Mechanical property measuring device for natural gas hydrates

A natural gas and hydrate technology, which is applied in the direction of applying stable shear force to test the strength of materials and the preparation of test samples, and can solve problems such as threats to the safety of offshore engineering, platform tilt, and uneven bearing capacity of natural gas hydrate formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

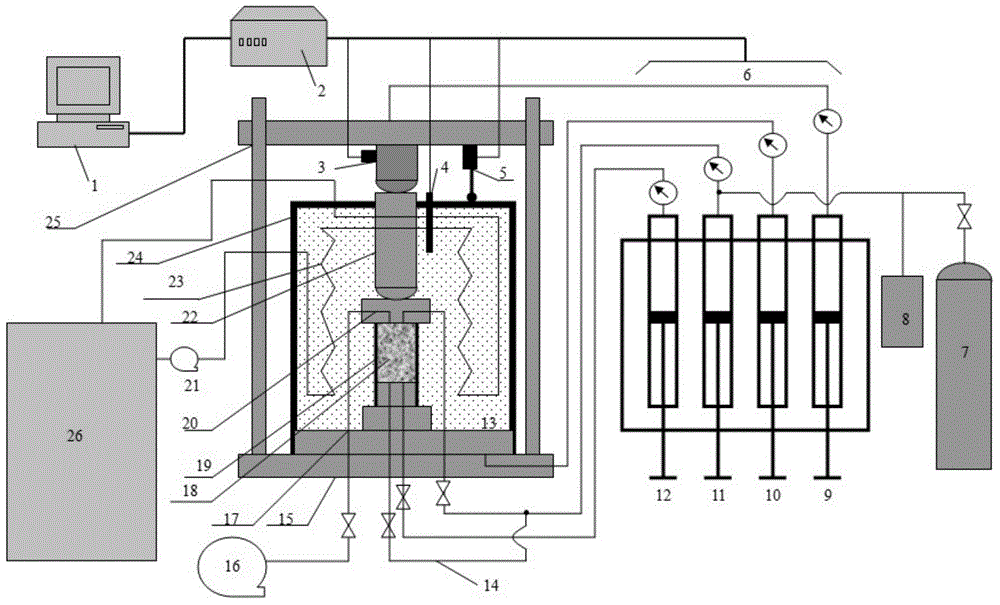

[0020] The embodiment of the natural gas hydrate mechanical property measurement device of the present invention includes a hydrate reaction kettle, a sediment sample preparation and molding system, a constant temperature control system, a natural gas pressurized intake system, a vacuum system and a data acquisition system.

[0021] see figure 1 , figure 1 It is a structural schematic diagram of the device for measuring the mechanical properties of natural gas hydrate in this embodiment.

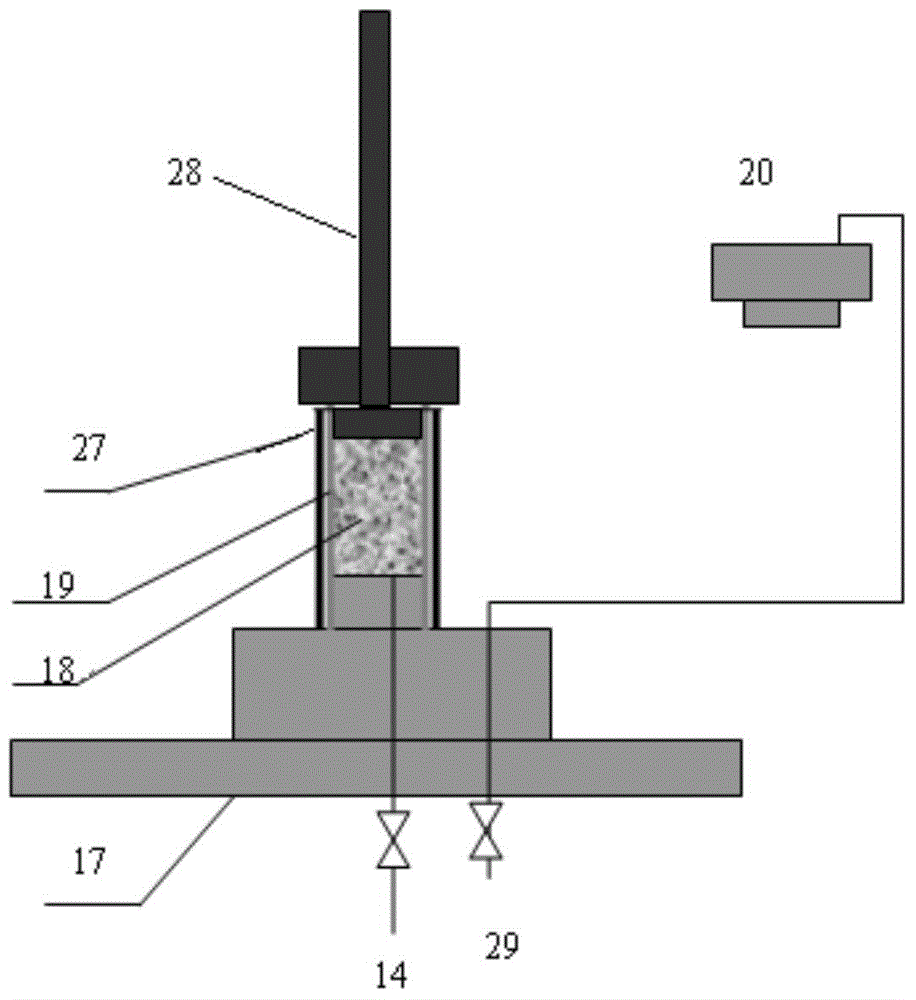

[0022] The above-mentioned hydrate reaction kettle includes a reaction kettle base 17 , a rubber membrane 19 , an end cover 20 , a booster rod 22 , a built-in heat exchanger 23 , a reaction kettle shell 24 and a reaction force frame 25 .

[0023] The reactor shell 24 and the reactor base 17 are connected by bolts and sealed by a sealing ring. The end cap 20 is connected with the reactor base 17 through a spiral stainless steel pipeline. The afterburner rod 22 penetrates from the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com