Stainless steel pipeline welding connection method and center-adjustable connection clamp

A connection fixture and welding connection technology, applied in the direction of welding/welding/cutting items, welding equipment, welding equipment, etc., can solve the problems of difficult welding, difficult to grasp and control, and difficult to control the deformation, so as to ensure the welding operation The effect of reducing the length and joint defect rate and avoiding joint defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

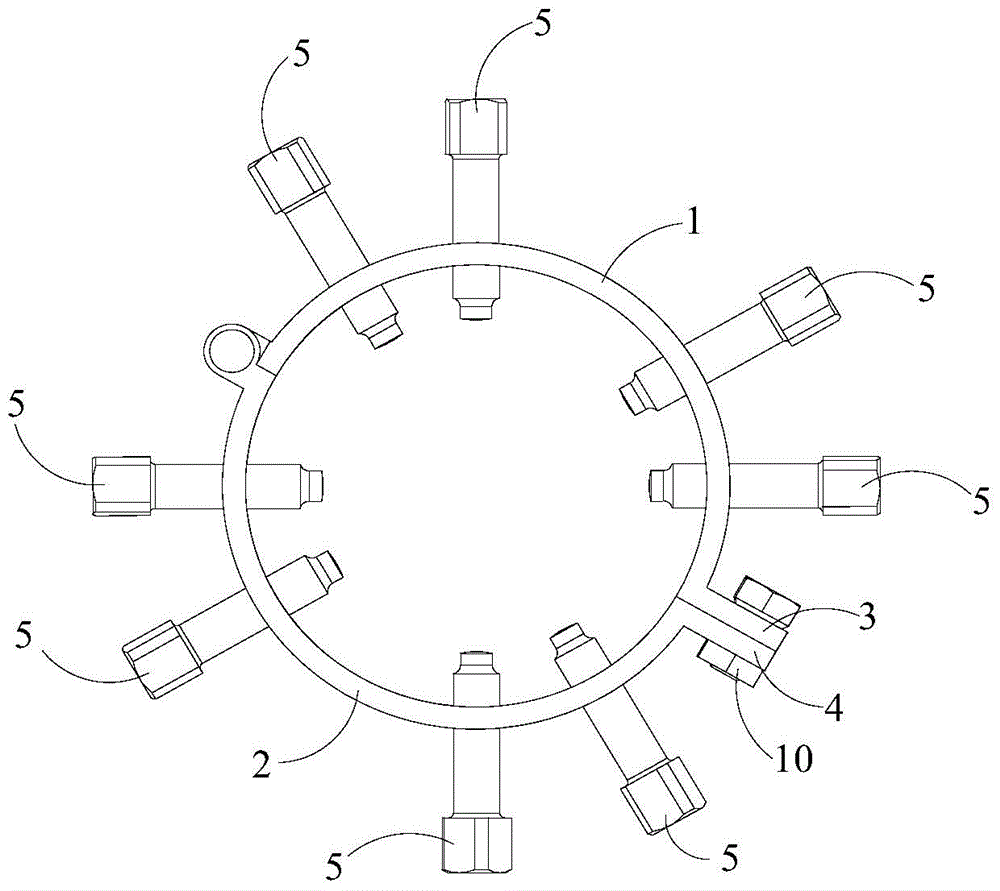

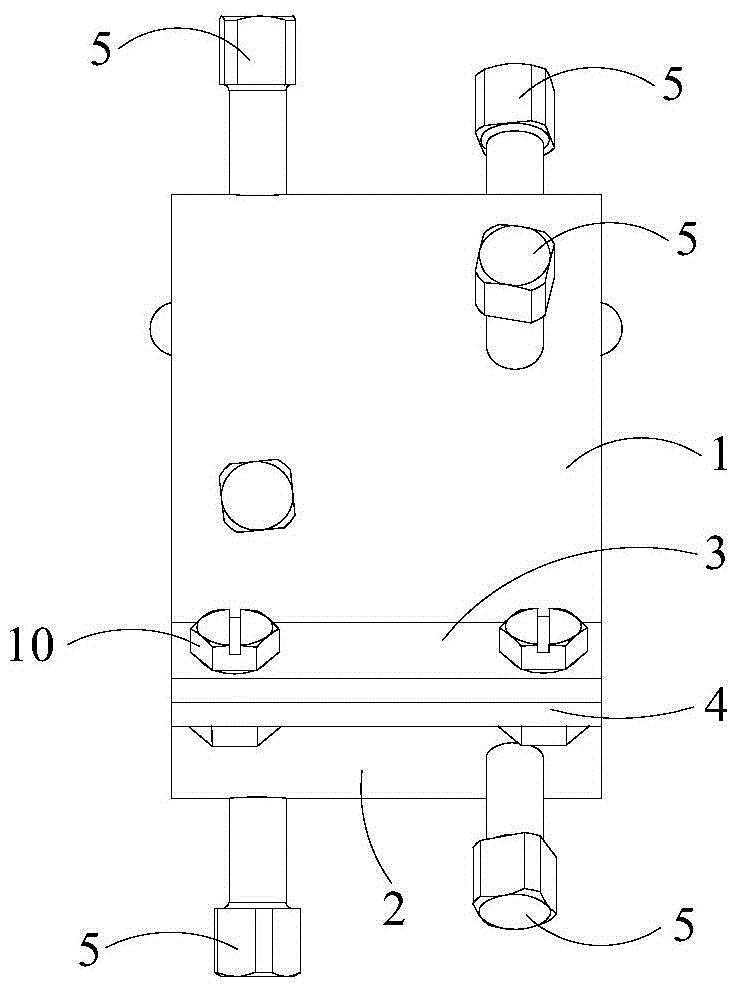

[0047] Such as figure 1 with figure 2 As shown, the first embodiment of the adjustable center connection clamp of the present invention includes a clamp unit. The fixture unit includes an upper half-ring steel plate 1, a lower half-ring steel plate 2 and a plurality of jacking bolts 5. One end of the upper half-ring steel plate 1 and the lower half-ring steel plate 2 are hingedly connected, and the other end is detachably connected together, so that the upper half-ring The steel plate 1 and the lower half-ring steel plate 2 form an accommodating space. A plurality of tightening bolts 5 are respectively installed in the accommodating space formed by the upper half-ring steel plate 1 and the lower half-ring steel plate 2, and the inner ends of the tightening bolts 5 protrude into the accommodating space.

[0048] Further, the other end of the above-mentioned upper half-ring steel plate 1 has an upper pressing plate 3, and the other end of the lower half-ring steel plate 2 has...

Embodiment approach 2

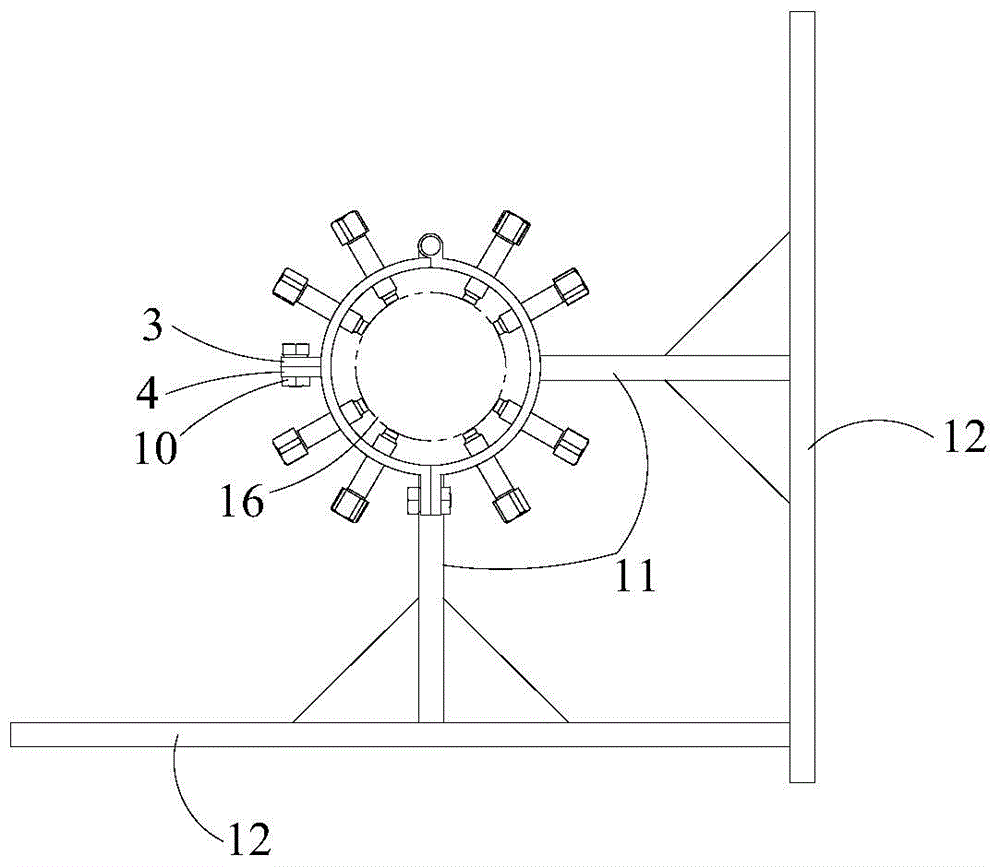

[0054] Such as image 3 , Figure 4 with Figure 5 As shown, the second embodiment of the adjustable center connection clamp of the present invention comprises two independent clamp units. The specific structure of each clamp unit is the same as that of the first embodiment, and will not be repeated here.

[0055] The two fixture units are respectively fixed on two supports 11 by welding, the supports 11 are fixed on the foundation 12, the supports 11 can be temporary supports or formal supports on site, and the base 12 is a large mass object near the site such as a steel plate on a ship or ground. When in use, each clamping bolt 5 on the two fixture units can be screwed in or out, so that two adjacent stainless steel pipes can be positioned in a coaxial state. The function of the support 11 is to limit the relative position between the two adjustable connecting fixture units and prevent them from moving during the welding process. After the stainless steel pipe is welded,...

Embodiment approach 3

[0059] Such as Figure 7 , Figure 8 with Figure 9 As shown, the third embodiment of the adjustable joint clamp of the present invention includes two clamp units. It differs from the second embodiment only in that: the two clamp units are fixedly connected by steel bars 9 . The following takes three steel bars 9 parallel to each other and evenly distributed around the adjustable center connecting fixture as an example to illustrate as follows:

[0060] One end of a steel bar 9 is welded to the upper half-ring steel plate 1 of one of the fixture units, and the other end is welded to the upper half-ring steel plate 1 of the other fixture unit; one end of the other two steel bars 9 is welded to one of them respectively. On the lower half-ring steel plate 2 of the fixture unit, the other end is respectively welded on the lower half-ring steel plate 2 of another fixture unit. The steel bar 9 can be a square steel or a fixture with other cross-sectional shapes. The number of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com