Continuous casting-direct rolling device for producing rod wire and section bar and method

A rod, wire, and production line technology, which is applied in the field of continuous casting-direct rolling devices for the production of rods, wires, and profiles, can solve problems such as high emissions and high energy consumption, and achieve the effects of simple equipment, improved yield, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

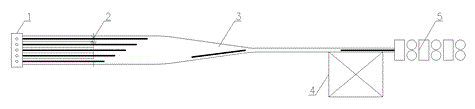

[0041] Embodiment one: as figure 1 As shown, the present invention provides a continuous casting-direct rolling device and method for producing rods, wires and profiles, including a continuous casting machine 1, a slab cutting device and a roller table 2 after cutting, a rapid heat preservation roller table 3, Billet off-line device 4 and steel rolling production line 5, the continuous casting machine 1 is a 5-machine 5-strand continuous casting machine, each stream is independently controlled, the casting speed is 1.5-3.5m / min, and the cross-sectional size of the continuous casting billet is 150mm×150mm The slab cutting device and the post-cutting roller table 2 adopt flame cutting device or hydraulic shearing device, with a fixed length of 12m, the post-cutting roller table is driven by a frequency conversion motor, the surface speed of the roller is 0.025-2m / s, and a heat preservation device is installed; The fast thermal insulation roller table 3 is a climbing roller table...

Embodiment 2

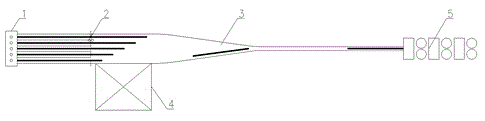

[0042] Embodiment 2: as figure 2 As shown, the present invention provides a continuous casting-direct rolling device and method for producing rods, wires and profiles, including a continuous casting machine 1, a slab cutting device and a roller table 2 after cutting, a rapid heat preservation roller table 3, Billet off-line device 4 and steel rolling production line 5. The difference from Example 1 is that the billet off-line device 4 is set at the slab cutting device and the cut roller table 2, before the fast heat preservation roller table 3, when the rolling line changes rolls and slots, accidents occur, and production is stopped for maintenance, Or when the hourly output of continuous casting is greater than the hourly output of steel rolling, the redundant billets are cooled off in rows through the billet off-line device 4 .

Embodiment 3

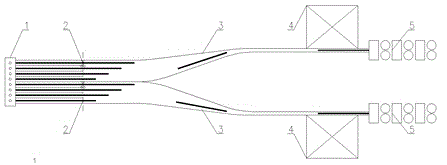

[0043] Embodiment 3: as image 3 As shown, the present invention provides a continuous casting-direct rolling device and method for producing rods, wires and profiles, including a continuous casting machine 1, a slab cutting device and a roller table 2 after cutting, a rapid heat preservation roller table 3, Billet off-line device 4 and steel rolling production line 5. The difference from Example 1 is that the device uses a multi-machine multi-stream continuous casting machine 1 corresponding to two steel rolling production lines 5 to match the output balance between continuous casting and steel rolling. The two steel rolling production lines can be used to produce rods and wires of the same product , profile production line, or bar, wire, and profile production line for the production of different products. The continuous casting machine adopts a ladder-shaped billet discharge method. After the billets are cut successively, according to the output matching situation, a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com