Hot rolled steel plate with excellent low-temperature toughness for thick submerged pipeline and production method of hot rolled steel plate

A low-temperature toughness, submarine pipeline technology, used in metal rolling, metal rolling, rolling mill control devices, etc., to achieve excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

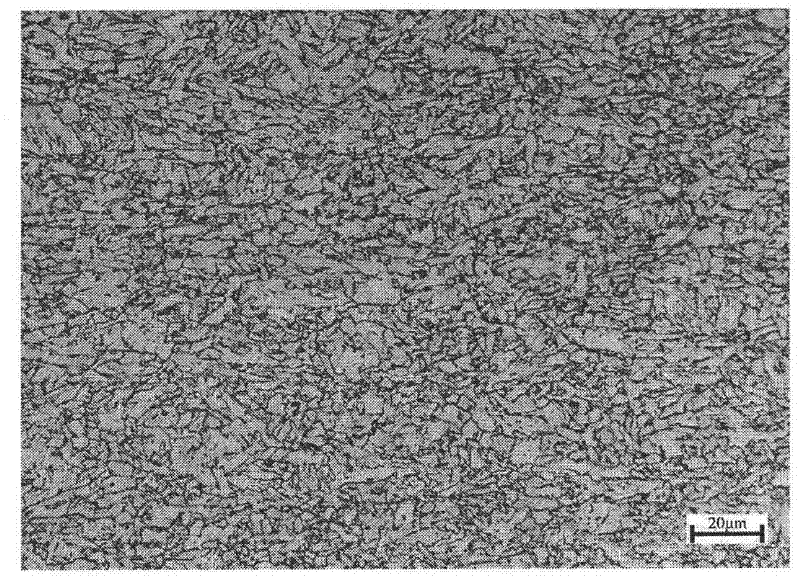

Image

Examples

Embodiment Construction

[0021] The ultra-high-strength cold-rolled steel sheet of the present invention and its manufacturing method will be described below in combination with several specific examples.

[0022] The present invention will be further described below by way of examples.

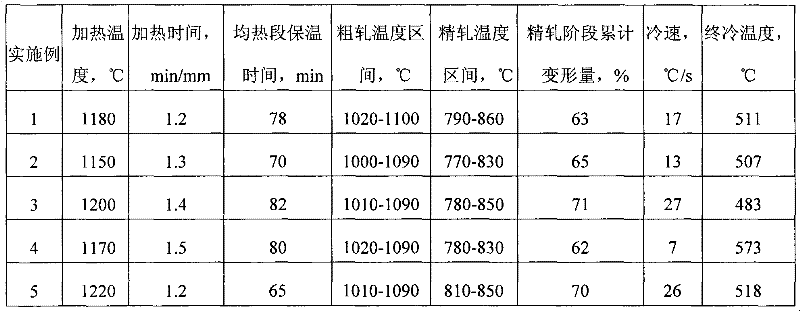

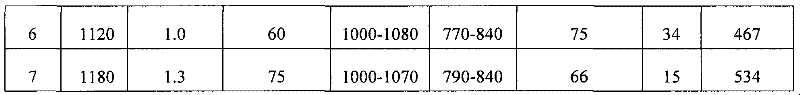

[0023] The chemical composition of the embodiment of the present invention is shown in Table 1; the rolling process of the corresponding embodiment is shown in Table 2; the comprehensive performance is shown in Table 3; the anti-HIC test is shown in Table 4.

[0024] Table 1 The chemical composition wt% of the thick-gauge subsea pipeline steel with excellent low-temperature toughness in the embodiment of the present invention

[0025] Example

[0026] Table 2 The rolling process of the steel for thick gauge submarine pipelines with excellent low temperature toughness in the embodiment of the present invention

[0027]

[0028]

[0029] Table 3 Performance of steel for thick gauge subsea pipeline with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com