Mineral aggregate gradation optimization method based on mineral aggregate void rate

A technology of gradation optimization and clearance ratio, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving. Real realization and other problems, to achieve the effect of accurate and reasonable calculation value, saving engineering cost and improving engineering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the mineral material gradation optimization method based on the mineral material gap ratio includes the following steps:

[0037] Step 1. Sieve the mineral material to obtain n grades of graded mineral materials with different particle sizes, wherein the particle size of the i-th graded mineral material is d i , the mass passing percentage of grade i graded mineral material is m i ; The i=1, 2, 3, ..., n, n is a natural number greater than 4;

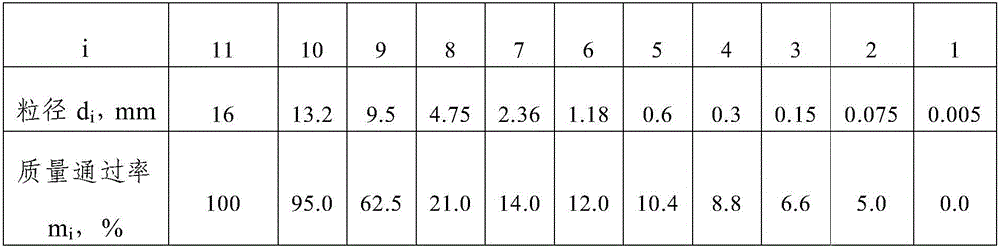

[0038] The gradation composition of the mineral material in this embodiment is shown in Table 1.

[0039] The gradation composition (quality parameter) of table 1 embodiment 1 mineral material

[0040]

[0041] As can be seen from Table 1, the mineral material gradation in this embodiment includes n=11 different particle sizes, wherein the maximum particle size is 16mm, and the minimum particle size is 0.005mm;

[0042] Step 2, passing the mass of the i-th grade graded mineral material described in step ...

Embodiment 2

[0065] In this embodiment, the mineral material gradation optimization method based on the mineral material gap ratio includes the following steps:

[0066] Step 1: Sieve the mineral material to obtain n grades of graded mineral materials with different particle sizes, and the particle size of the i grade graded mineral material is d i , the mass passing percentage of grade i graded mineral material is m i ; The i=1, 2, 3, ..., n, n is a natural number greater than 4;

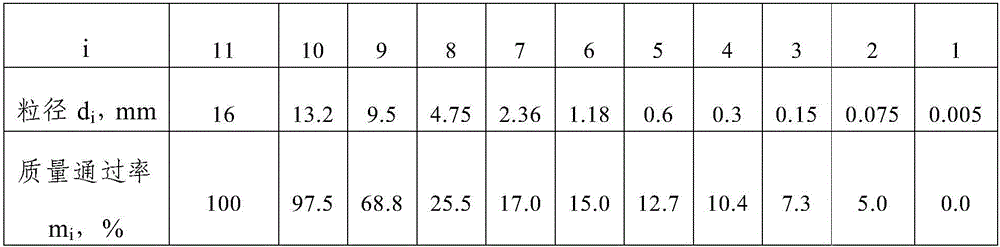

[0067] The gradation composition of the mineral material in this embodiment is shown in Table 6.

[0068] The gradation composition (quality parameter) of table 6 embodiment 2 mineral materials

[0069]

[0070] As can be seen from Table 6, the mineral material gradation in this embodiment includes n=11 different particle sizes, wherein the maximum particle size is 16mm, and the minimum particle size is 0.005mm;

[0071] Step 2, passing the mass of the i-th grade graded mineral material described in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com