Full-flow intelligent diagnosis and optimized operation system for industrial furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

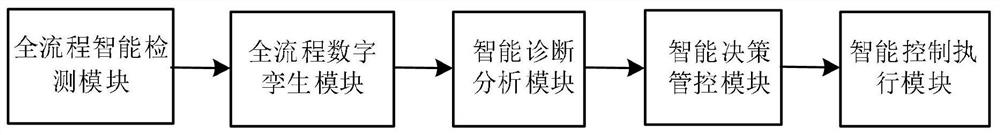

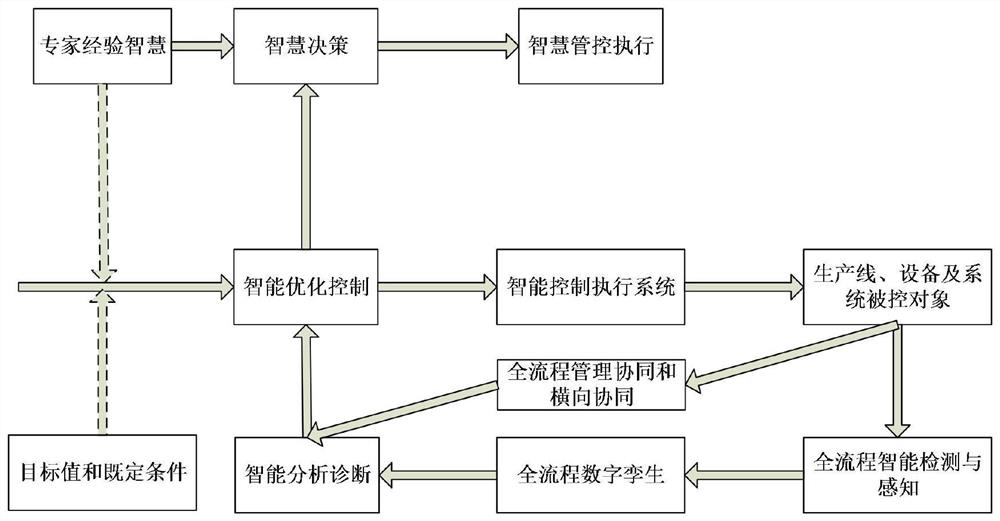

[0030] This embodiment discloses a full-process intelligent diagnosis and optimization operation system of an industrial furnace, which is characterized in that it includes: a full-process intelligent detection module, a full-process digital twin module, an intelligent diagnosis and analysis module, an intelligent decision-making management and control module, and an intelligent control execution module ;in:

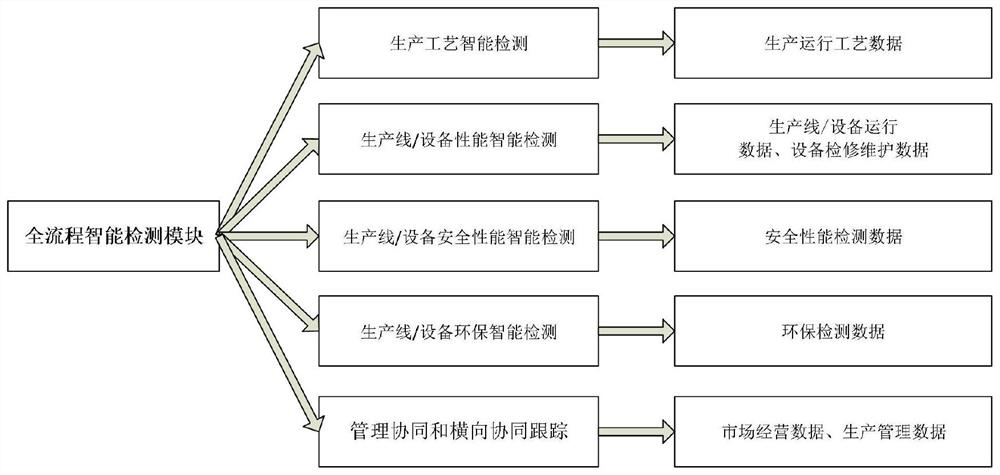

[0031] The whole process intelligent detection module is used for intelligent detection of the whole process of industrial furnaces, including intelligent detection of production process, intelligent detection of production line / equipment performance, intelligent detection of production line / equipment safety performance, intelligent detection of production line / equipment environmental protection, production line / equipment and The comprehensive perception and detection of all links of the system forms the core database data.

[0032] Specifically, the core database data i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com