Analysing method for detection data of pipeline defect leaking magnet

A defect detection and data analysis technology, applied in the field of data analysis, can solve problems such as low efficiency, difficulty in improving the accuracy of pipeline defect quantitative analysis, lack of scientific basis, etc., and achieve the effect of improving analysis efficiency and analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

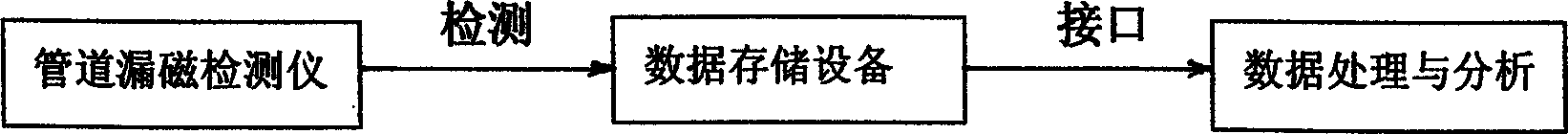

[0017] Such as figure 1 As shown, the pipeline defect magnetic flux leakage detector mainly adopts the principle of magnetic flux leakage nondestructive testing to push it to walk in the steel pipe by the conveying medium, and the magnetic flux leakage signal detected by its own magnetic induction probe is recorded in the memory on the detector. After the inspection is completed, the data exchange is carried out through the interface device, and the data is further analyzed and processed in order to evaluate whether the detected steel pipe has defects and the size of the defects.

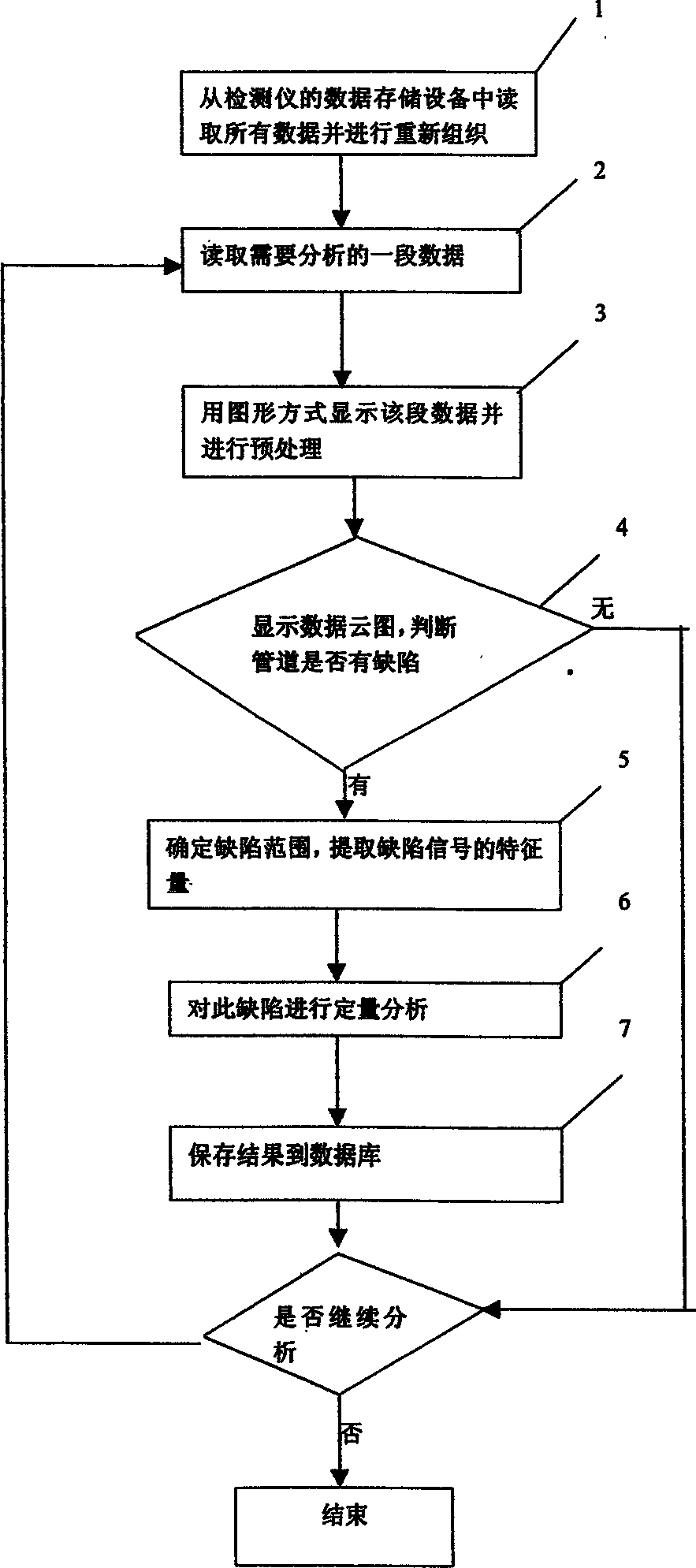

[0018] First of all, due to the huge amount of data collected by the detector, and taking into account the original data of the detection pipeline (such as weld seam information), database technology is used to reorganize the data, such as figure 2 In step 1. The database ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com