Welding method and silver based metal for hard-alloy heavy type cutting tools

A technology of hard alloy blades and hard alloys, which is applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of reduced life, product quality, and influence on welding strength, so as to avoid welding cracks, Ensure welding quality and prevent surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Steel substrate size: 152×45×21mm, carbide blade size: 152×21×11mm.

[0031] Silver-based solder consists of the following components by weight percentage: Ag 40%, Cu 30%, Zn 25%, Sn2%, Ni2%.

[0032] The welding temperature is 640°C, the heating rate is 1 degree / second, and the temperature is kept for 3 minutes. Then, the temperature was lowered to 300° C., the cooling rate was 3 degrees per second, and the temperature was kept for 60 minutes. Then, the power was turned off and the furnace was cooled to room temperature.

[0033] Test results: The welding area is completely filled without voids or cavities; the solder is evenly distributed, and no fast and strong impurities are observed; the silver-based solder, steel substrate, and carbide blade are all in a good bonded state, and no gaps are found .

Embodiment 2

[0035] Steel substrate size: 210×45×21mm, carbide blade size: 210×21×11mm.

[0036] Silver-based solder consists of the following components by weight percentage: Ag45%, Cu25%, Zn25%, Sn 2%, Ni2%.

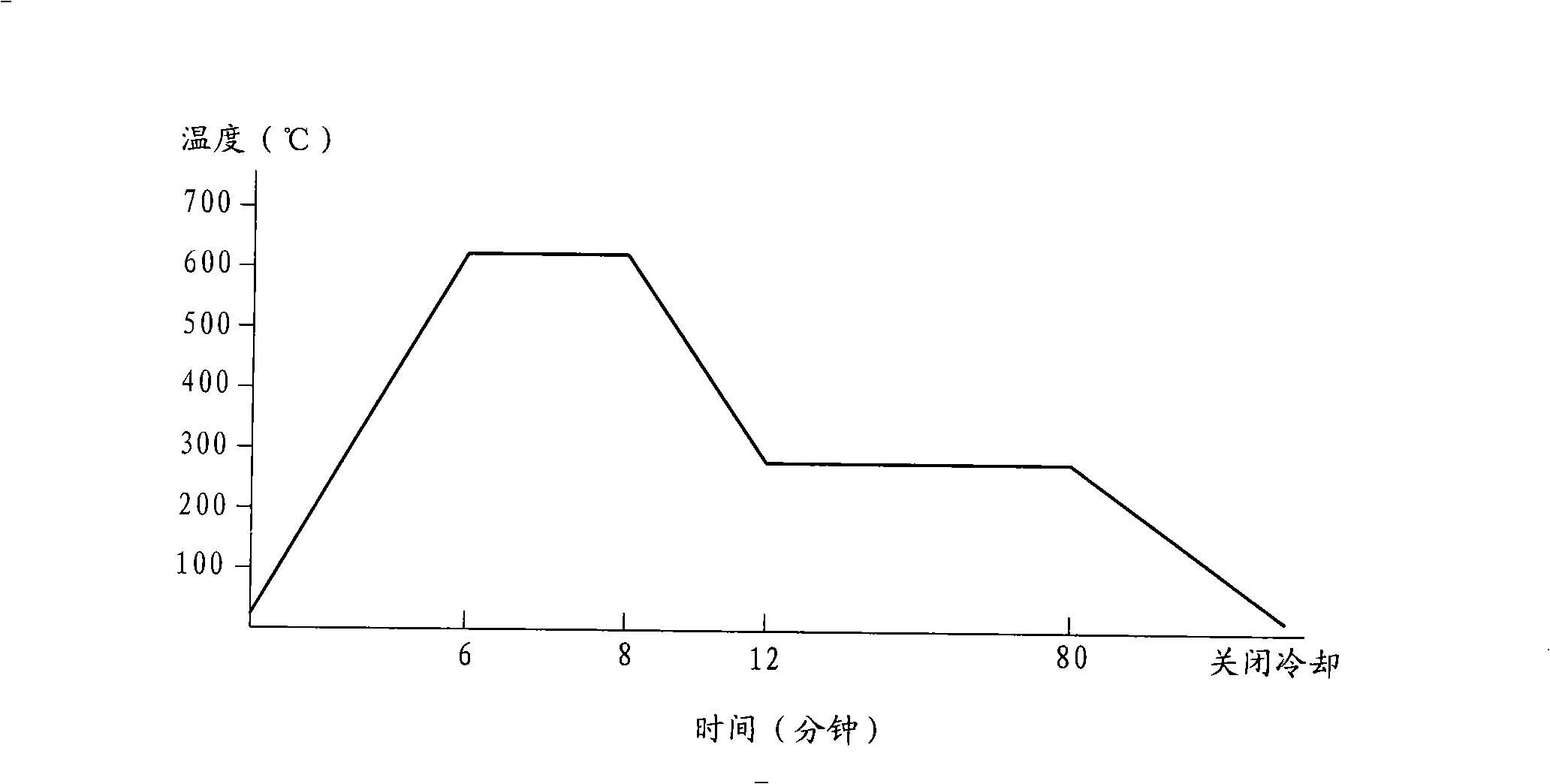

[0037]The welding temperature is 620° C., the heating rate is 3 degrees per second, and the temperature is kept for 2 minutes. Then, lower the temperature to 290° C. at a cooling rate of 6 degrees per second, keep the temperature for 80 minutes, turn off the power and cool to room temperature with the furnace.

[0038] Test results: The welding area is completely filled without voids or cavities; the solder is evenly distributed, and no fast and strong impurities are observed; the silver-based solder, steel substrate, and carbide blade are all in a good bonded state, and no gaps are found .

Embodiment 3

[0040] Steel substrate size: 210×45×21mm, carbide blade size: 210×21×11mm.

[0041] Silver-based solder consists of the following components by weight percentage: Ag 50%, Cu 20%, Zn 25%, Sn 2%, Ni 2%.

[0042] The welding temperature is 600° C., the heating rate is 5 degrees per second, and the temperature is kept for 3 minutes. Then, the temperature was lowered to 280° C., the cooling rate was 8 degrees per second, and the temperature was kept for 100 minutes. Then, the power was turned off and the furnace was cooled to room temperature.

[0043] Test results: The welding area is completely filled without voids or cavities; the solder is evenly distributed, and no fast and strong impurities are observed; the silver-based solder, steel substrate, and carbide blade are all in a good bonded state, and no gaps are found .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com