Cold pressure-sensitive adhesive tape for pipeline anticorrosion

A technology of cold-winding pressure-sensitive adhesive tape and pressure-sensitive adhesive layer, which is applied in the direction of pipeline anticorrosion/rust protection, pipeline protection, adhesives, etc., and can solve problems such as complex construction, non-compliance with environmental protection requirements, and environmental and human damage. Convenience, excellent anti-corrosion effect, and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

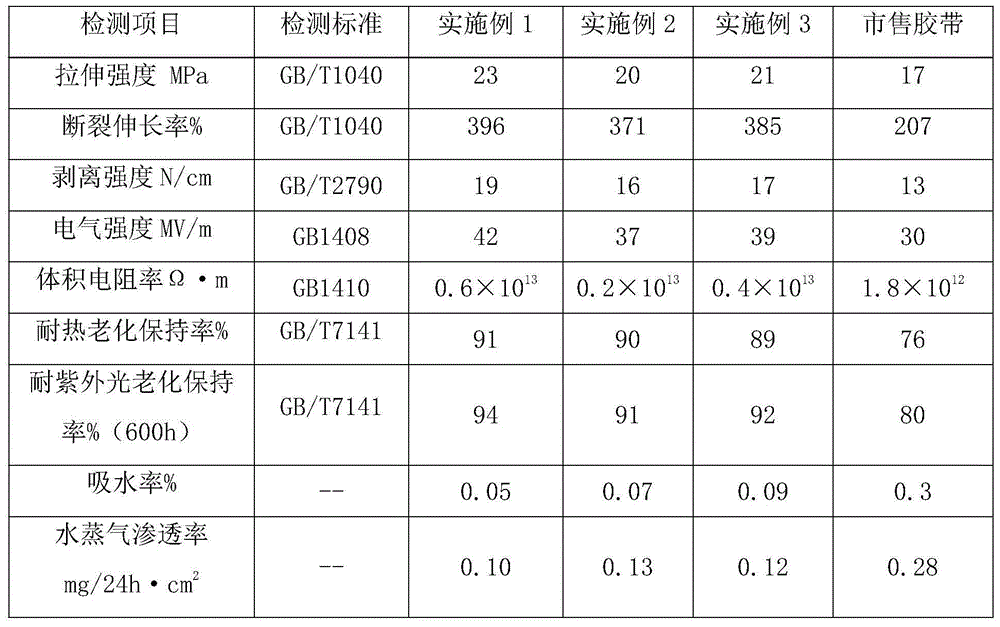

Examples

Embodiment 1

[0021] (1) Weigh each component according to the pressure-sensitive adhesive layer material formula: 50 parts of butyl rubber, 25 parts of polyisobutylene, 17 parts of a mixture of C5 petroleum resin and terpene resin, 4 parts of environmentally friendly aromatic oil, 0.5 parts of antioxidant Composite antioxidant of 246 and zinc dibutyldithiocarbamate, 3.5 parts of light calcium carbonate with an average particle size of 0.1-3μm, put the raw materials of each component into the internal mixer, heat to 130°C, and stir for 20 Minutes, then continue to heat up to 160 ° C, keep warm and continue to stir for 30 minutes to obtain a transparent, uniform viscous liquid;

[0022] (2) putting the transparent and uniform viscous liquid prepared in step (1) into an extruder to melt and extrude it to obtain a pressure-sensitive adhesive;

[0023] (3) Coat the pressure-sensitive adhesive prepared in step (2) on the base film of the high-density polyethylene sheet by an automatic coating ma...

Embodiment 2

[0026] (1) Weigh each component according to the material formula of the pressure-sensitive adhesive layer: 40 parts of butyl rubber, 35 parts of polyisobutylene, 10 parts of rosin glyceride, a mixture of C5 petroleum resin, 8 parts of dibutyl phthalate, 0.5 The composite antioxidant of 246 parts of antioxidant and zinc dibutyldithiocarbamate, 6.5 parts of light calcium carbonate with an average particle size of 0.1 to 3 μm, put the raw materials of each component into the internal mixer, and heat to 130 ℃, stir for 20 minutes, then continue to heat up to 160 ℃, keep warm and continue stirring for 30 minutes to obtain a transparent and uniform viscous liquid;

[0027] (2) putting the transparent and uniform viscous liquid prepared in step (1) into an extruder to melt and extrude it to obtain a pressure-sensitive adhesive;

[0028] (3) Coat the pressure-sensitive adhesive prepared in step (2) on the base film of the high-density polyethylene sheet by an automatic coating machin...

Embodiment 3

[0031] (1) Weigh each component according to the pressure-sensitive adhesive layer material formula: 55 parts of butyl rubber, 20 parts of polyisobutylene, 20 parts of a mixture of C5 petroleum resin and terpene resin, 1 part of environmentally friendly aromatic oil, 0.5 parts of antioxidant Composite antioxidant of 246 and zinc dibutyldithiocarbamate, 3.5 parts of light calcium carbonate with an average particle size of 0.1-3μm, put the raw materials of each component into the internal mixer, heat to 130°C, and stir for 20 Minutes, then continue to heat up to 160 ° C, keep warm and continue to stir for 30 minutes to obtain a transparent, uniform viscous liquid;

[0032] (2) putting the transparent and uniform viscous liquid prepared in step (1) into an extruder to melt and extrude it to obtain a pressure-sensitive adhesive;

[0033] (3) Coat the pressure-sensitive adhesive prepared in step (2) on the base film of the high-density polyethylene sheet by an automatic coating mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com