Tobacco stem-leaf separating and re-curing process

A technology of threshing, redrying and stalking, which is applied in the directions of tobacco, tobacco preparation, tobacco treatment, etc., can solve the problem that the physical properties of tobacco stems and leaves cannot be well taken into account, the horizontal threshing unit has a large load, and the utilization of tobacco stems is unfavorable. and other problems, to achieve the effect of small footprint, increase production capacity, and reduce the number of threshing and wind grading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

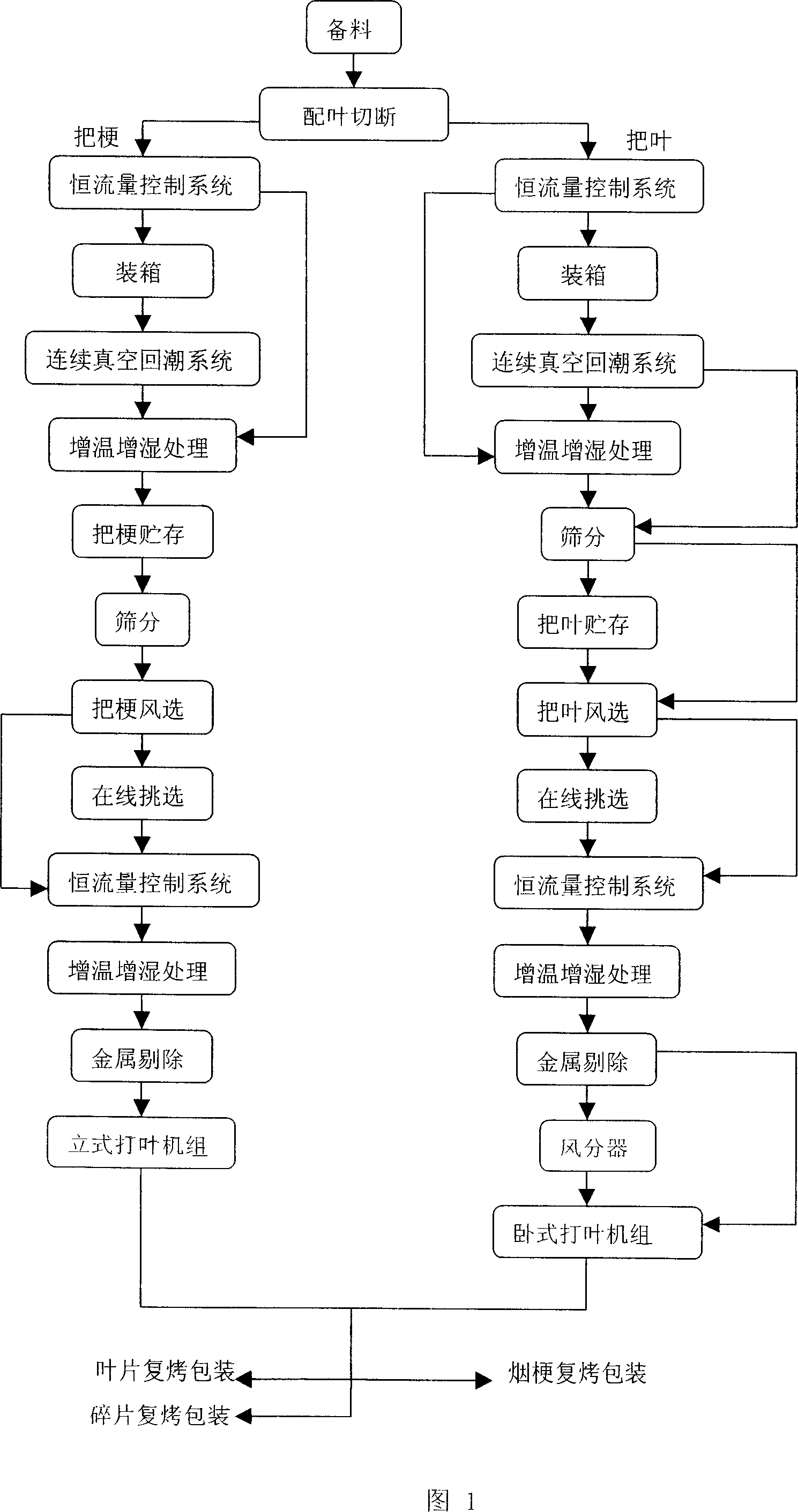

[0024] As shown in the figure, the technological process of the present invention is as follows:

[0025] ①Put the tobacco leaves one by one on the leaf cutting table, and cut and separate the stems mainly composed of tobacco stems from the leaves mainly composed of leaves;

[0026] ②The stem material will be processed according to the following process route:

[0027] a) Send the stalks into the constant flow control system composed of feeder and electronic scale to control the stable material flow;

[0028] b) Pack the stem material into a continuous vacuum dampening system for vacuum dampening treatment, and then send it to a drum type leaf conditioner for warming and humidifying treatment. The warming and humidifying treatment can be carried out several times according to the condition of the tobacco stems, and then carry out Storage, so that the tobacco stems can fully absorb water and improve the toughness and processing resistance of the material;

[0029] c) Use a vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com