Production technique method of double-liquid bimetal composite casting hammer type hammerhead

A dual-liquid bimetal and composite casting technology, which is applied in the field of production technology of the dual-liquid bimetal composite casting hammer head, can solve the problems of broken shank and poor wear resistance of the hammer head, and achieves optimized performance and high durability. The effect of abrasiveness and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

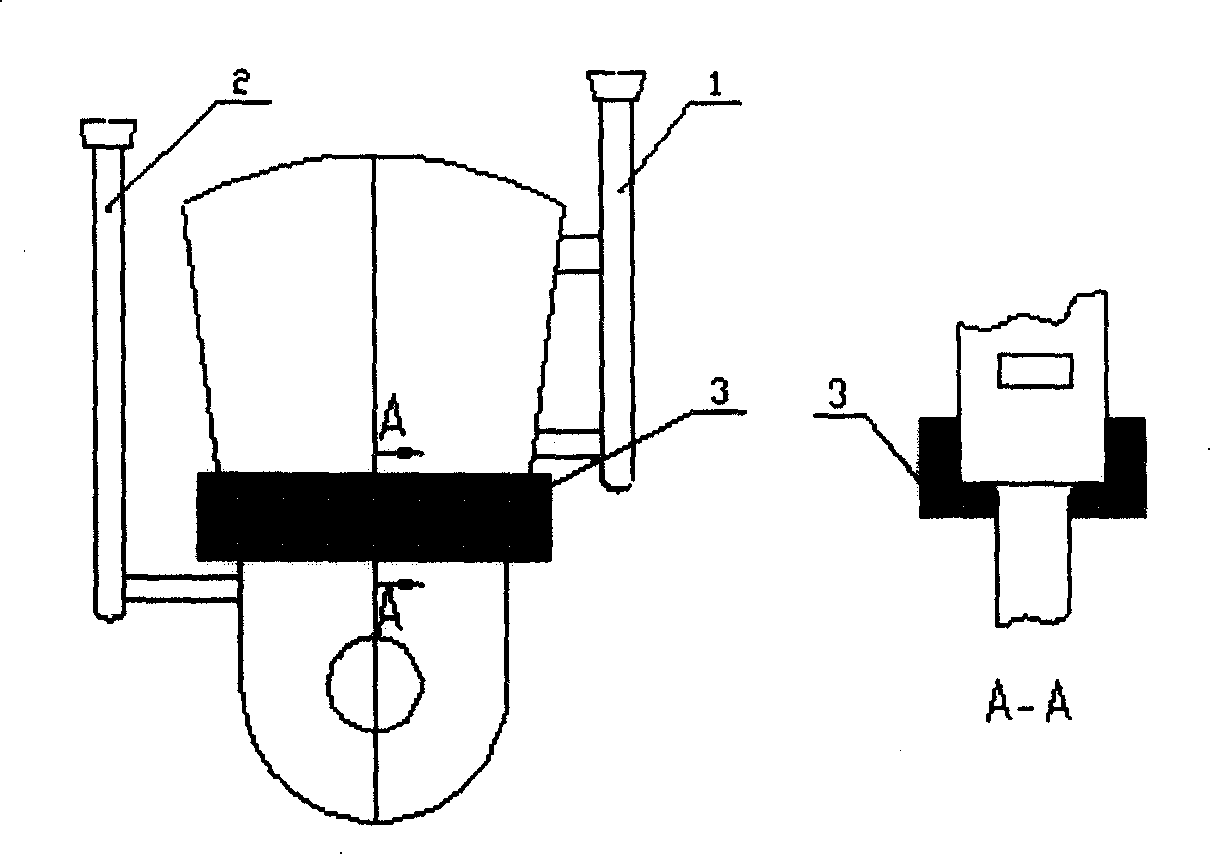

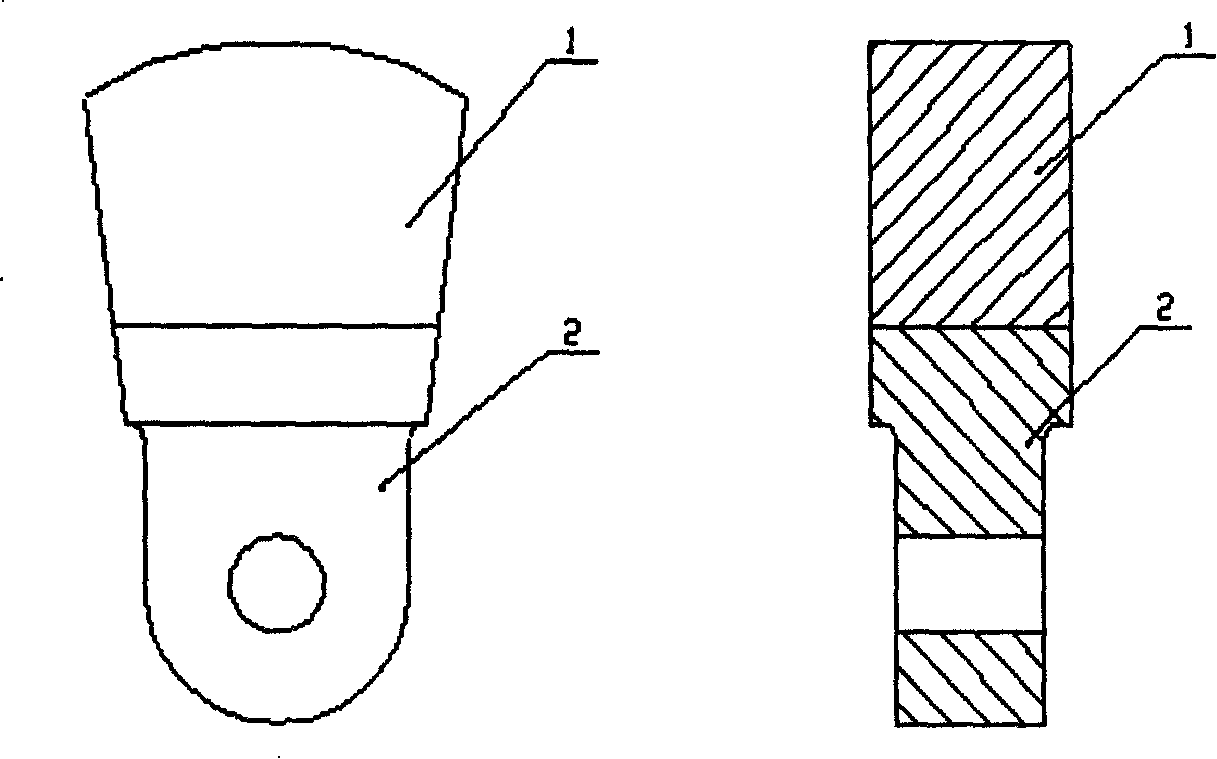

[0010] Two pouring systems are used. First pour low-alloy steel or ordinary cast steel at the cast steel gate. When the molten steel reaches the composite interface or a little below, according to the size of the casting, the interval is 3-120 seconds. After that, the high-chromium Pour high-chromium cast iron or high-alloy steel into the cast iron gate, and place chilling material at the cast steel at the steel connection part to ensure that the crystallization interface and the matrix have a certain temperature gradient, a certain thickness and a complete bonding interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com