Axial shearing corn threshing machine and corn threshing method

A shearing, thresher technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of broken corn cob and large damage to corn kernels, and achieve complete effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

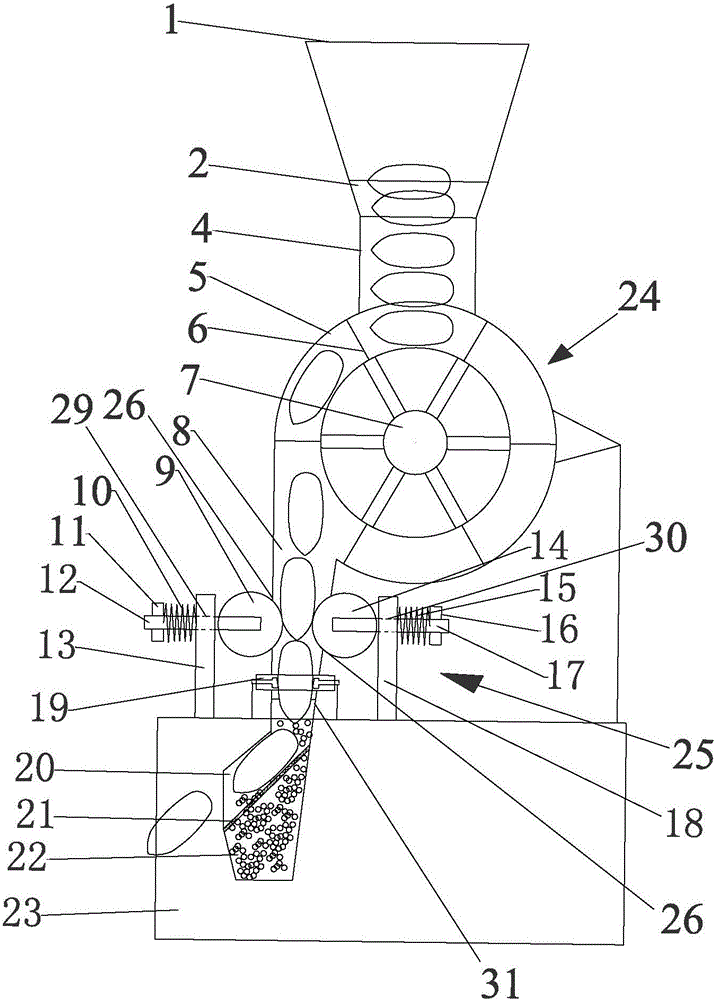

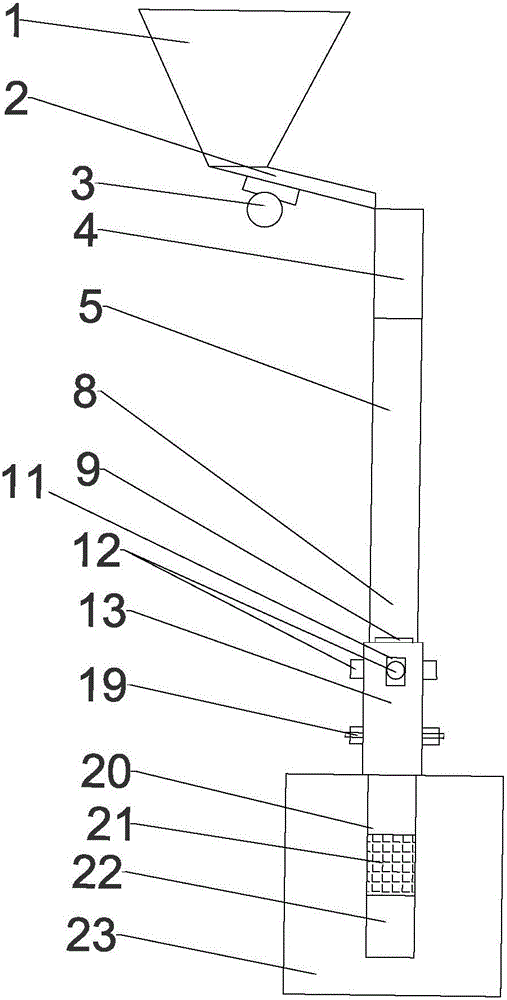

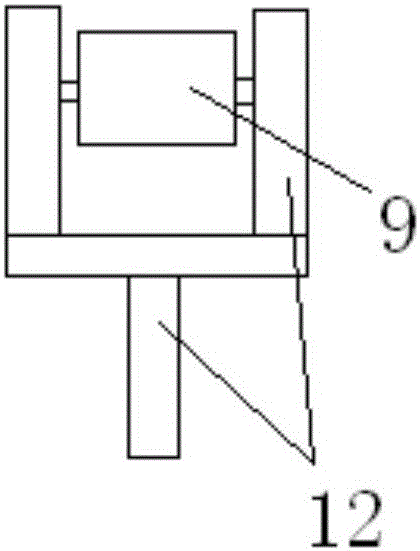

[0024] Such as Figure 1-6 Described axial shear corn thresher, it comprises silo 1, rolling plate 2, buffer bin 4, base 23, the impeller feeder 24 that is installed on the base 23, the self-adaptive pair that is installed on the base 23 Roller conveying device 25, self-adaptive annular axial threshing device 19 installed on the base 23, wherein, the self-adaptive annular axial threshing device 19 includes a threshing device housing 1901, four cutter head installation shafts 1902, four Limit spring 1903, four cutter heads 1904 and four positioning pins 1905, four shaft holes 1906 are evenly arranged on the described threshing device housing 1901, and each shaft hole 1906 is inserted into a shaft hole 1906. The cutter head installation shaft 1902 that slides inside, and one end of each cutter head installation shaft 1902 is fixed with the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com