Corn threshing machine

A technology for thresher and corn, applied in threshing equipment, agricultural machinery and implements, application and other directions, can solve the problems of low working efficiency of corn thresher, difficult to improve working efficiency, etc., and achieve convenient and fast input, simple structure and high working efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

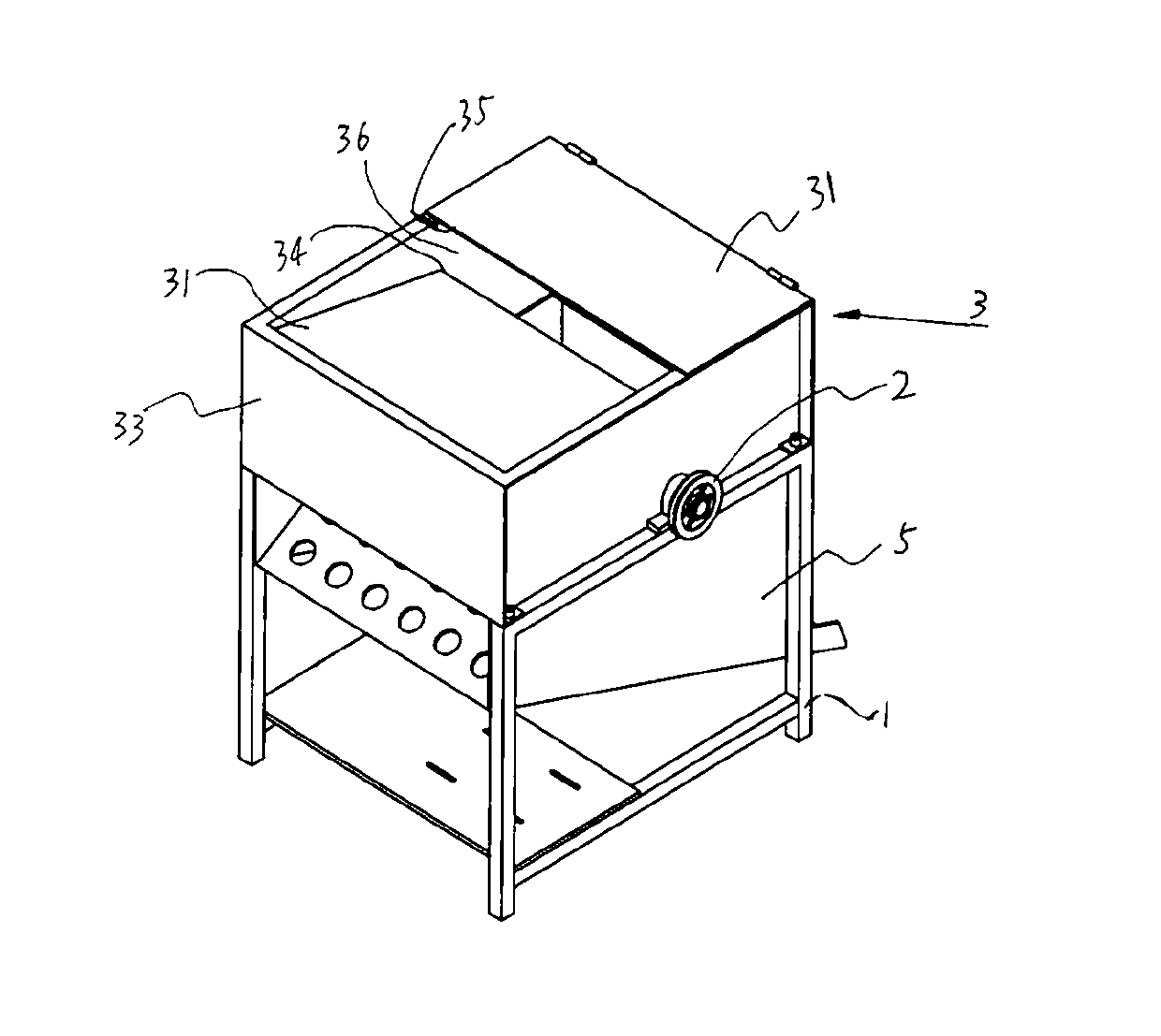

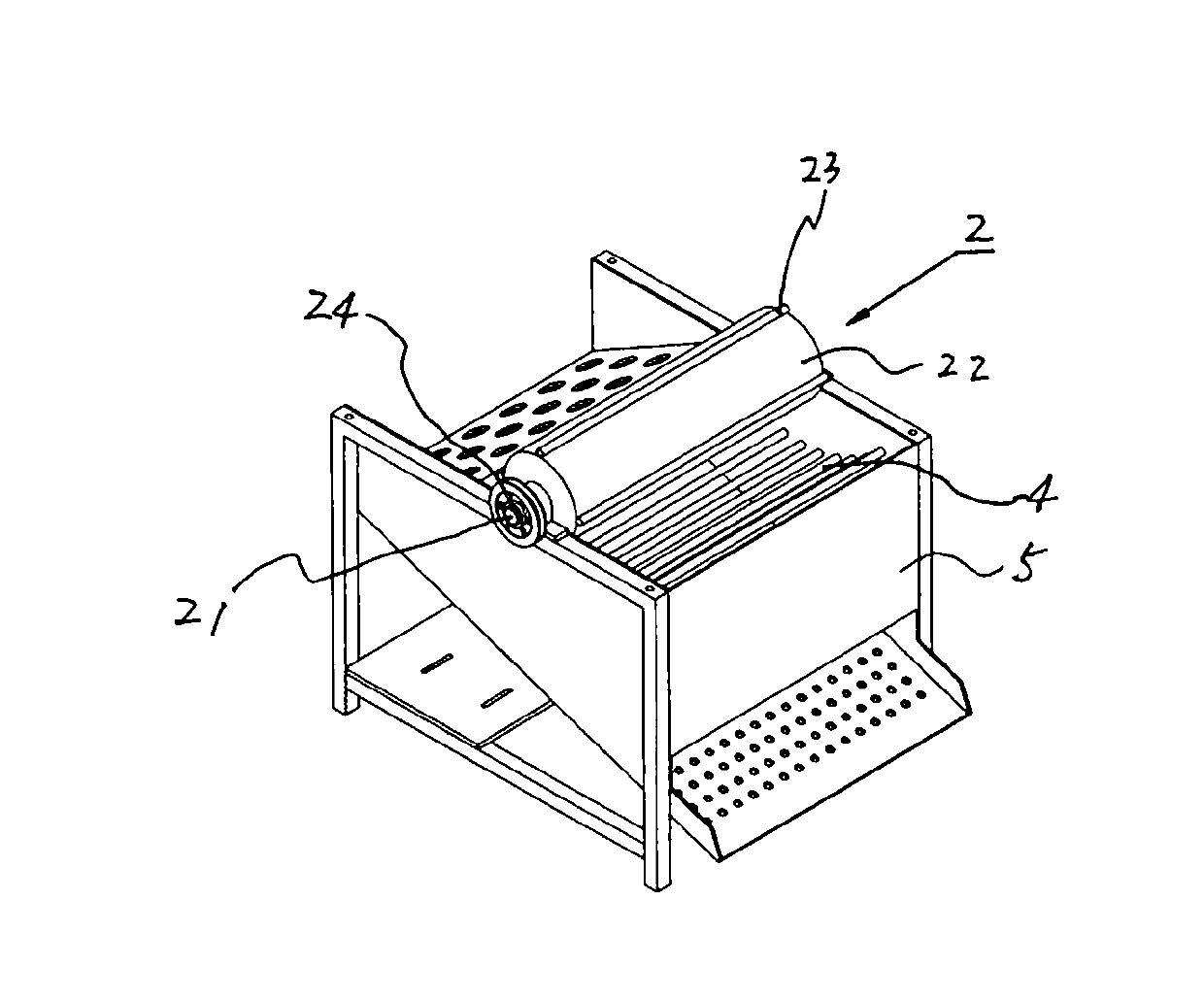

[0019] see Figure 1 to Figure 3 , these three drawings provide the overall structure of the appearance of an embodiment of the corn thresher proposed by the present invention. The threshing machine includes a frame 1 , a threshing cylinder 2 , a corn feeding assembly 3 , an arc-shaped limiting screen 4 , a material conveying assembly 5 and a limiting member 6 .

[0020] The threshing cylinder 2 is installed on the top of the frame 1, and it is composed of a grained rod cylinder. The grained rod cylinder includes a cylinder 22 limited by a rotating shaft 21 and a strip-shaped rib 23 axially arranged on the cylinder 22. There are 6 shaped ribs 23, and two adjacent strip shaped ribs 23 are radially spaced at equal distances. The strip-shaped ribs 23 are parts used for removing corn kernels, the number of which can be determined according to the diameter of the cylinder 22, usually 2-6 strip-shaped ribs 23 can be set, and the strip-shaped ribs 23 can be straight rods , can ...

Embodiment 2

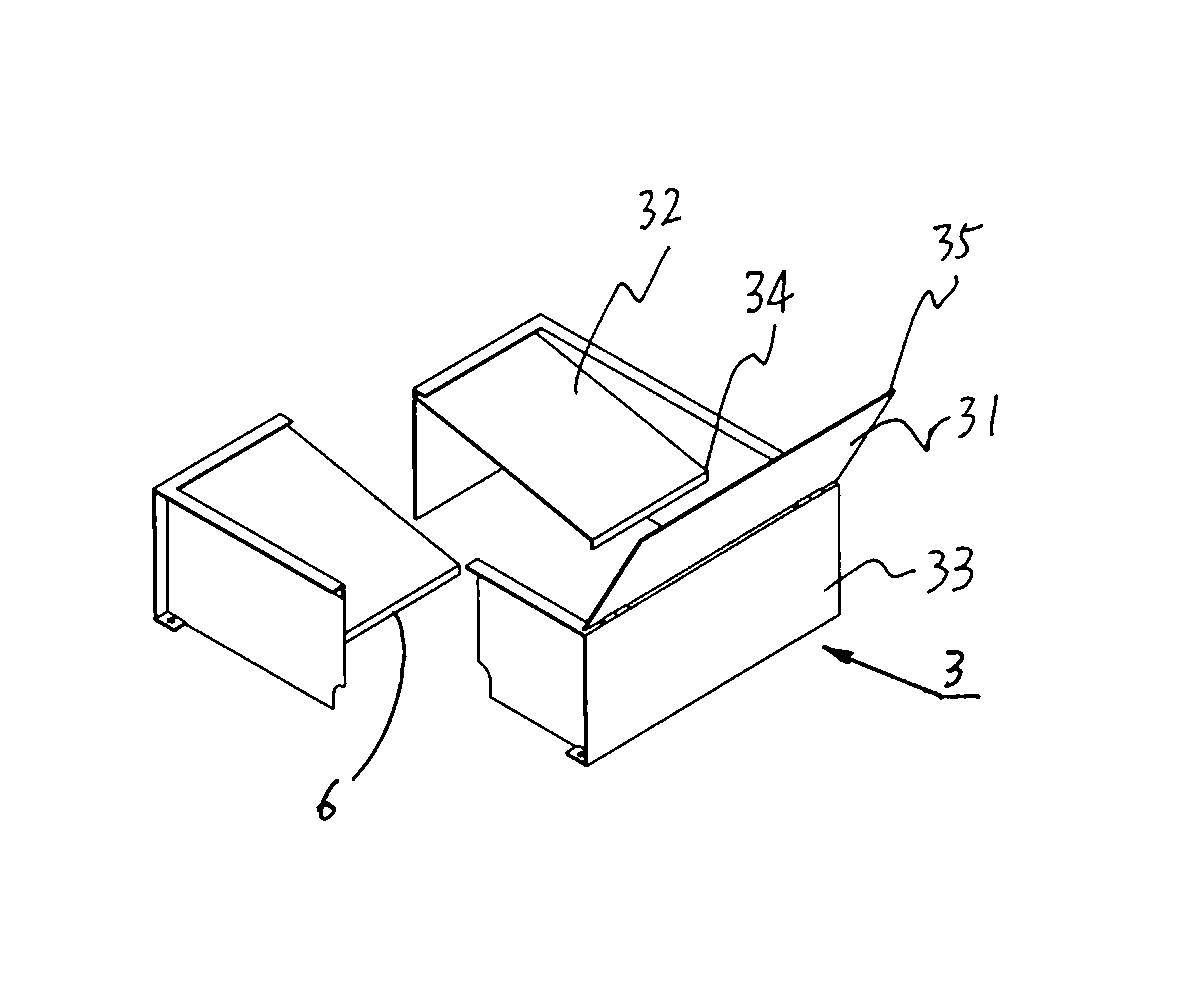

[0026] see Figure 5 and Image 6 , these two drawings provide the appearance structure of another embodiment of the corn thresher proposed by the present invention. The threshing machine also includes a frame 1 , a threshing cylinder 2 , a corn feeding assembly 3 , an arc-shaped limiting screen 4 , a feeding assembly 5 and a limiting member 6 . The structures of the frame 1, the threshing drum 2, and the arc-shaped limit screen 4 are basically the same as those of the embodiment 1, and will not be described in detail in this embodiment.

[0027] The corn feeding assembly is installed on the top of the frame 1, which includes a frame 3 made of plates, the frame 3 is a rectangular base 31 made of three vertical plates, and the top of the base 31 is provided with a frame made of plates. The cross-section is V-shaped and is arranged on the shading plate 33 opposite to the corn feeding portion 32, and the end portion of the corn feeding portion 32 and the end portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com