Prepn process of outer anticorrosive coating for steel pipe

A technology for anti-corrosion coatings and pipes, applied in coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as poor quality control, long production cycle, and low mechanical strength of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

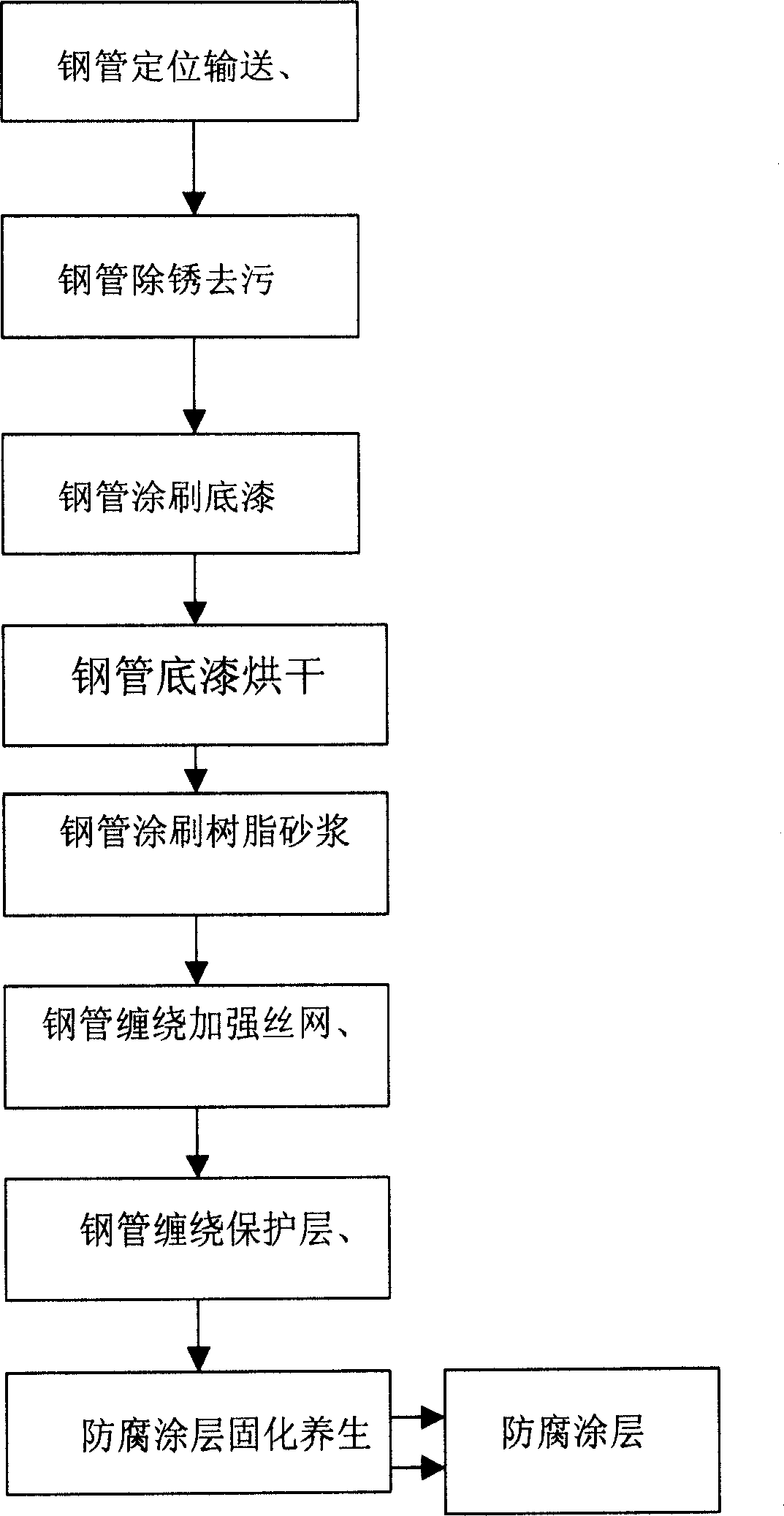

[0025] Describe the present invention in detail below in conjunction with accompanying drawing, figure 1 Clearly shows the process flow of the present invention: a preparation method for the outer anti-corrosion coating of steel pipes, which is composed of a pipe feeding machine, a preheating machine, a shot blasting machine, a mixing machine, a spraying machine, and an extruding glue coating machine. , a winding machine and a mechanized production line consisting of a drying machine, the preparation method of the outer anti-corrosion coating of steel pipes comprises the following steps:

[0026] (1) Steel pipe positioning and conveying

[0027] The anti-corrosion steel pipe is positioned and installed on the mechanical pipe feeder through the bracket, and the pipe feeder drives the pipe to rotate through the transmission mechanism and moves horizontally along the center line of the pipe;

[0028] (2) Steel pipe derusting and decontamination

[0029] The rotating steel pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com