Helical soldering seam manual checking machine

A technology of spiral welds and scanners, which is applied to instruments, scientific instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., to achieve stable walking and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

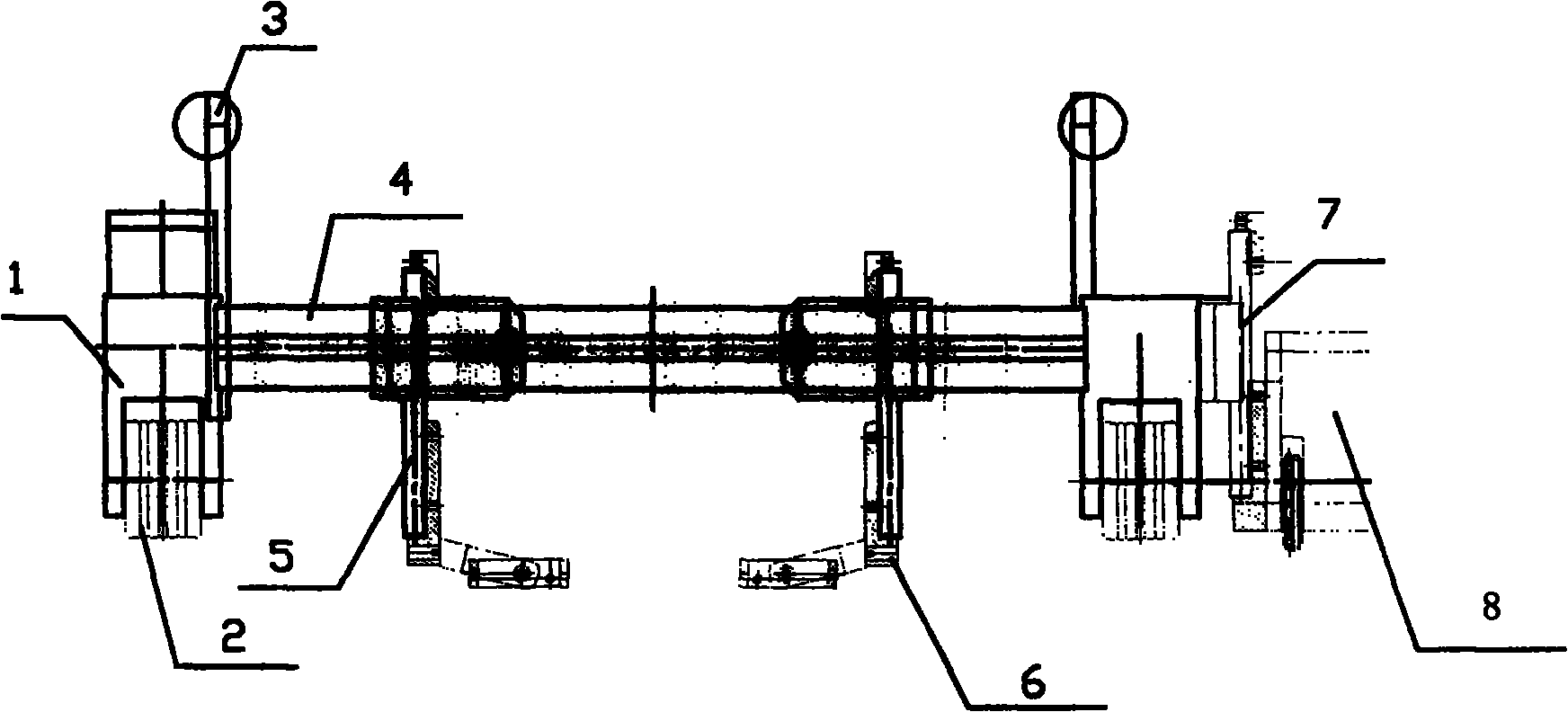

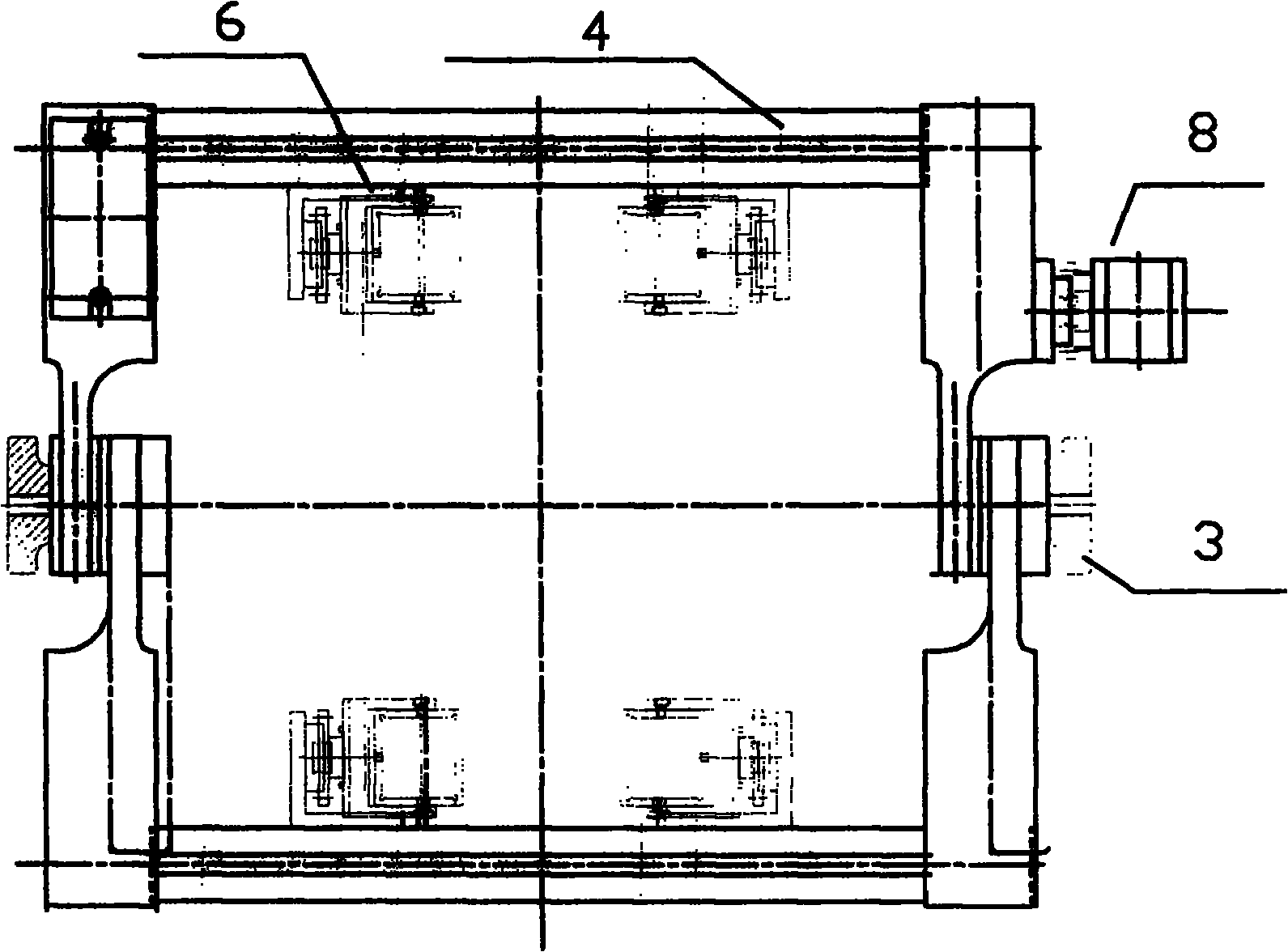

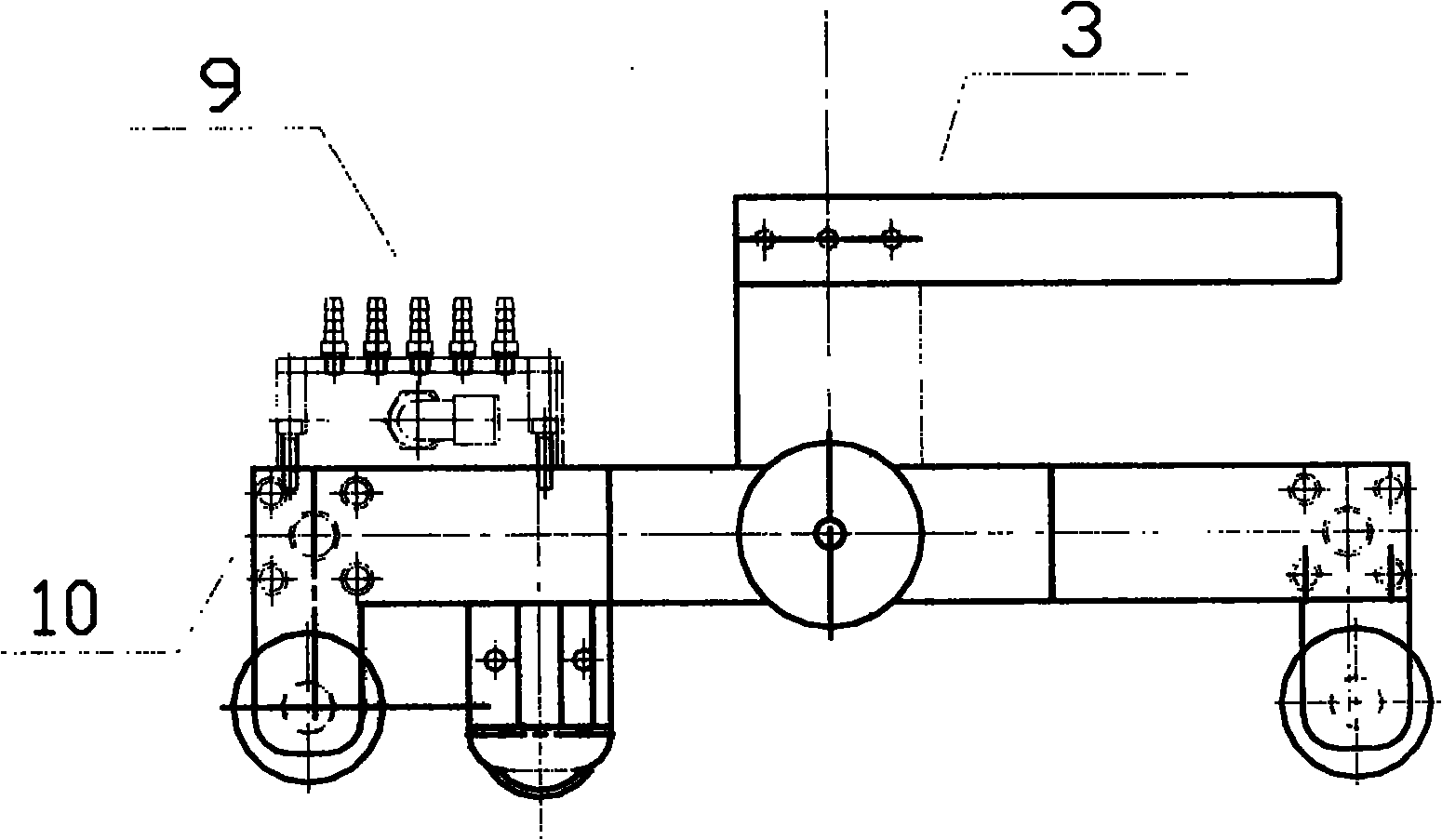

[0056] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental prototype, and its composition is shown in the figure. In this example, the Ominiscan 32 / 128 PR ultrasonic phased array system is used to carry out inspection tests on in-service pipeline welds and base metals. In order to improve the detection efficiency and defect detection rate, a targeted scanning device is required as an auxiliary Inspection equipment, so that the weld flaw detection can complete the single-sided and double-sided inspection of the weld at the same time, and the data collection must be complete.

[0057] The scanner is used to detect the Φ720mm pipeline of the Northeast Pipeline Network. It can not only walk on the steel pipeline, but also take into account the detection of other pipe diameters. The minimum applicable pipe diameter is Φ426mm, and the maximum applicable pipe diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com