Hot work die steel high in comprehensive performance and preparation method of hot work die steel

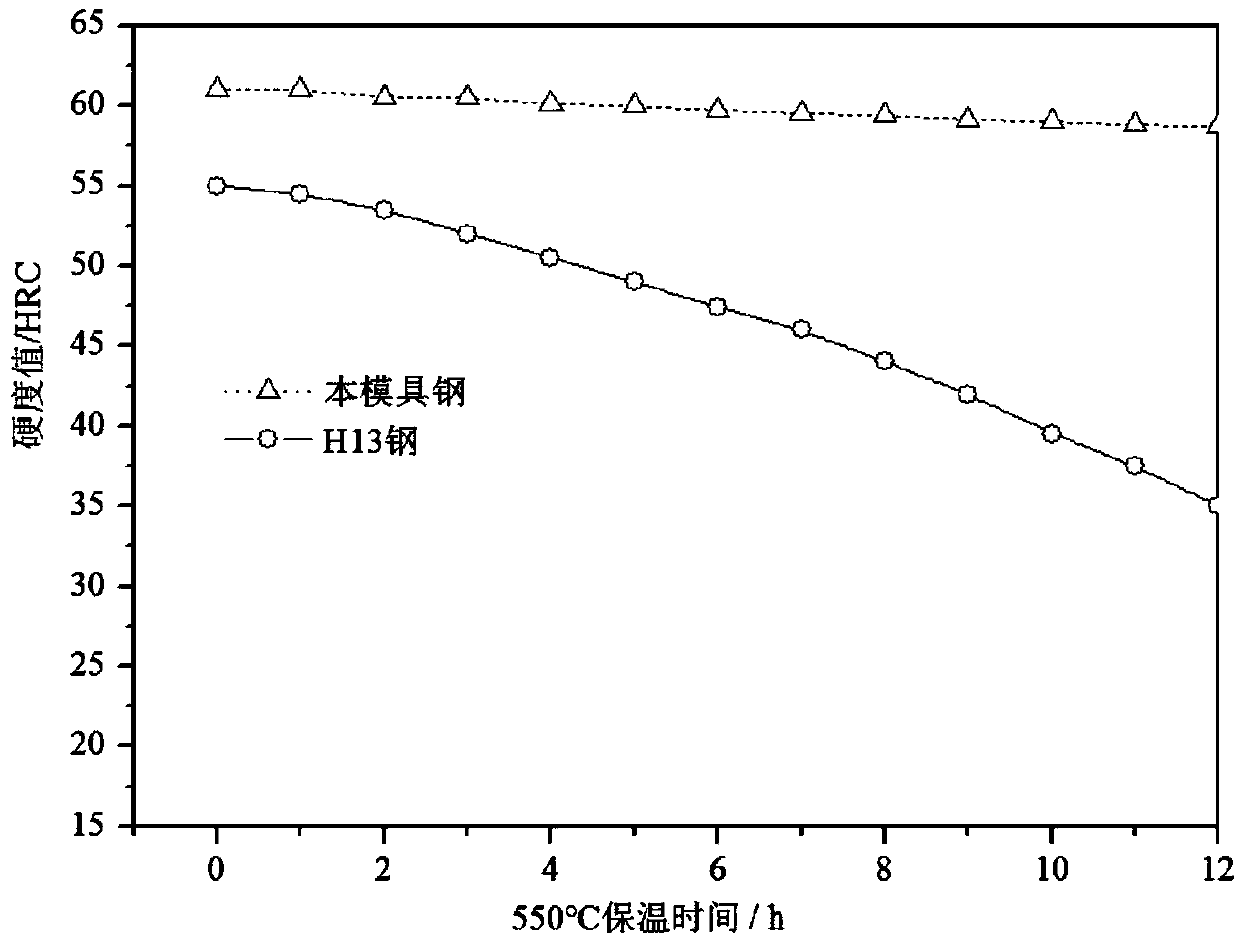

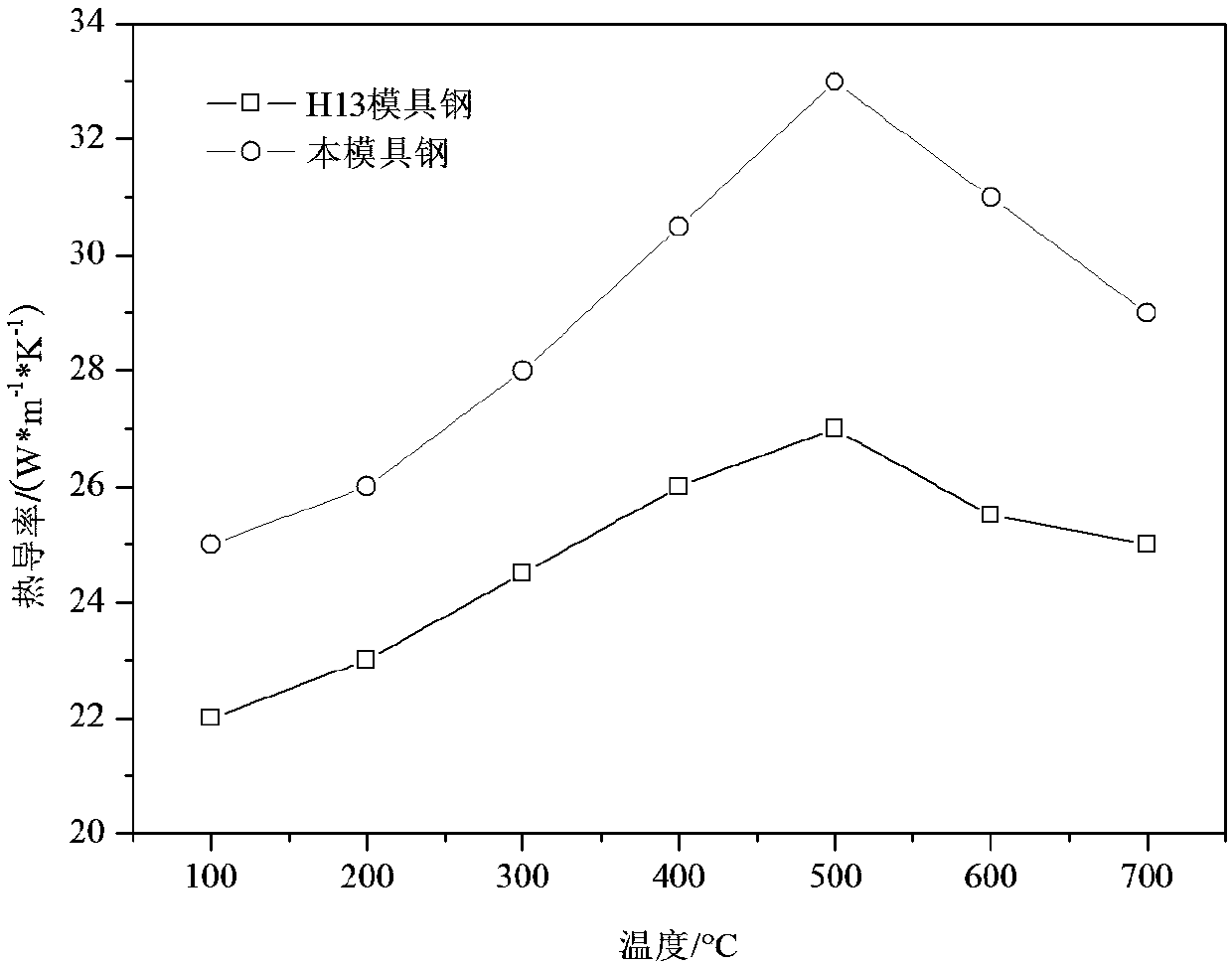

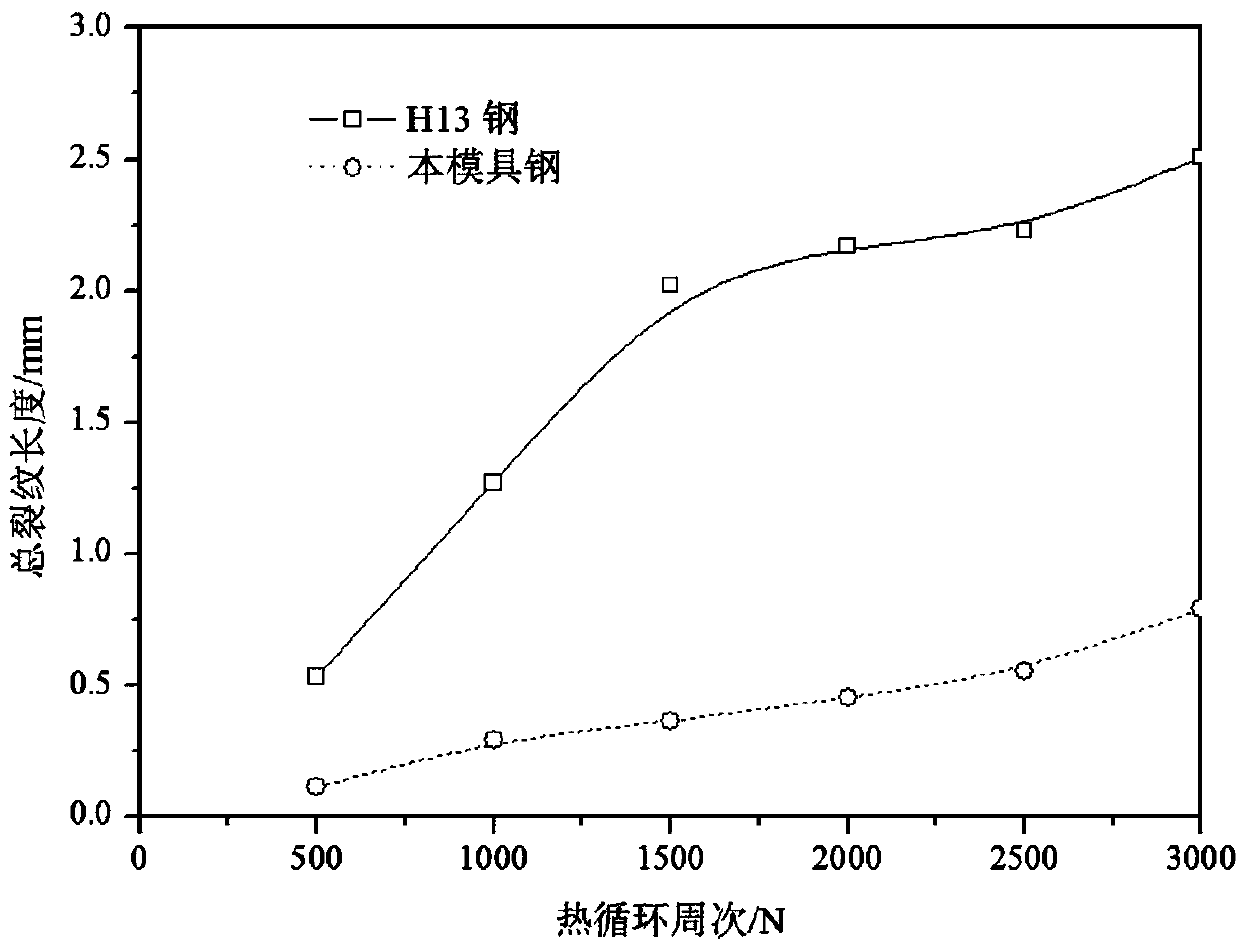

A high-performance technology for hot work die steel, applied in the field of metallurgy technology, can solve the problems of insufficient high temperature strength and low thermal conductivity of hot work die steel, and achieve high red hardness, high high temperature strength, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Taking every 100 tons of steel as an example, the smelting process is as follows:

[0030] 1) Electric arc furnace melting

[0031] Use electric arc furnace to melt metal material and steel scrap and roughly adjust the composition. Add about 2-3% of CaO and about 1% of FeO for slagging, control the basicity between 5-7, carry out dephosphorization, control the steel P≤30ppm in the furnace; add the master alloy additive ( Iron-silicon alloy, ferromanganese alloy, Fe-Cr alloy, Fe-Mo alloy, Fe-V alloy, etc.), tapping temperature 1650-1700°C, C≤0.35% when tapping, adding aluminum with molten steel (per ton of molten steel Add 1Kg), pre-melted slag 200~300kg, leaving steel without slag and tapping;

[0032] 2) Refining in LF furnace: adjust alloy composition and deoxidize through LF refining furnace (vacuum carbon deoxidation, if Al is used for deoxidation, it is easy to cause alumina inclusion), desulfurization, control S≤30ppm; w p H -6 ,w O -6The liquid steel can effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com