Sensing control system

A sensor control and delay control technology, applied in the field of sensor control systems, can solve the problems of lack of realism, insecurity, huge differences, etc., and achieve the effect of more accurate, real and effective sensed sound signals, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

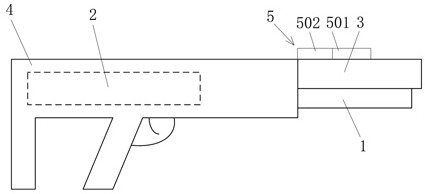

[0045] According to one embodiment of the present invention, there is an RC delay circuit or a time relay electrically connected to the sensing module (ie each sensor) and the laser transmitter 1 on the circuit board. In this way, when the sensor senses the signal and converts it into an electrical signal, it can realize the delay control of the laser transmitter to emit laser pulses through the RC delay circuit or time relay.

[0046] In this embodiment, in order to make the emission of the laser pulse as much as possible the same as the emission effect of the actual bullet warhead, the laser pulse emitted by the laser transmitter 1 should be after the circuit board receives the sound signal or receives the sound signal and the recoil signal. A delay of 3ms triggers the laser transmitter 1 to emit laser pulses.

[0047] According to the above-mentioned embodiment of the present invention, even if the laser is used to replace the real warhead, it can ensure that the trainers h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com