Automatic efficient motor stamped steel device and punching technology thereof

A motor punching, high-efficiency technology, applied in feeding devices, positioning devices, storage devices, etc., can solve the problems of hidden safety hazards in sorting and picking up, and labor intensity is not reduced, so as to reduce processes and reduce scrap , The effect of punching flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

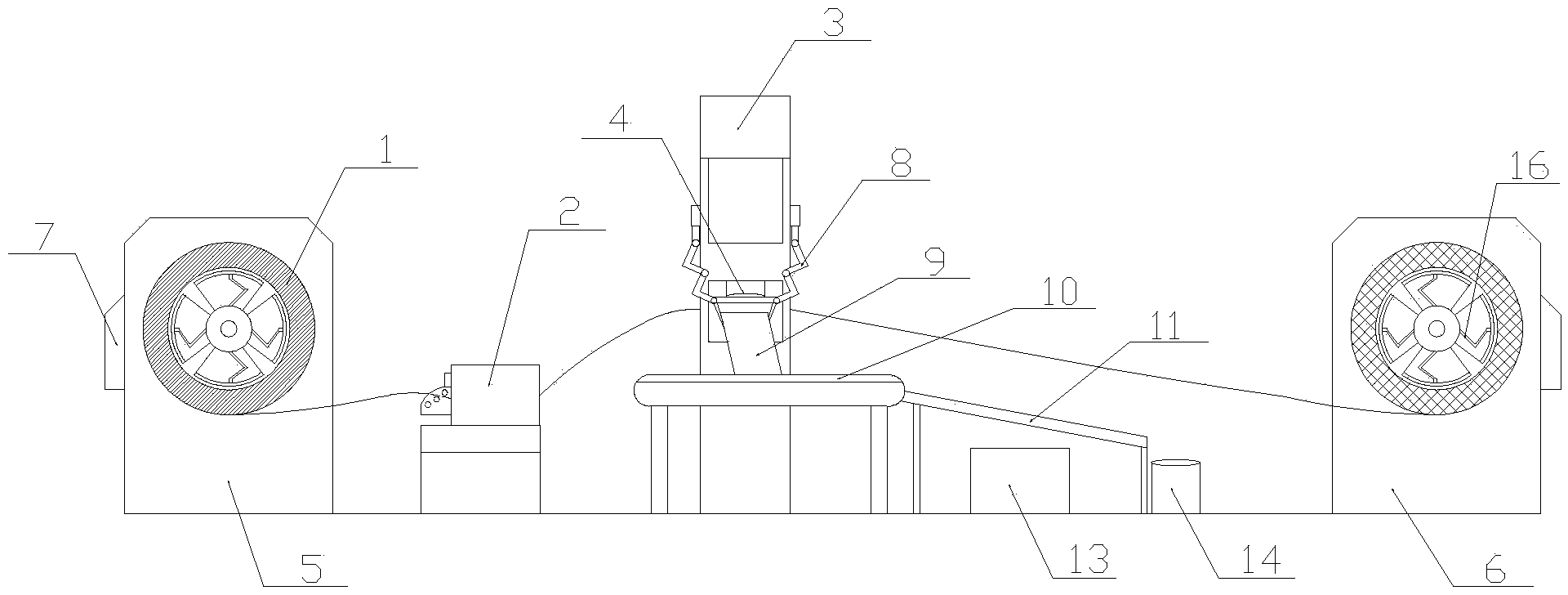

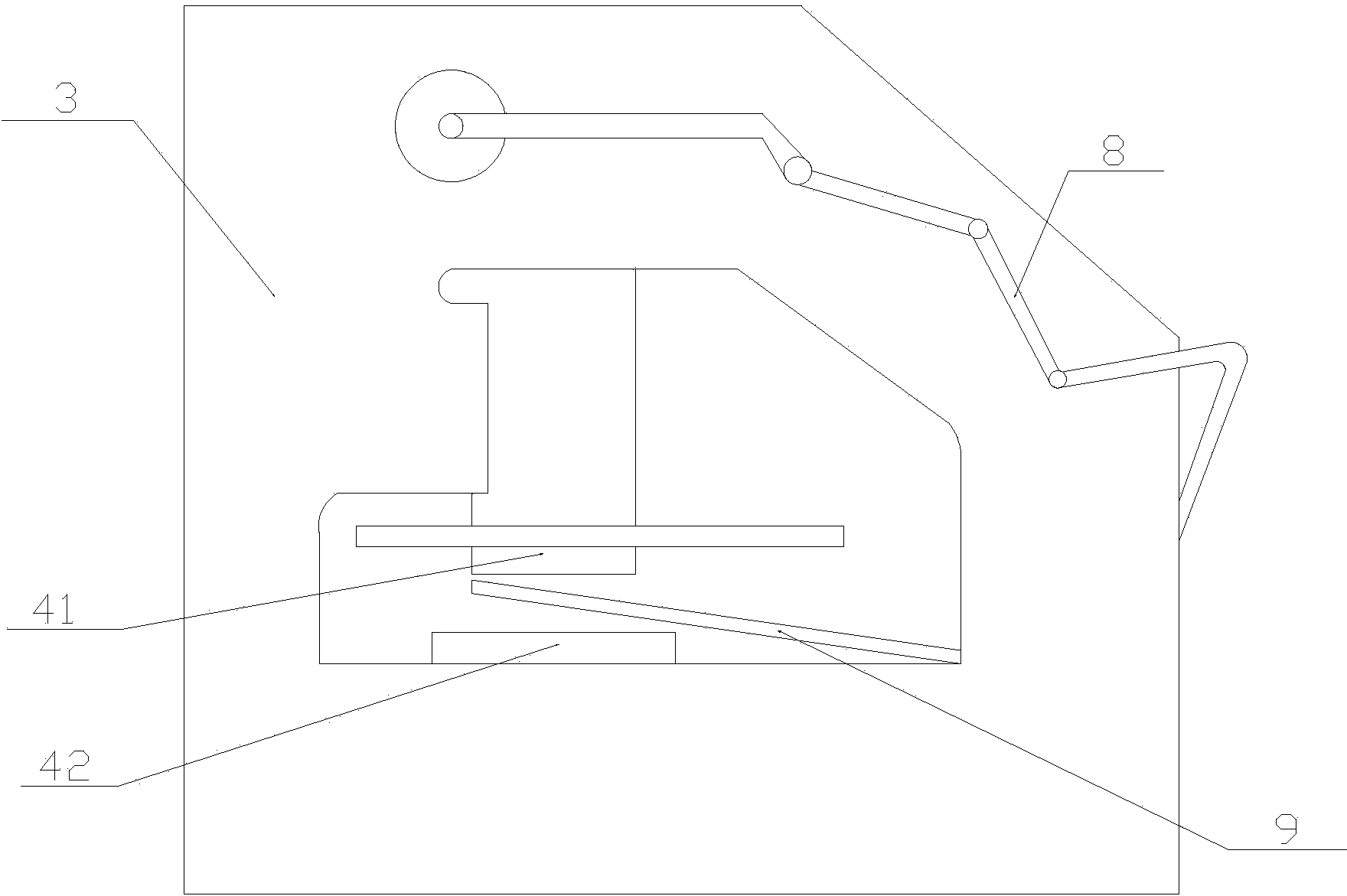

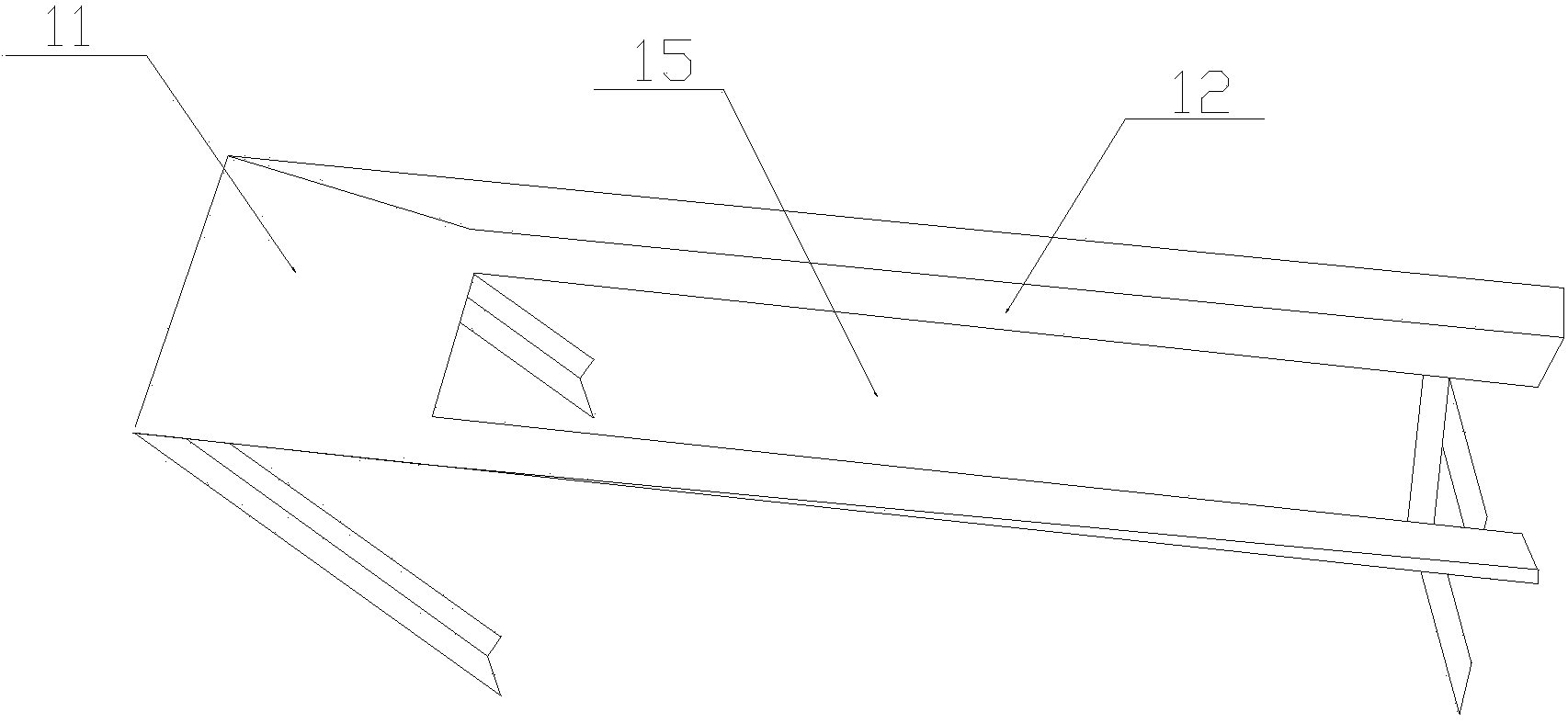

[0031] Such as Figure 1~3 As shown, an automatic high-efficiency motor punching device assembly includes a silicon steel sheet coil 1, a yaw feeding device 2, a special punch press 3, a one-time finished product punching die 4, and a numerically controlled automatic feeding device 5 and waste material The recovery device 6, the silicon steel sheet coil 1 is set on the automatic unwinding device 5, the right side of the automatic unwinding device 5 is provided with a yaw feeding device 2, the right side of the yaw feeding device 2 is provided with a special punch 3, the special punch The right side of 3 is provided with a waste recycling device 6; the special punch 3 is provided with a curved arm structure 8 that drives the punch to move up and down, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com