Underground steel gas pipe network pipeline corrosion prediction system

A technology for predicting systems and gas pipes, applied in pipeline systems, weather-resistant/light-resistant/corrosion-resistant, measuring devices, etc., can solve difficult management tasks, complex and diverse buried steel pipeline corrosion data, and difficult to focus on the purpose of pipe sections Issues such as local key supervision and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

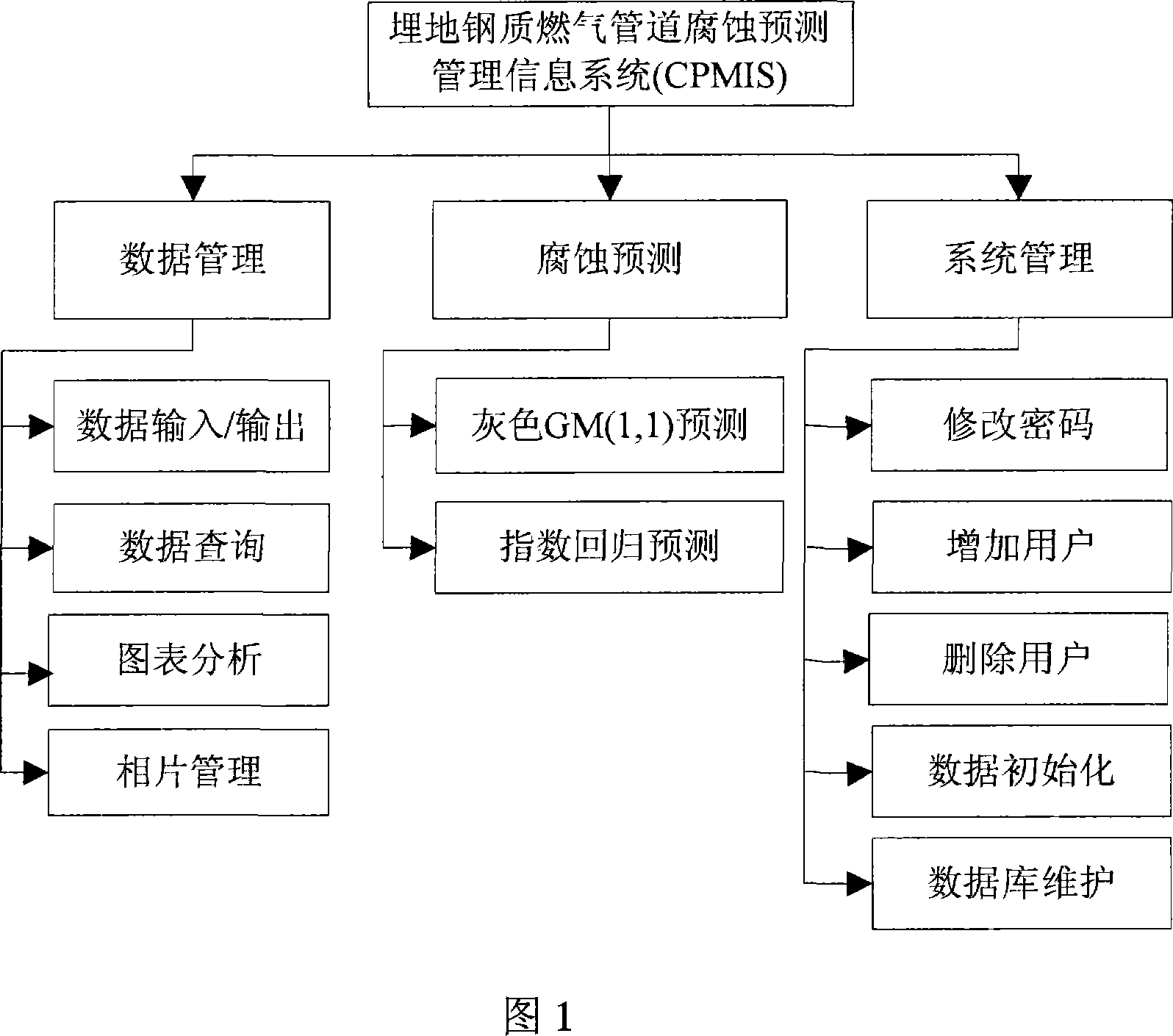

[0015] The module composition diagram of the present invention is shown in Figure 1, including data management, corrosion prediction, and system management. The data management includes data input / output, data query, chart analysis, and photo management. The corrosion prediction includes gray GM (1,1) prediction and exponential regression prediction. The system management includes modifying passwords, adding users, deleting User, data initialization, database maintenance.

[0016] The detailed description of each module is as follows:

[0017] 1. Data management module

[0018] The data management module establishes a database of basic data and corrosion detection data of buried steel gas pipelines, and the administrator can continuously update and improve the database according to actual conditions, thereby realizing dynamic management of pipeline corrosion informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com