Small cross steel tapping control method for continous steel billet neating furnace

A billet heating and control method technology, applied to lighting and heating equipment, furnaces, crucible furnaces, etc., can solve the problems of not too many steel blocks, product quality fluctuations, large fluctuations, etc., to achieve accurate calculation values and improve Effect of Thickness Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

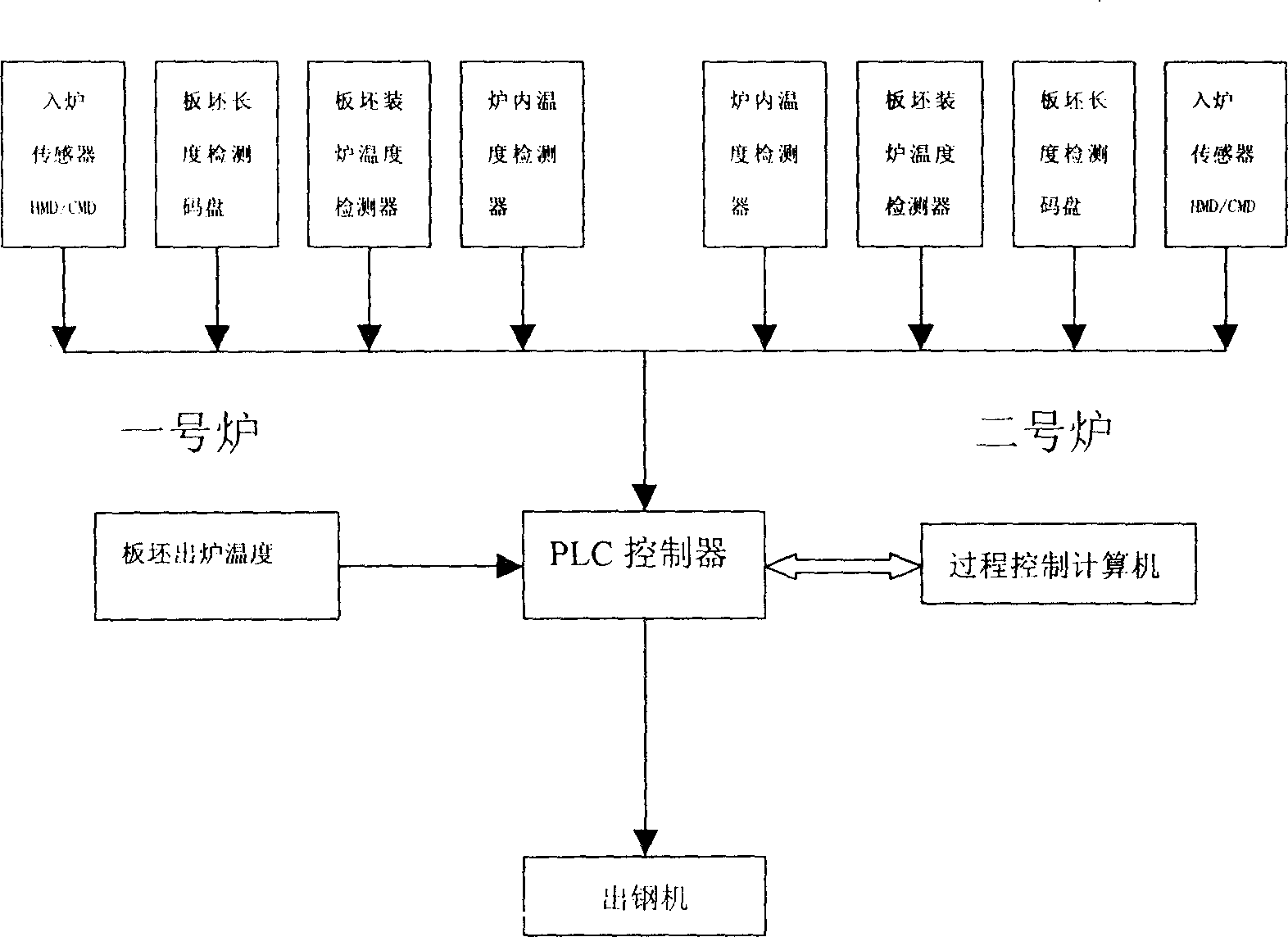

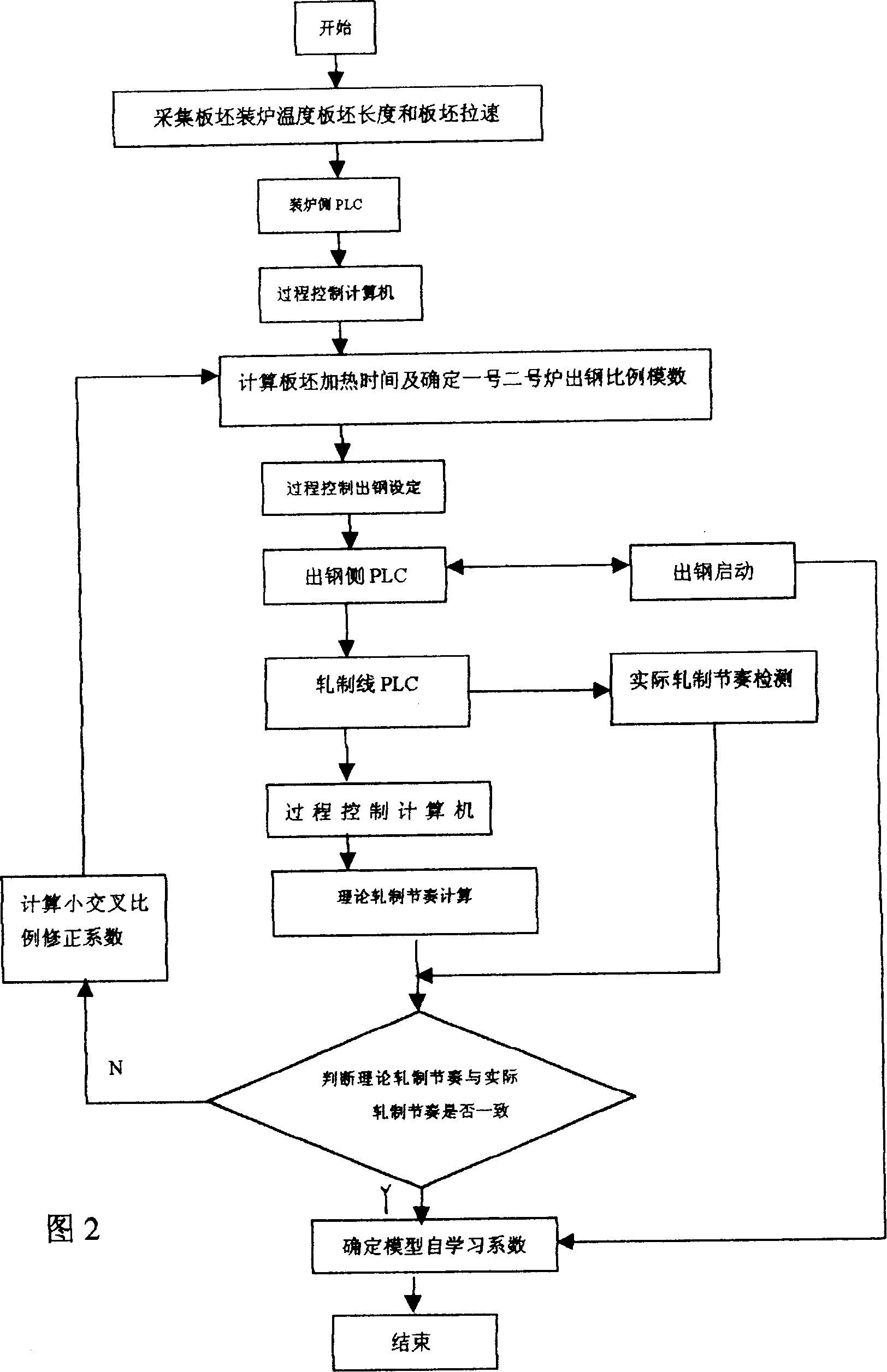

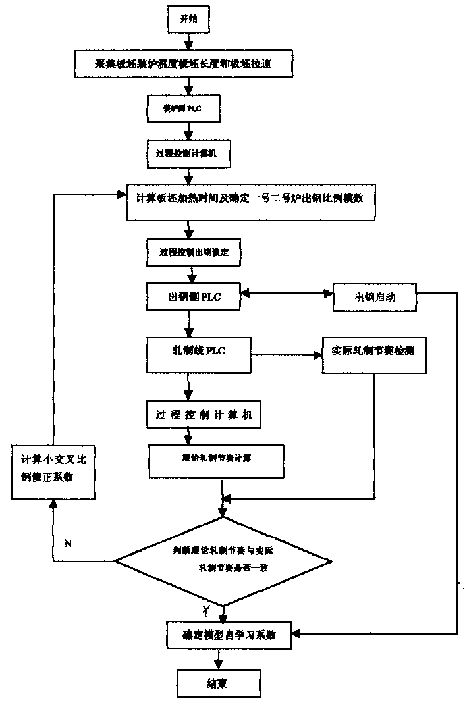

[0034] Such as figure 1 As shown in , 2, a furnace sensor and a slab length detection code disc are installed on the steel loading side of the two heating furnaces. If it is a hot billet or a cold billet, a temperature detector is installed in the furnace, and a slab discharge detector is installed at the tapping port to detect the length of the slab in the two heating furnaces, the temperature of the billet in the furnace, and the temperature in the furnace. The slab pulling speed is measured by the PLC of the rolling line, and these signals are sent to the PLC and the process control computer, and then according to the temperature requirements of the furnace, through calculation and comparison with the rolling rhythm of the rolling line, the tapping of the two furnaces is optimized. The modulus of the block number ratio is used to complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com