Steel pipeline friction-welding device

A pipeline friction and welding equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that friction welding has not yet been applied, and achieve the effects of saving labor costs, stable quality, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

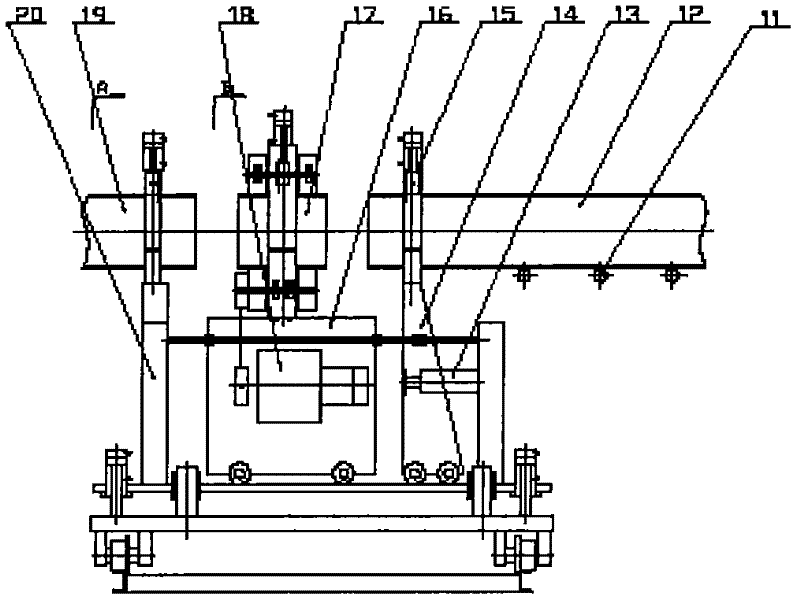

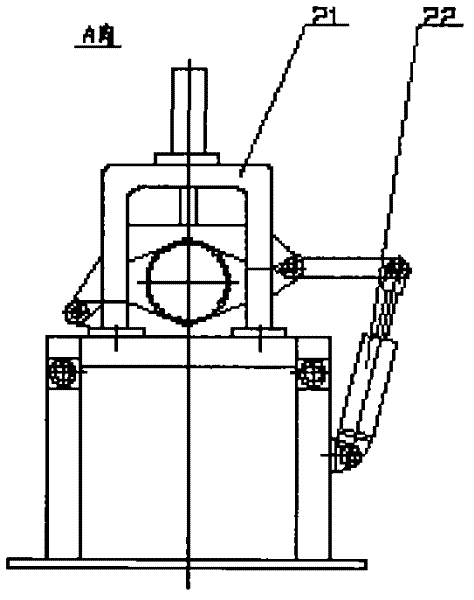

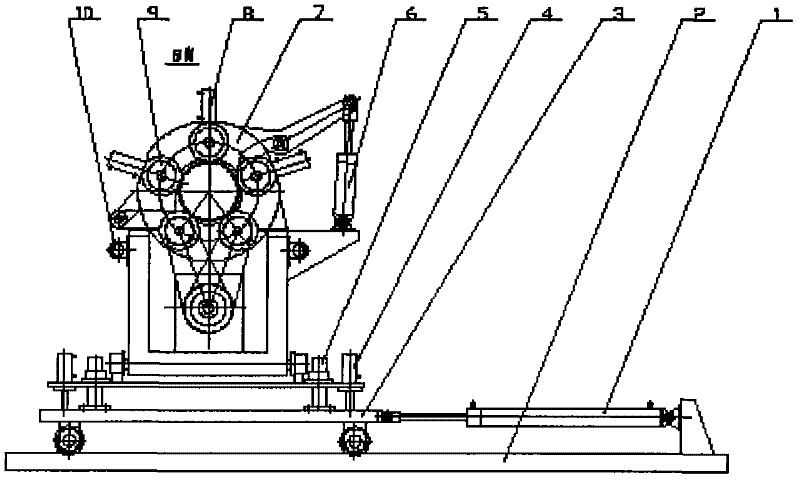

[0019] see Figure 1 ~ Figure 3 , a kind of steel pipe friction welding equipment of the present invention, wherein, the PLC device is respectively connected with the oil cylinder 1, the oil cylinder 4, the oil cylinder 6, the oil cylinder 8, the oil cylinder 13, the oil cylinder 22, and the oil cylinder 15 through the electromagnetic valve, and the oil cylinder 1 is connected with the platform The car 3 is connected, the track 2 is provided under the trolley 3, the oil cylinder 4 is connected with the base plate, the oil cylinder 6 is connected with the clamper 7, the clamper 7 is connected with the clamper base 16, and the clamper 7 is used for clamping The steel pipe section 17, the oil cylinder 8 and the friction wheel 9, the friction wheel 9 includes 5 friction wheels, two of which are fixed friction wheels, which are driven to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com