An optimization method of mineral material grading based on mineral material gap ratio

A technology of gradation optimization and void ratio, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problem that the optimal asphalt ratio is far apart, VMA and void ratio are difficult to meet the specification requirements, and gradation optimization has no Realize and other problems, to achieve the effect of accurate and reasonable calculation value, saving engineering cost and shortening the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the mineral material gradation optimization method based on the mineral material gap ratio includes the following steps:

[0037] Step 1. Sieve the mineral material to obtain n grades of graded mineral materials with different particle sizes, wherein the particle size of the i-th graded mineral material is d i , the mass passing percentage of grade i graded mineral material is m i ; The i=1, 2, 3, ..., n, n is a natural number greater than 4;

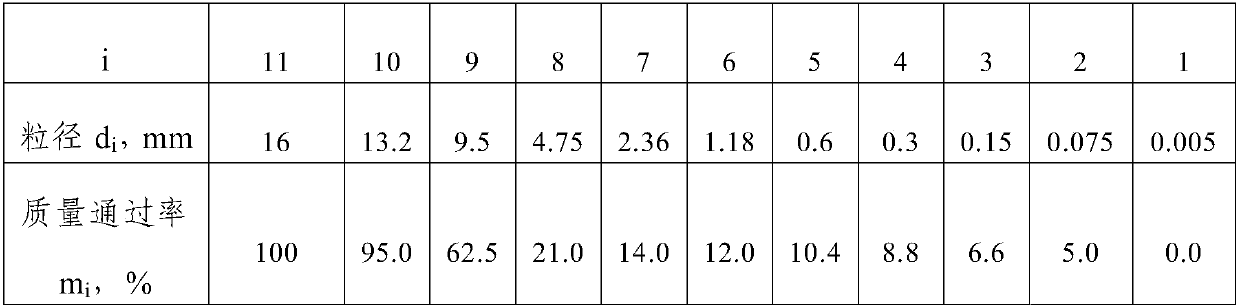

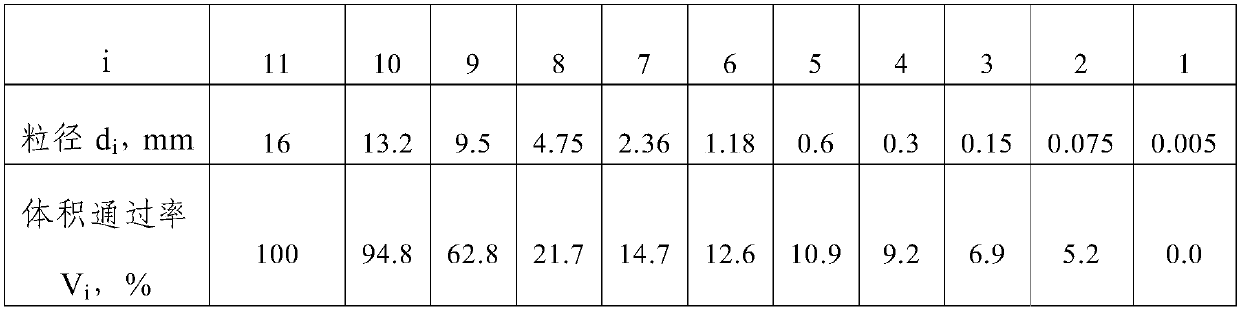

[0038] The gradation composition of the mineral material in this embodiment is shown in Table 1.

[0039] Table 1 Gradation Composition (Quality Parameters) of Mineral Materials in Example 1

[0040]

[0041] As can be seen from Table 1, the mineral material gradation in this embodiment includes n=11 different particle sizes, wherein the maximum particle size is 16mm, and the minimum particle size is 0.005mm;

[0042] Step 2, passing the mass of the i-th grade graded mineral material described in step 1 ...

Embodiment 2

[0065] In this embodiment, the mineral material gradation optimization method based on the mineral material gap ratio includes the following steps:

[0066] Step 1: Sieve the mineral material to obtain n grades of graded mineral materials with different particle sizes, and the particle size of the i grade graded mineral material is d i , the mass passing percentage of grade i graded mineral material is m i ; The i=1, 2, 3, ..., n, n is a natural number greater than 4;

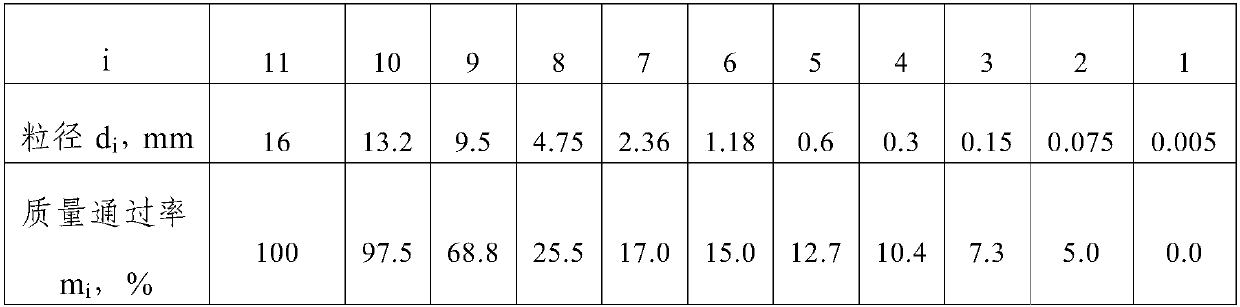

[0067] The gradation composition of the mineral material in this embodiment is shown in Table 6.

[0068] Table 6 The gradation composition (quality parameters) of the ore material in Example 2

[0069]

[0070] As can be seen from Table 6, the mineral material gradation of this embodiment includes n=11 different particle sizes, wherein the maximum particle size is 16mm, and the minimum particle size is 0.005mm;

[0071] Step 2, passing the mass of the i-th grade graded mineral material described in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com