Tobacco leaf threshing and destemming technical method and special equipment thereof

A process method and tobacco leaf technology, applied in the direction of chemical instruments and methods, tobacco, applications, etc., can solve the problems of increasing the complexity of the process flow, increasing energy consumption, and increasing the number of air separation units, so as to achieve the reduction of leaf content rate and gas consumption Reduction, the effect of system energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with accompanying drawing:

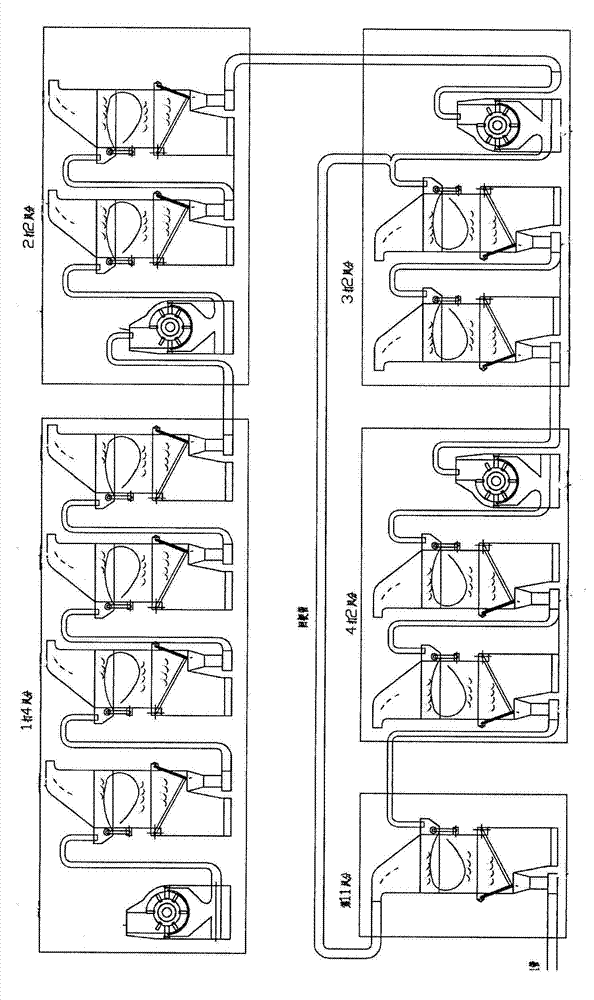

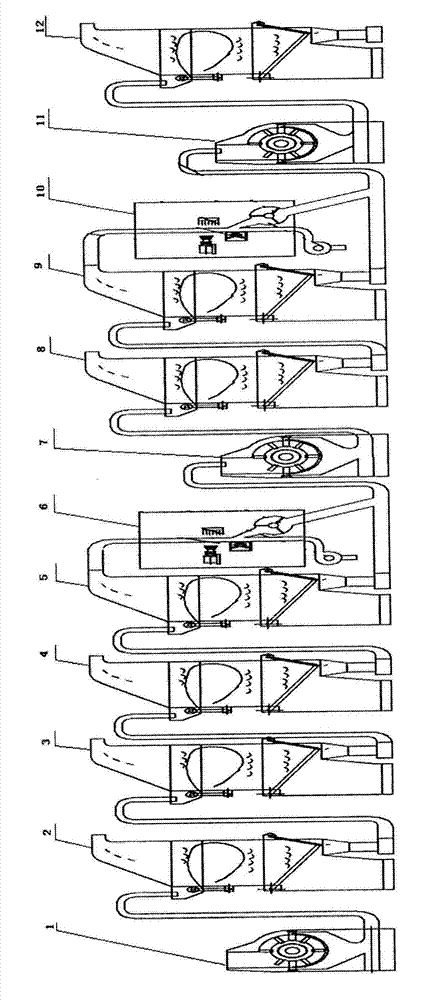

[0027] Such as figure 2 Shown: the raw tobacco after primary roasting is pretreated by loose leaf moistening, screening, etc., and then enters the first threshing section according to certain temperature, humidity and flow conditions, and the tobacco stems and leaves are initially torn and separated in the first stage threshing unit 1 , the air separators 2, 3, and 4 connected in series adopt lower wind speeds, and the upstream materials are separated to output some pure blades, and the downstream materials enter the fourth-stage air separator 5. In the air separator 5, all the free pure leaves and some stalked leaves are sorted out by adopting a relatively high wind speed uplink material, and the downlink material enters the second-stage threshing unit 7, and the uplink material further passes through the first-stage spectral destemming unit 6 to separate the uplink material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com