Corn threshing machine

A technology for thresher and corn, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of farmers' palm pain, occupation of farmers' time, eardrum impact, etc., to save the later process of slag removal, reduce The effect of small noise transmission and time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

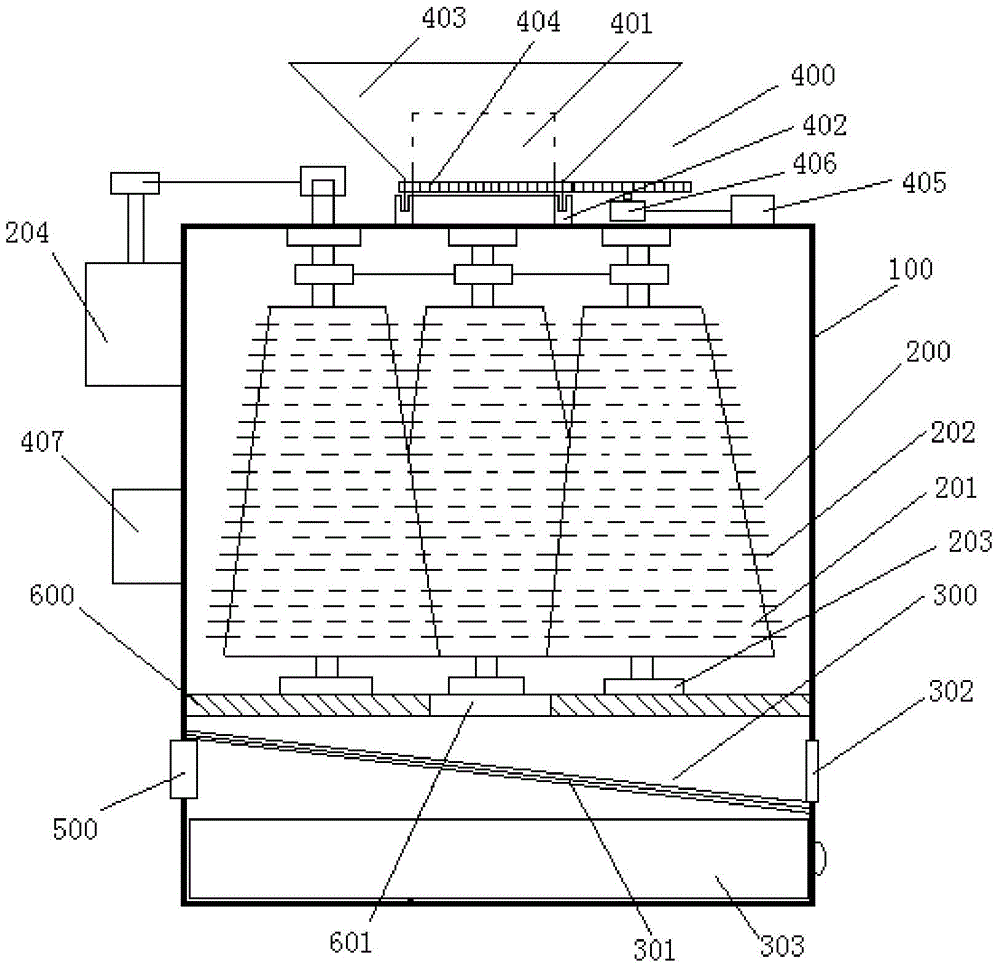

[0023] Such as Figure 1-2 As shown, the present invention provides a corn thresher, comprising a housing 100, a threshing device 200 disposed in the housing, and a core separation device 300 disposed in the housing, the core separation device 300 is located in the Below the threshing device 200, wherein,

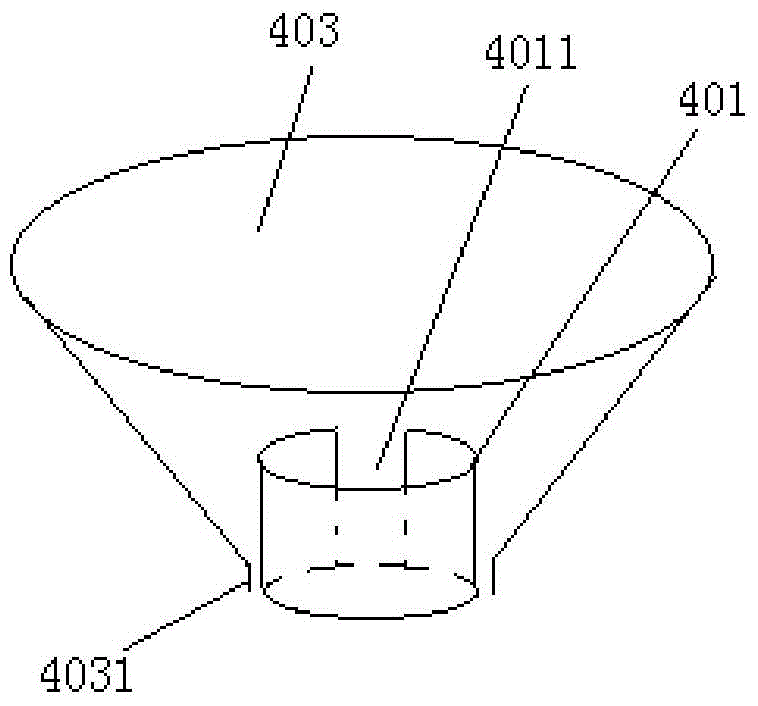

[0024] The shell of the housing 100 is provided with a sound-insulating layer (not shown), and the thickness of the sound-insulating layer accounts for 1 / 2 of the thickness of the shell (this thickness can not only ensure a better sound-insulating effect, but also reduce the overall The weight of the housing is convenient for farmers to carry), meanwhile, the thresher also includes: an ear of corn feeding device 400 arranged on the top of the housing, and the ear of corn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com