Device and method for shortening continuous tapping time interval of rolled steel production line

A time interval and production line technology, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of large volume of rolling mill rolls, failure to recognize normally, and lack of accuracy, so as to shorten the rolling interval time , save no-load current consumption, and ensure the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

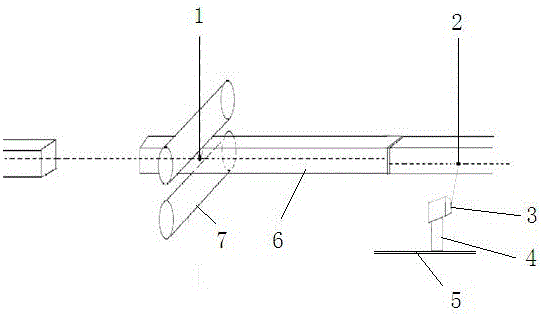

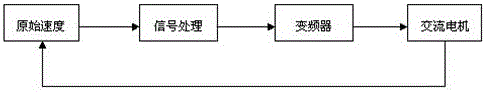

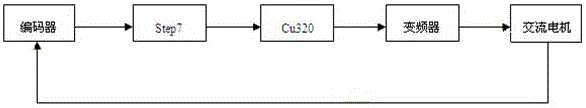

[0024] The technical problem to be solved by this invention is:

[0025] First, billets are rolled end-to-end on the line before being bitten into the first stand. Since the tapping rhythm of the heating furnace is affected by the cycle time of the walking beam in the furnace, there is a difference in the tapping time between the root steels, and there is a distance between the two billets before and after they are tapped. This requires adjustment of the advance rate of the roller table speed that carries the billet before entering the first rolling mill. Along the advancing direction of the steel billet, set the speed advance rate of each section of the roller table in turn from high to low, so that the latter billet coming out of the furnace mouth will continuously catch up with the previous billet, before entering the first rolling mill, at the latest before entering the rolling mill. The moment the mill is connected end to end. These can be set by post operators.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com