Corn cob crushing device and corn harvesting device

A corn crushing and cob-breaking technology, applied in harvesters, threshing equipment, cutters, etc., can solve the problems of low harvest efficiency, mildew threshing of corn, waste of manpower and material resources, etc., and achieve the effect of improving harvest efficiency and reducing huge losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawings and examples.

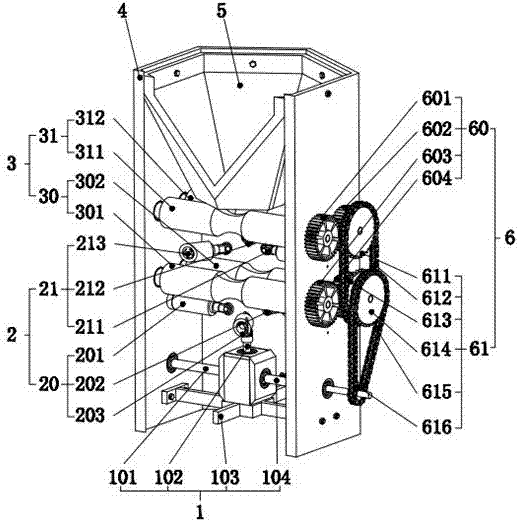

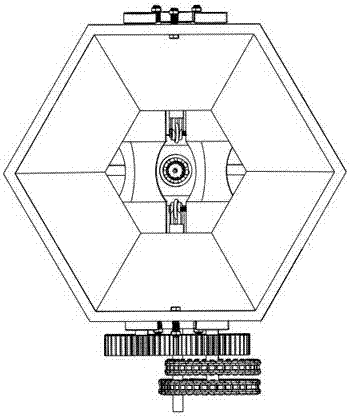

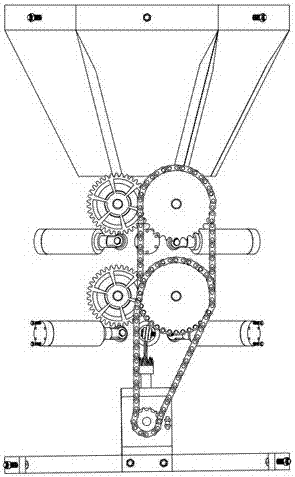

[0028] Such as Figure 1-9 Shown, a kind of broken corn cob device, it comprises broken core mechanism 1, elastic positioning mechanism 2, clamping and conveying mechanism 3, frame 4, feeding hopper 5 and transmission mechanism 6; At the upper end, the elastic positioning mechanism 2 and the clamping conveying roller 3 are installed in the frame 4 at the lower end of the feeding hopper 5 in a staggered manner up and down, and the transmission mechanism 6 is installed outside the frame 4 . The broken core mechanism 1 comprises a power output shaft 101, a broken core drill 102, a transmission case frame 103, a power input shaft 104 and a bevel gear 105; the transmission case frame 103 is fixed inside the lower end of the frame 4, and the power output shaft 101 is installed on On the frame 4 on the opposite side of the transmission box frame 103 and the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com