Method for diagnosing faults of pneumatic regulating valve based on particle swarm optimization

A pneumatic control valve, particle swarm optimization technology, applied in the testing of mechanical components, testing of fluid tightness, testing of machine/structural components, etc., can solve problems such as fault state deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing.

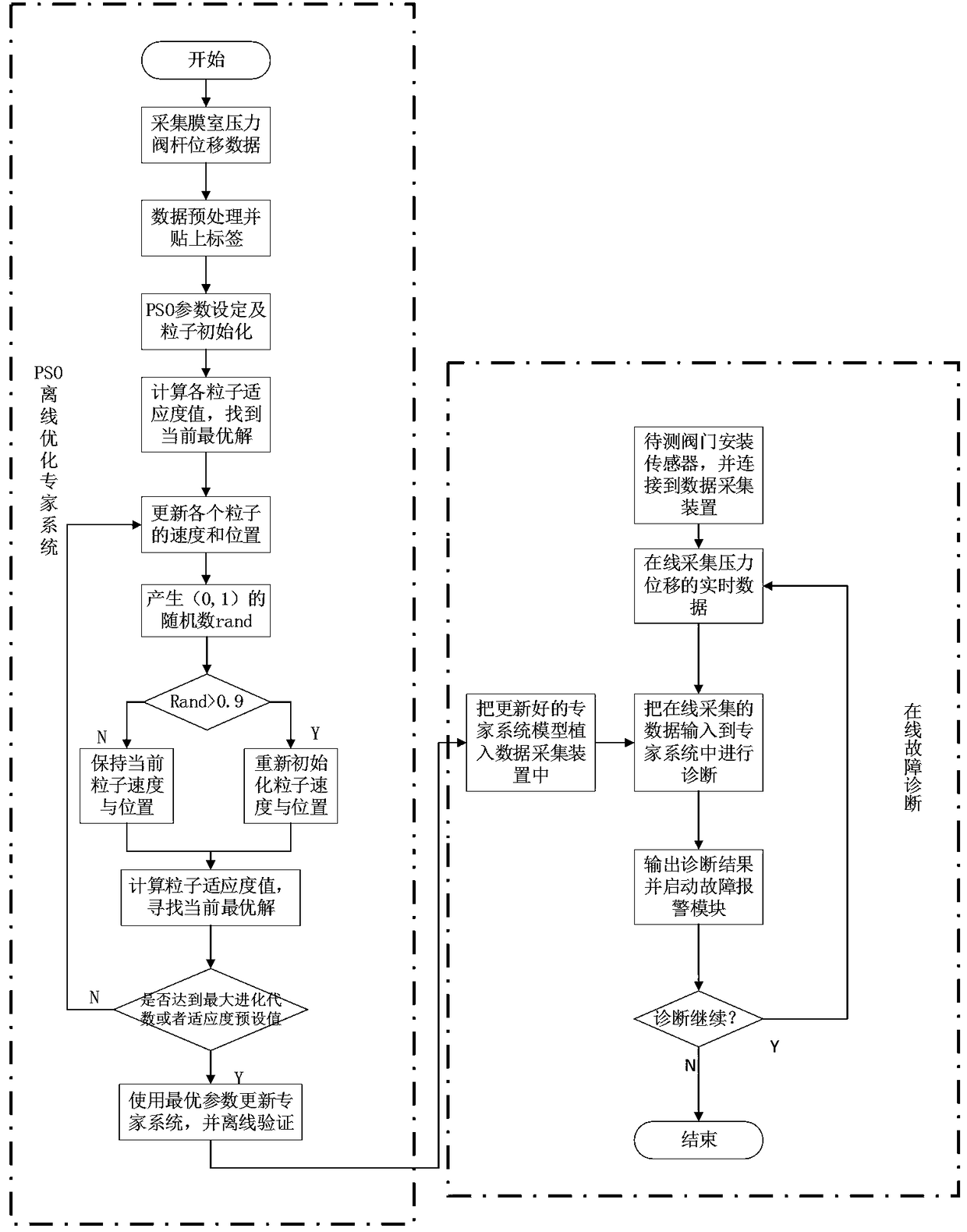

[0065] like figure 1 As shown, a method for fault diagnosis of pneumatic control valve based on particle swarm optimization includes the following steps:

[0066] A. Using adaptive mutation particle swarm algorithm to optimize the diagnostic expert system offline

[0067] A.1. Data collection:

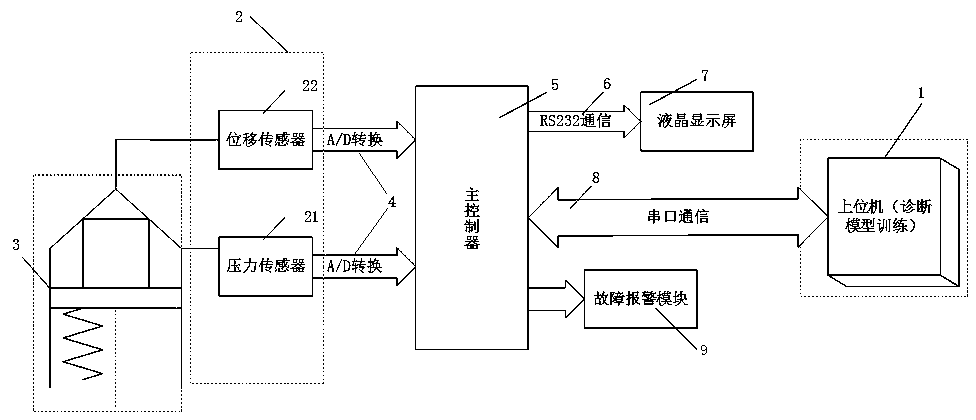

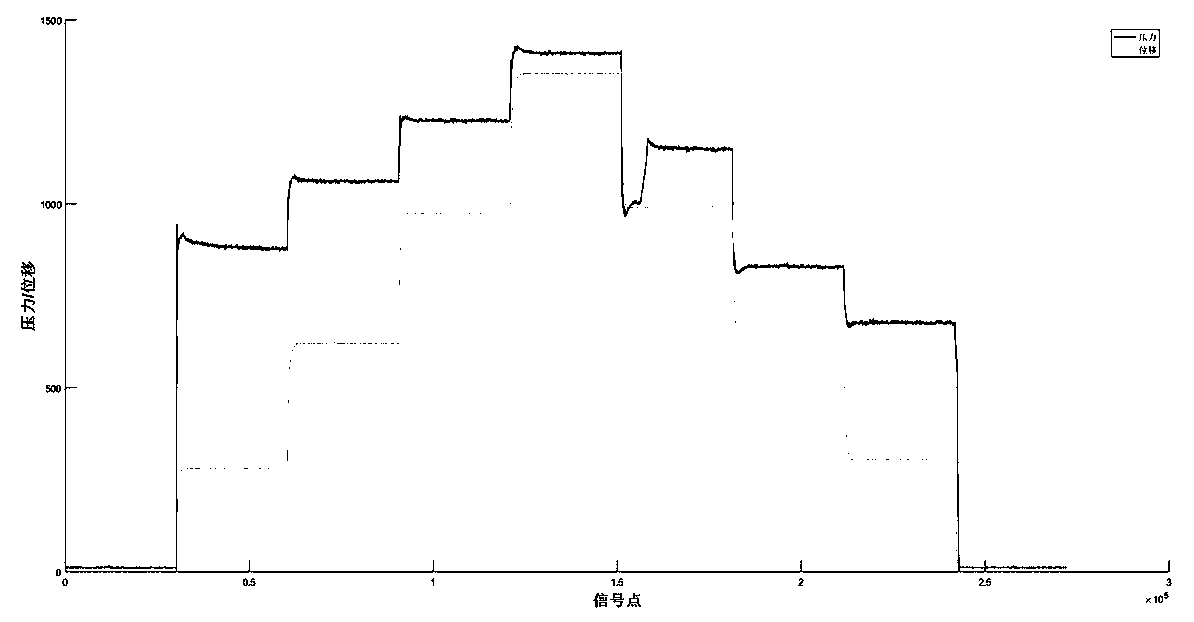

[0068] Install a displacement sensor and a pressure sensor at the reserved place next to the screw cap of the pneumatic control valve and the air supply hole outside the membrane, and give a 4-20mA current input signal according to the percentage step signal, and collect the pressure and displacement data through the data acquisition device. And transmit the collected data to the host computer through serial port communication;

[0069] In this embodiment, the faults of the pneumatic control valve are divided into C=6 types, namely, air leakage fault, foreign matter fault on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com