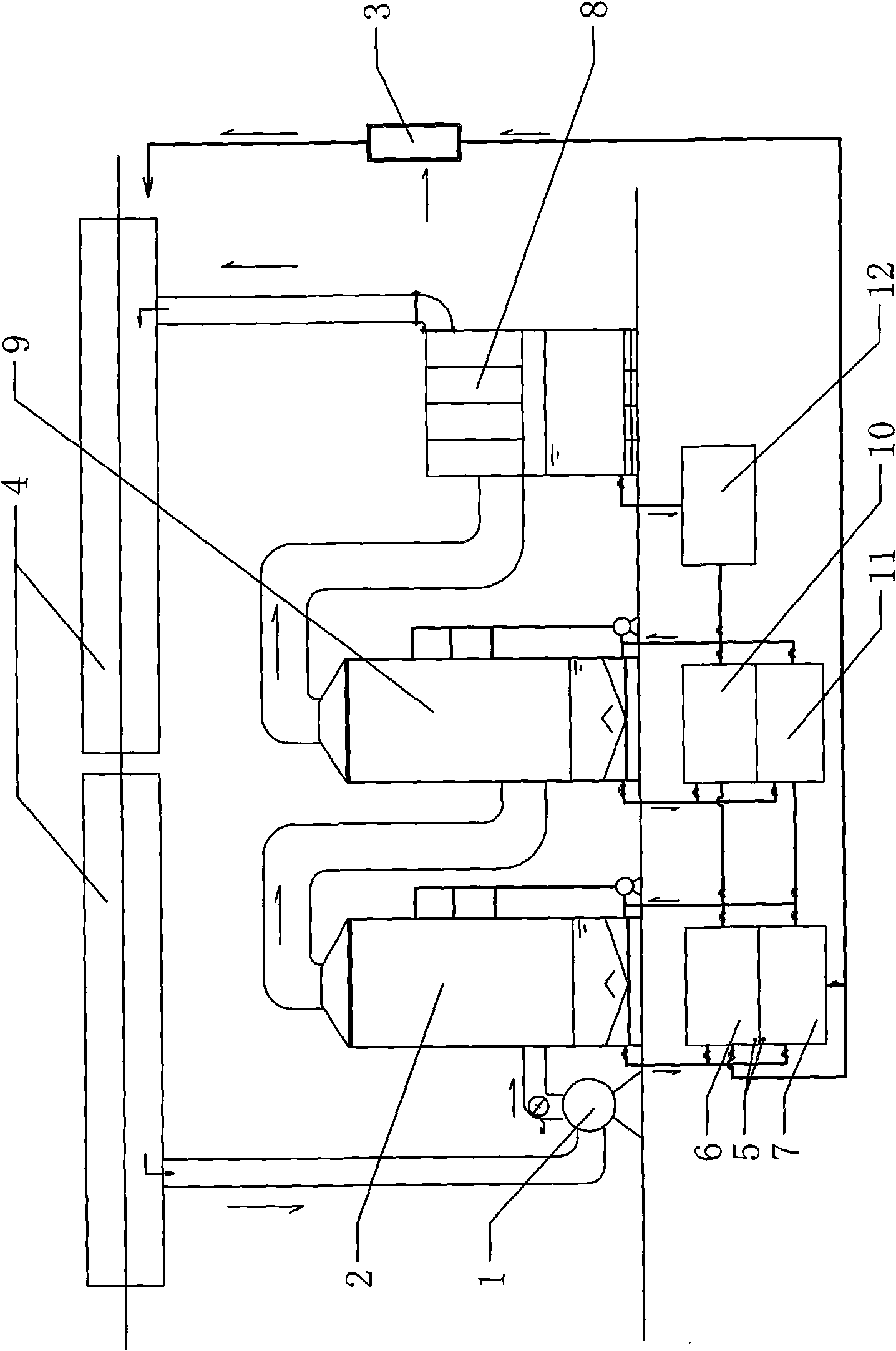

[0008] See figure 1 , the present invention comprises blower fan 1, waste gas absorption device, and waste gas absorption device comprises waste gas absorption tower and recovery tank, fan 1 pipeline is connected waste gas absorption tower, and recovery tank is connected with waste gas absorption tower lower pipeline and is connected with mixing device 3 pipelines, mixes The device 3 is connected with the pickling production line 4 . In the present invention, the waste gas absorption device is provided with two sets, which are respectively a primary absorption device and a secondary absorption device; wherein the primary absorption device includes a primary waste gas absorption tower 2, primary recovery tanks 6 and 7, and primary recovery tanks 6 and 7 are connected in parallel Afterwards, it forms a circulation loop with the primary waste gas absorption tower 2; the secondary absorption device includes a secondary waste gas absorption tower 9, secondary recovery tanks 10, 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com