Manufacturing method of low-yield-ratio carbon-manganese low-temperature steel

A manufacturing method and low yield-strength ratio technology, applied in the field of low-alloy structural steel manufacturing, can solve the problems of increasing the tendency of bainite transformation in the HAZ area, the influence of low temperature performance, etc., to achieve simple composition design and process route, high toughness welding performance, the effect of excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment further illustrate.

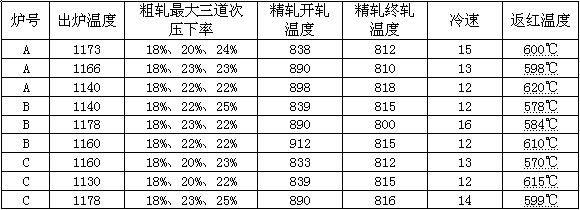

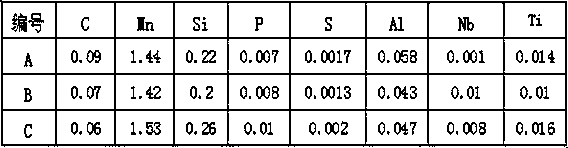

[0027] The embodiment is carbon-manganese low-temperature steel for liquefied petroleum gas ships with low yield ratio, which is divided into three groups (furnace numbers) of ABC. The chemical composition of the steel is shown in Table 1.

[0028] The manufacturing method includes the following steps:

[0029](1) Smelting and casting: Converter or electric furnace is used for smelting, and continuous casting is used for casting; the molten iron is pretreated and desulfurized, and the converter strengthens the end point control. When tapping, [C]≤0.005, [P]≤0.005, and the whole process of argon blowing is turned on when tapping , Use slag blocking rod or slag blocking ball to block slag. After the molten steel arrives in the LF refining furnace, it is heated up and white slag is produced. It is required to form slag quickly, keep the white slag time ≥ 15 minutes, and the total refining time in the station ≥ 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com