A closed-loop control method for driving motor torque in electric vehicles

A drive motor, torque closed-loop technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve problems such as insufficient torque output, rotor temperature rise, torque output reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Embodiments of the present invention are described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[0078] Such as figure 1 As shown, the vehicle control unit 1 sends a torque command T to the motor controller 2 through the CAN bus cmd and three-phase short-circuit control T psc ;

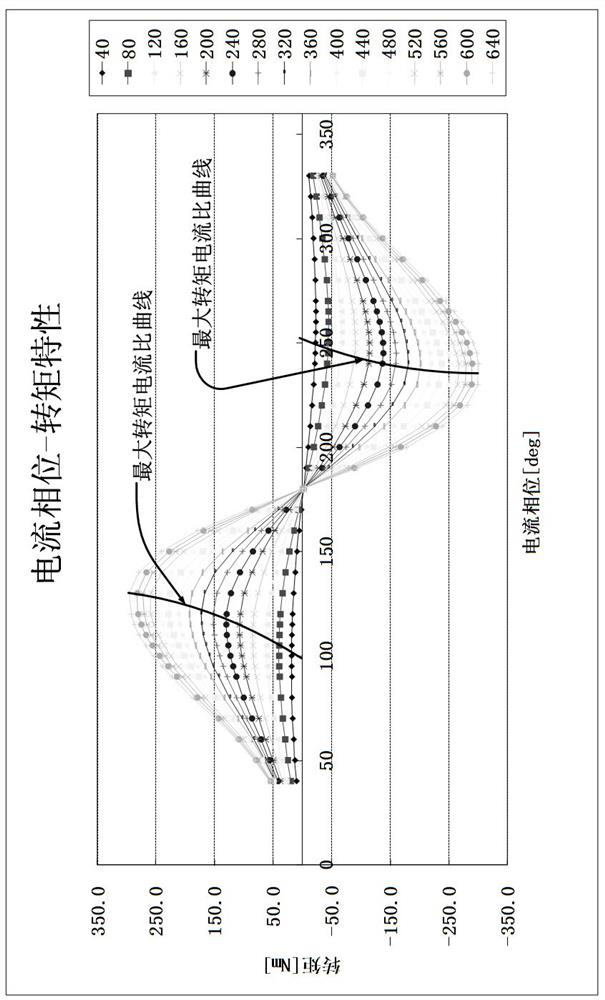

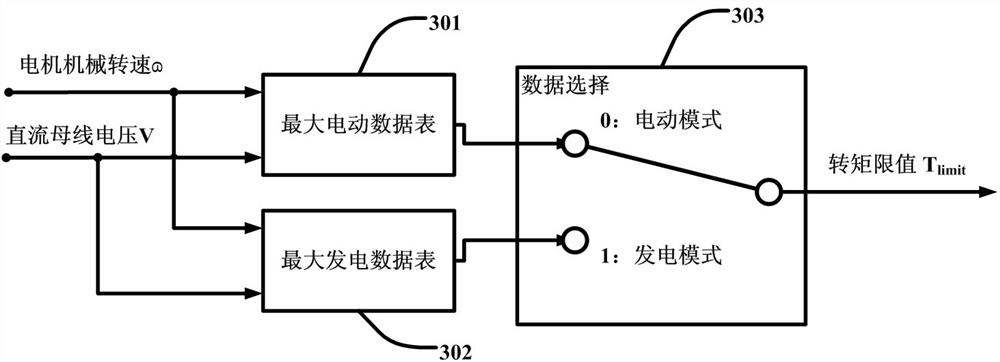

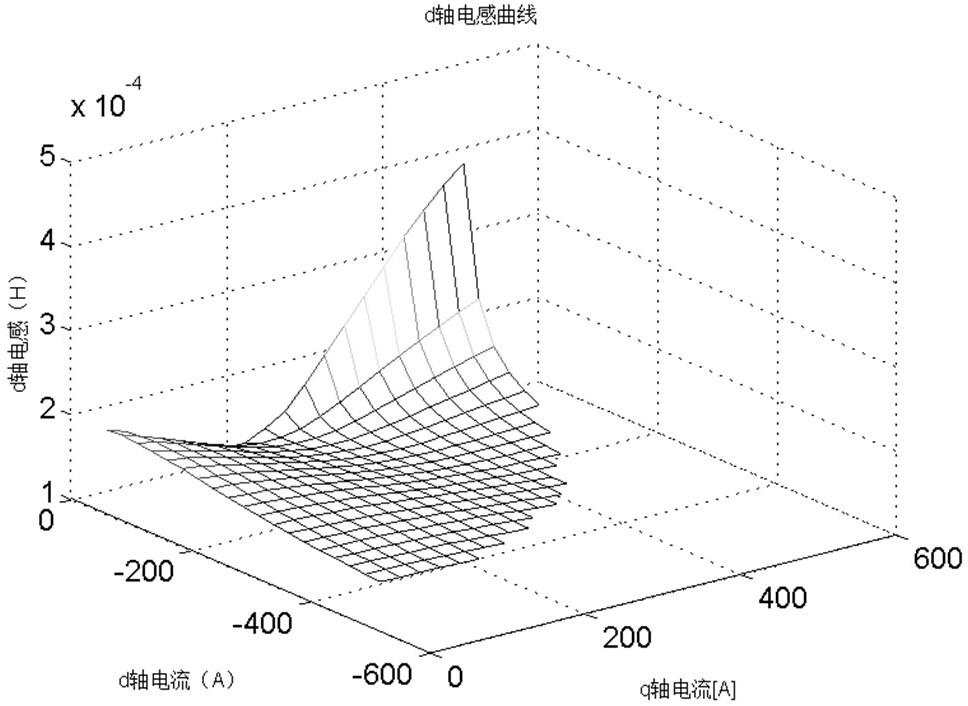

[0079] The motor controller 2 is composed of a CAN instruction decomposition unit 21, a torque PI adjustment module 22, a right-angle axis current instruction generation unit 23, a right-angle axis current PI adjustment module 24, a voltage decoupling control unit 25, a space vector modulation unit 26, a position and speed processing unit 27, CLARK&PARK conversion unit 28, torque online calculation module 29 and torque limit generation module 30; the motor controller 2 controls T psc and the mechanical speed ω of the motor to judge whether to carry out active short-circuit control, while satisfying T psc is 1 and the mechanical spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com