Threshing machine

A threshing machine and frame technology, applied in agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems of high labor intensity, inability to use large-scale harvesting equipment, low efficiency of manual harvesting and threshing, and achieve high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

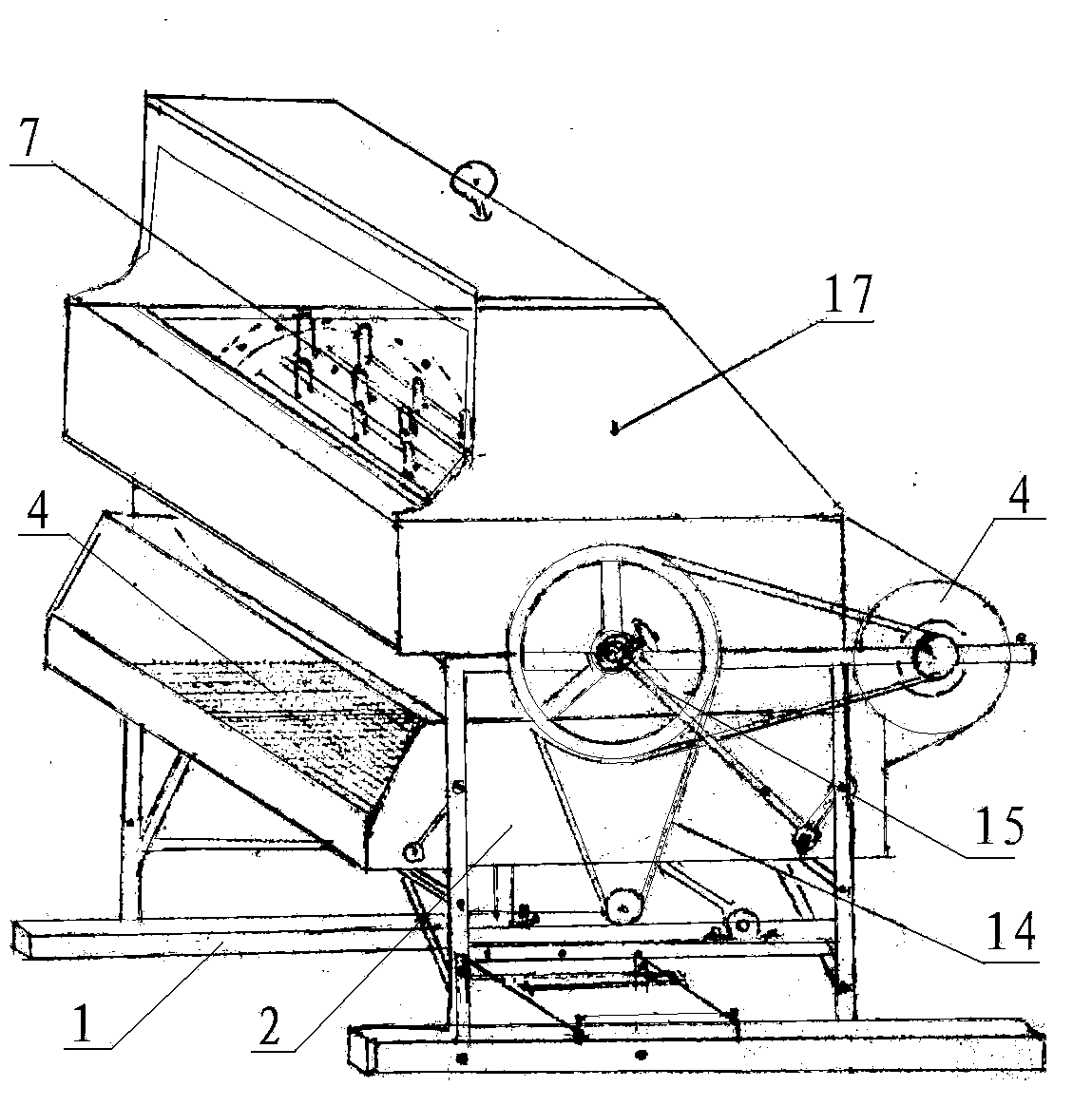

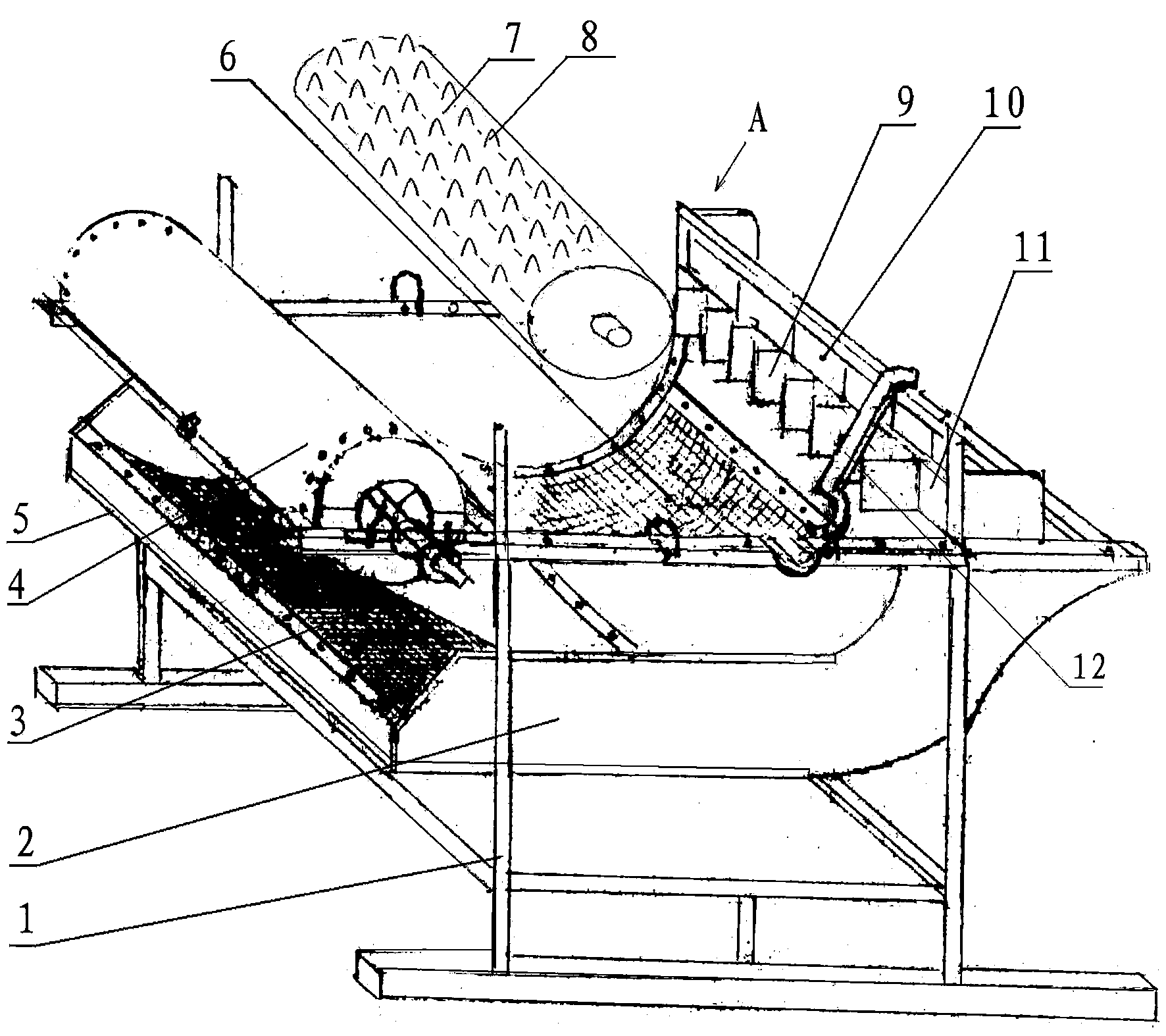

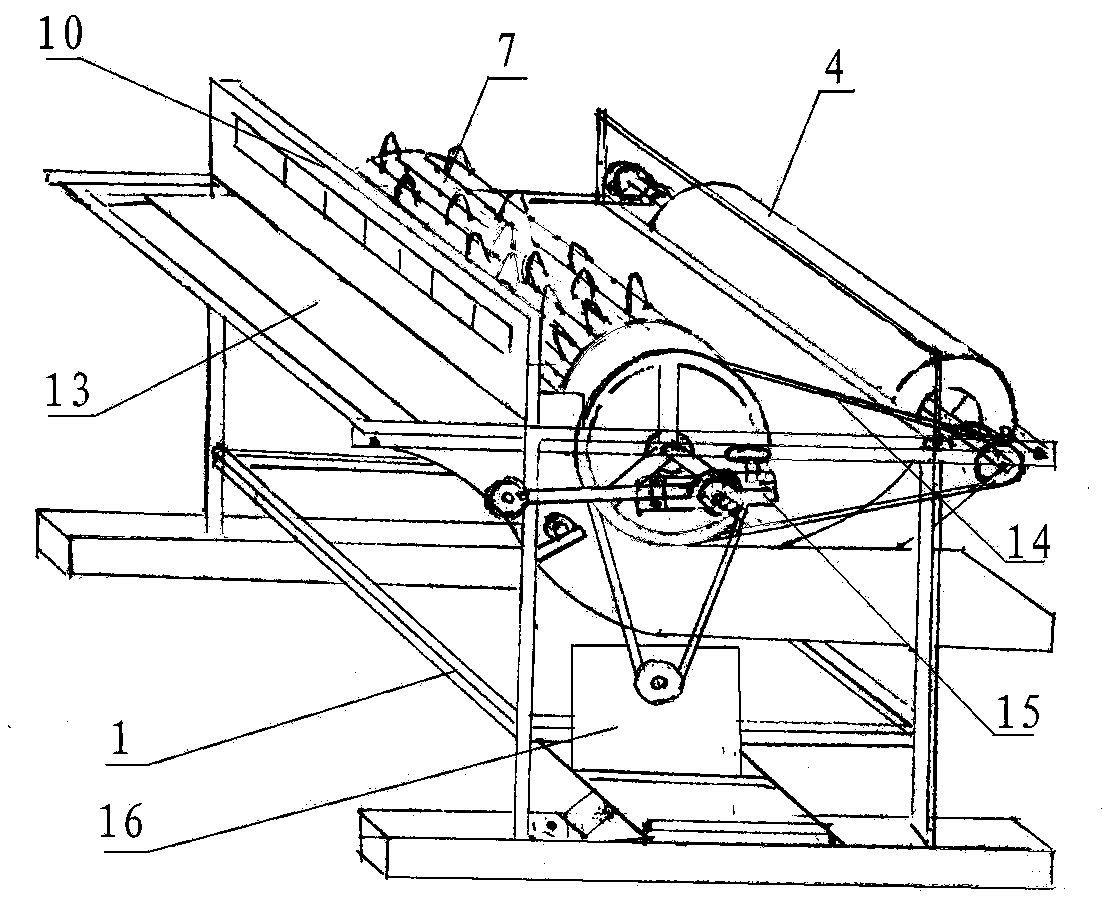

[0014] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0015] Such as Figure 1 to Figure 4 Shown this threshing machine, it comprises frame 1, and frame 1 both sides and rear side are respectively provided with side plate 2 and rear plate 13, and frame 1 top is provided with cover body 17, and cover body 17 is arranged on frame 1. There is a gauze on one side of the rear, which can observe the threshing situation and prevent impurities from splashing out; there is a hook on the top of the cover body 17, which is convenient for loading and unloading; the cover body 17 is opened in front of the frame 1, so that the harvested mature rice can be placed .

[0016] The frame 1 is provided with a knife rest 11 on the back plate 13 tops, and the knife rest 11 is evenly provided with a plurality of cutting knives 9 with cutting edges forward. There are threshing rollers 7 installed on the side plates 2 on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com