High-temperature splicing and quenching forming process and device of ultrahigh-strength steel

A technology of ultra-high-strength steel and forming technology, which is applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problems of mold surface wear, steel plate formability decline, laser tailor welding equipment, etc., to improve production efficiency, The effect of reducing the production process and making the product quality easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

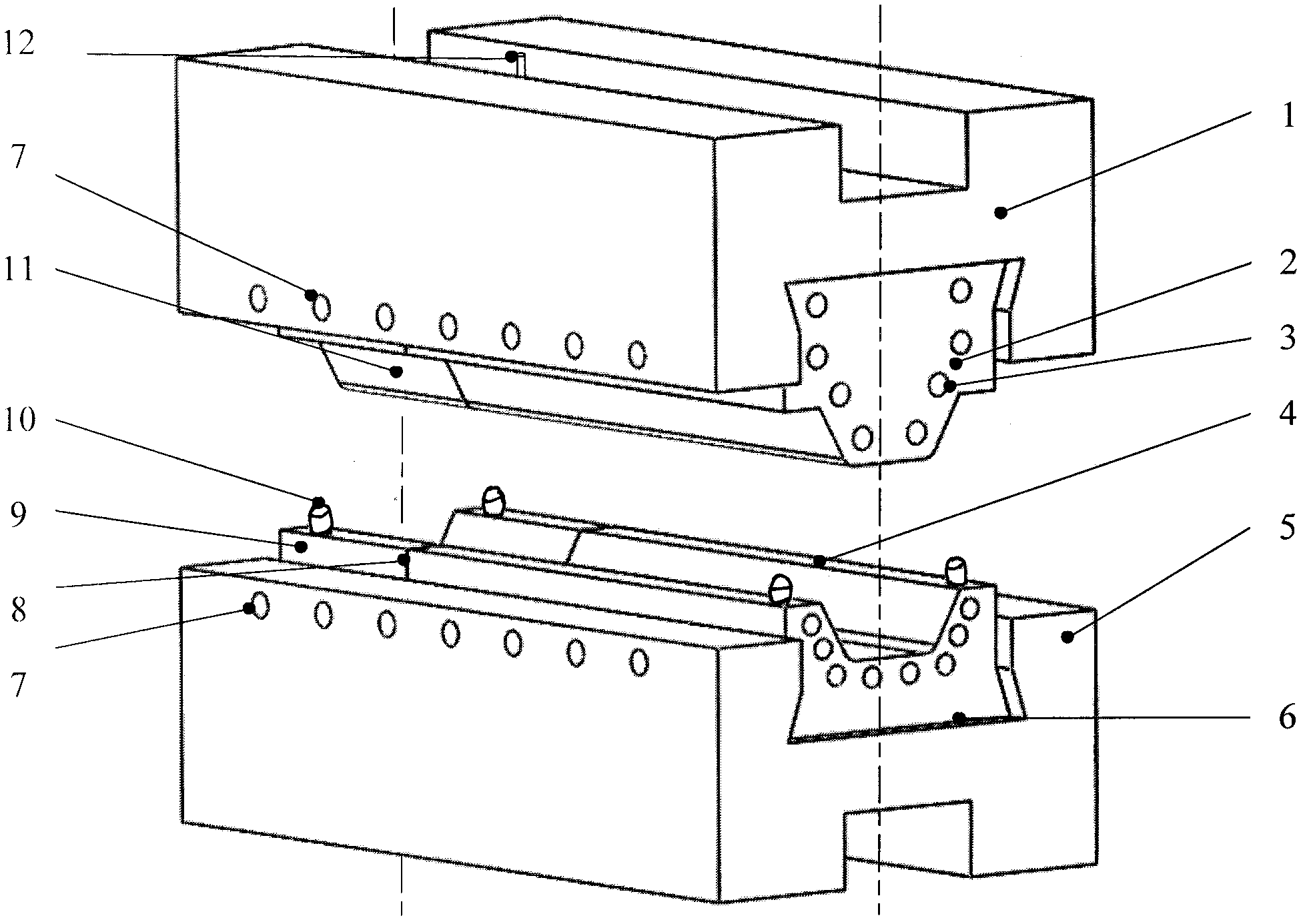

[0057] The present invention will be further described below with reference to the drawings and examples.

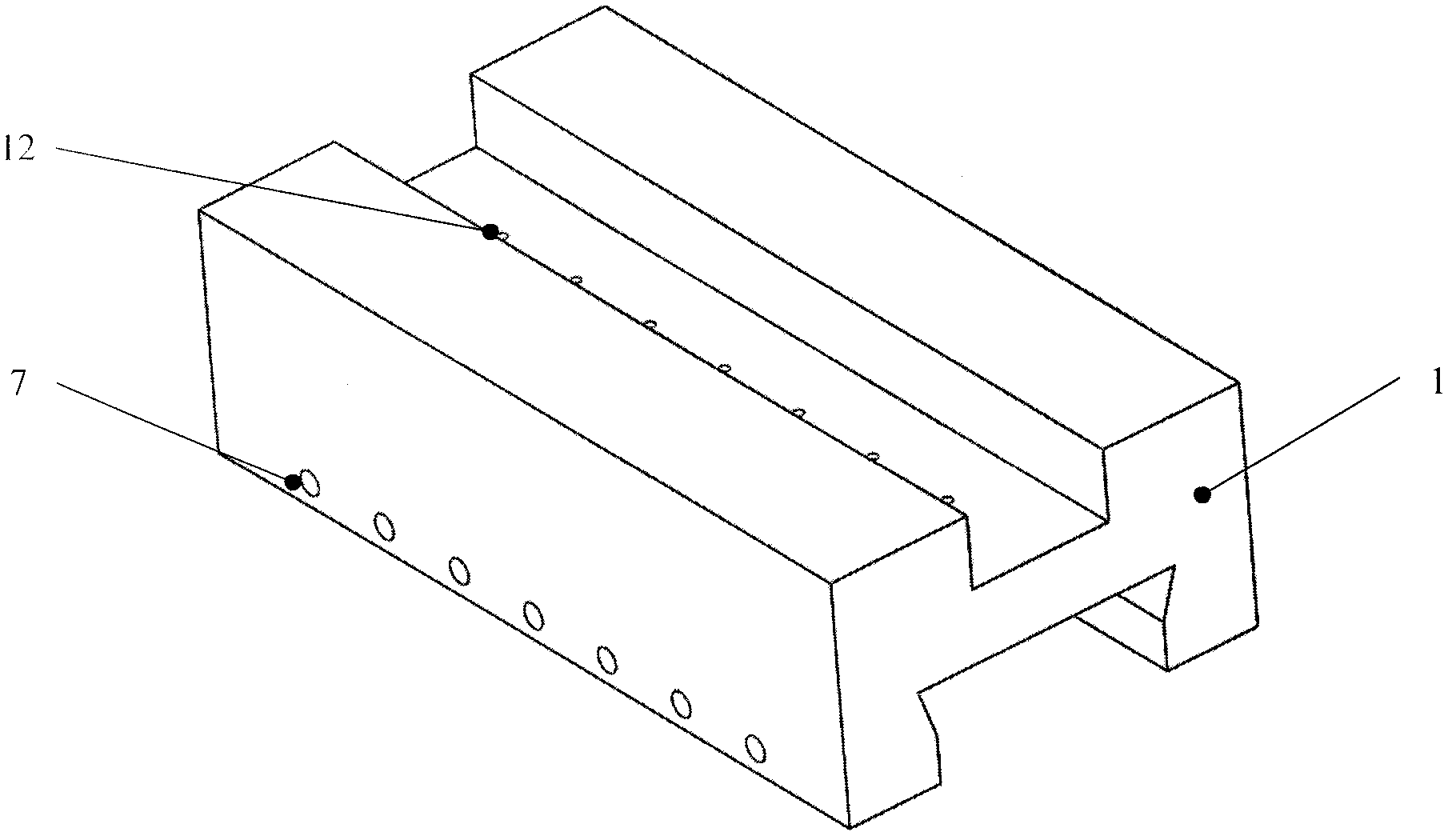

[0058] The upper surface of the convex mold fixing plate 1 and the upper mold base of the present invention is processed with grooves, and a number of through holes with a diameter of 2.5 mm are drilled on the bottom surface of the grooves to prepare thermocouples 12. The dovetail groove of the punch fixing plate 1 is coated with a high-temperature heat insulation coating 6. There are a number of screw holes with threads on one side of the punch fixing plate to facilitate fixing the punch 2, 11 by screws. The structure of the female mold fixing plate 5 corresponds to the structure of the male mold fixing plate 1.

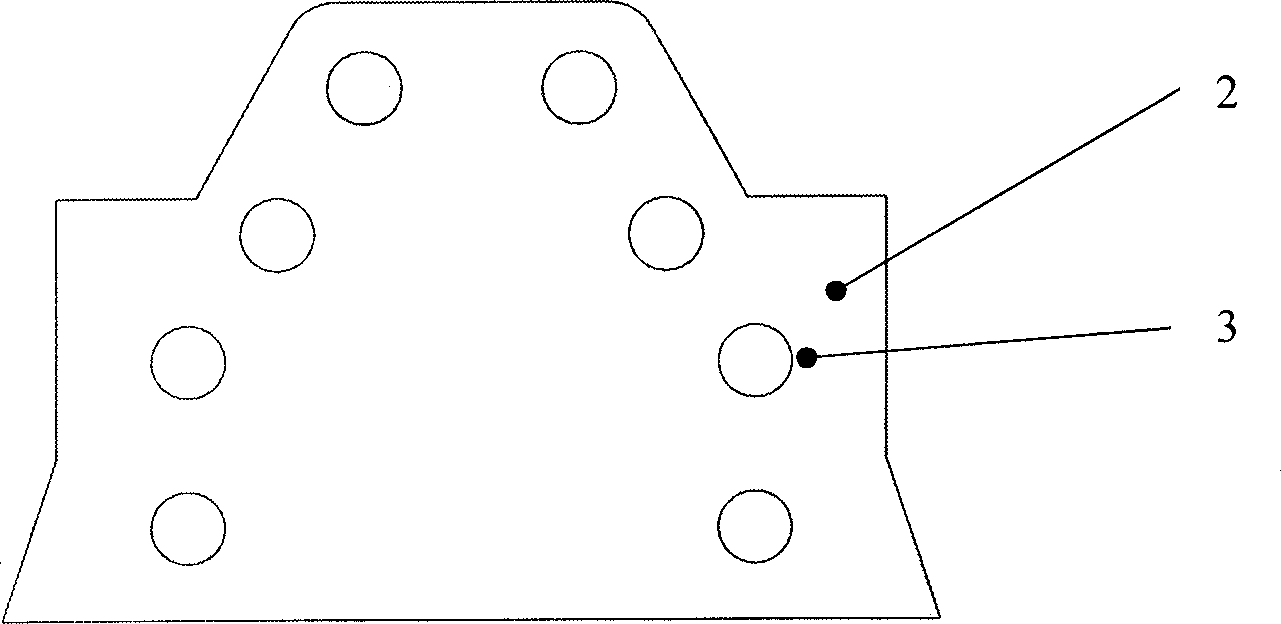

[0059] The convex mold cooling insert 2 is provided with a cooling water channel 3, and the cooling water channel 3 is connected by a connecting water pipe. In order to ensure that the surface temperature of the mold is as uniform as possible, multiple water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com