Forging process of main stainless-steel pipeline for nuclear power

A main pipe and stainless steel technology, applied in the field of forging, can solve the problems that it is not easy to meet the design size requirements, the heat treatment method cannot be used, and the shape of the forging is complicated, so as to overcome the tendency of hot cracking, ensure the design size requirements, and improve the surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with embodiment:

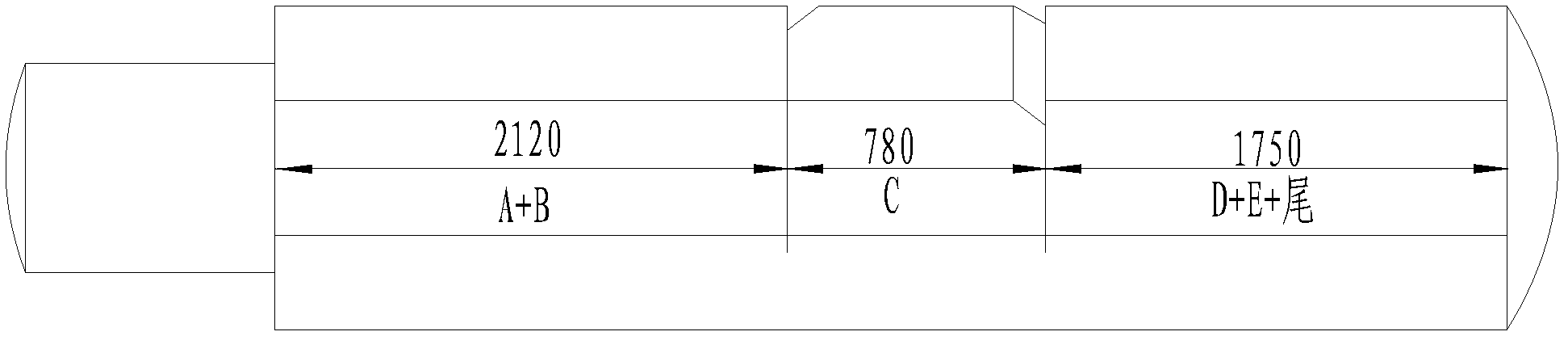

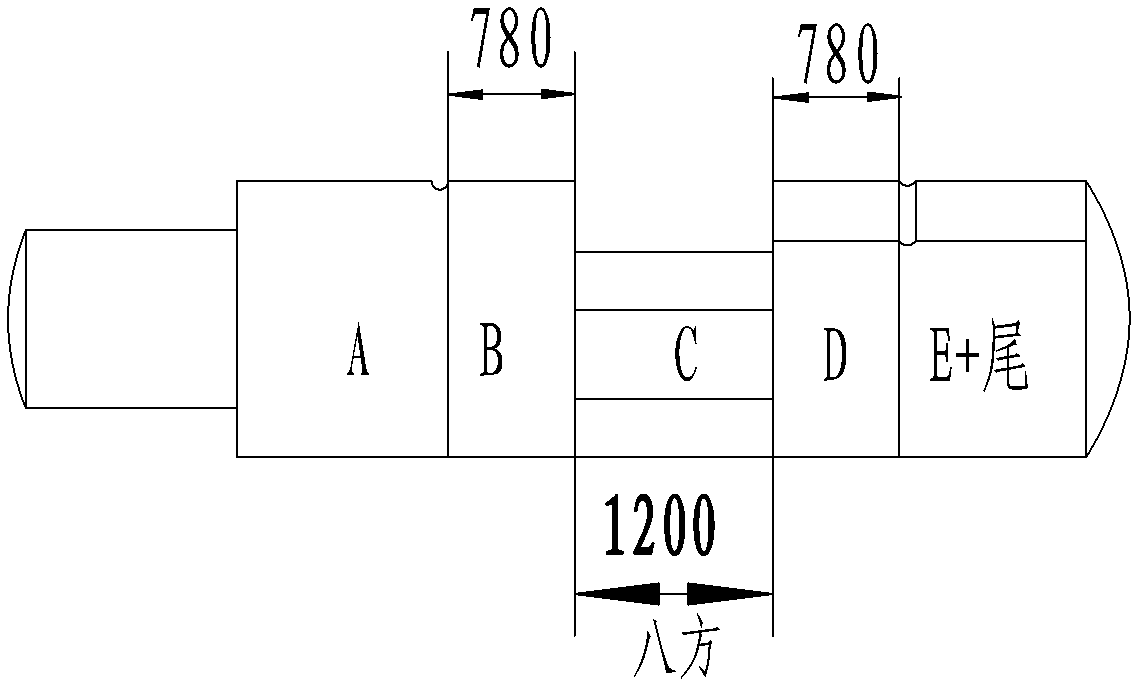

[0064] The invention is a stainless steel nuclear power main pipeline forging process, which adopts 316LN electroslag ingot blank, controls its harmful components S≤0.005% and P≤0.025% during smelting, and heat-cleanes surface cracks in time during the forging process to improve Forging surface quality, its components include hot section L001A, hot section L001B, cold section A, cold section B, cold section C, cold section D, undulating tube I, undulating tube II, undulating tube III, undulating tube IV, undulating tube V has eleven sections. According to different structures and different mechanical performance requirements, the forging process of the above components is divided into hot section L001A, hot section L001B, cold section group, wave tube IIIV group, and wave tube IIIIV group.

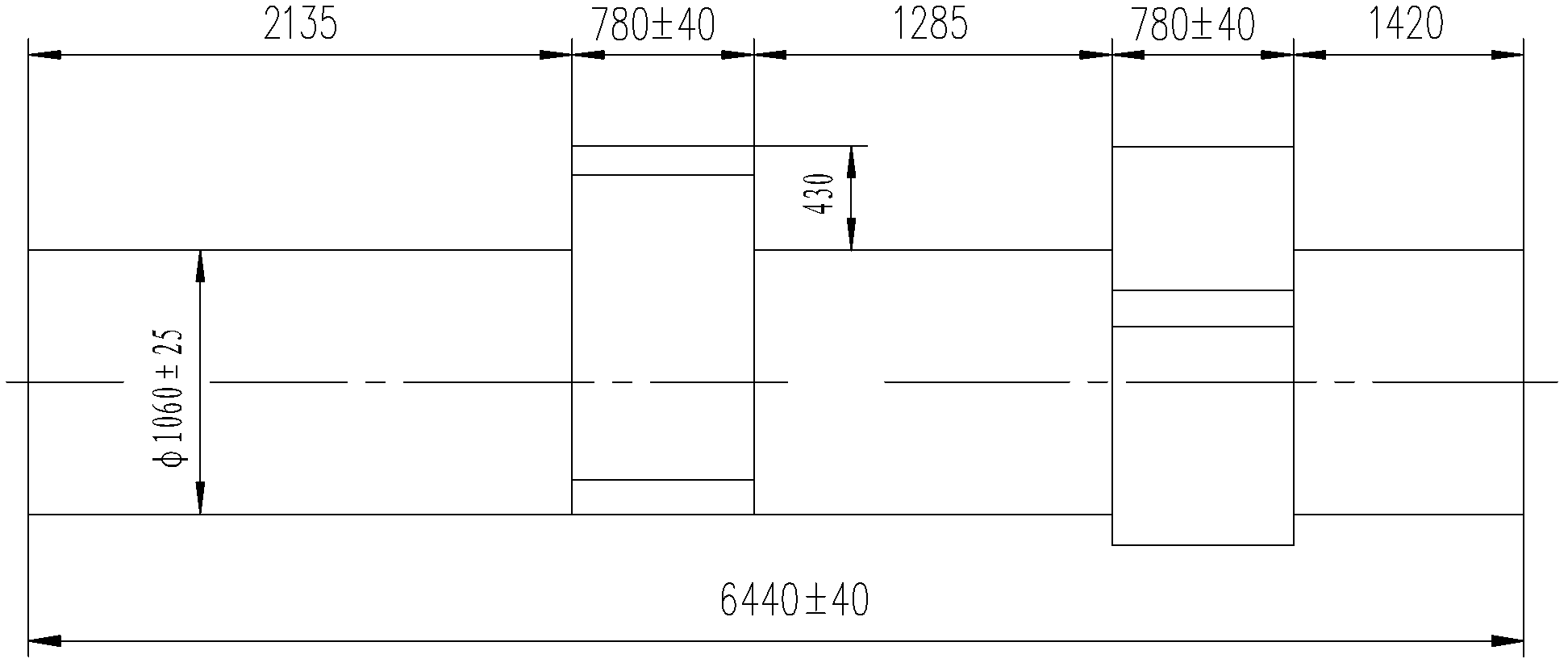

[0065] See figure 1 , figure 2 , image 3 , Figure 4 , showing that the operation steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com