Cole gathering and threshing mill

A thresher and pick-up mechanism technology, which is applied to threshing equipment, loaders, agricultural machinery and implements, etc., can solve the problems of fresh rapeseed that cannot be threshed, and achieve the effect of improving operation efficiency and ensuring harvest quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

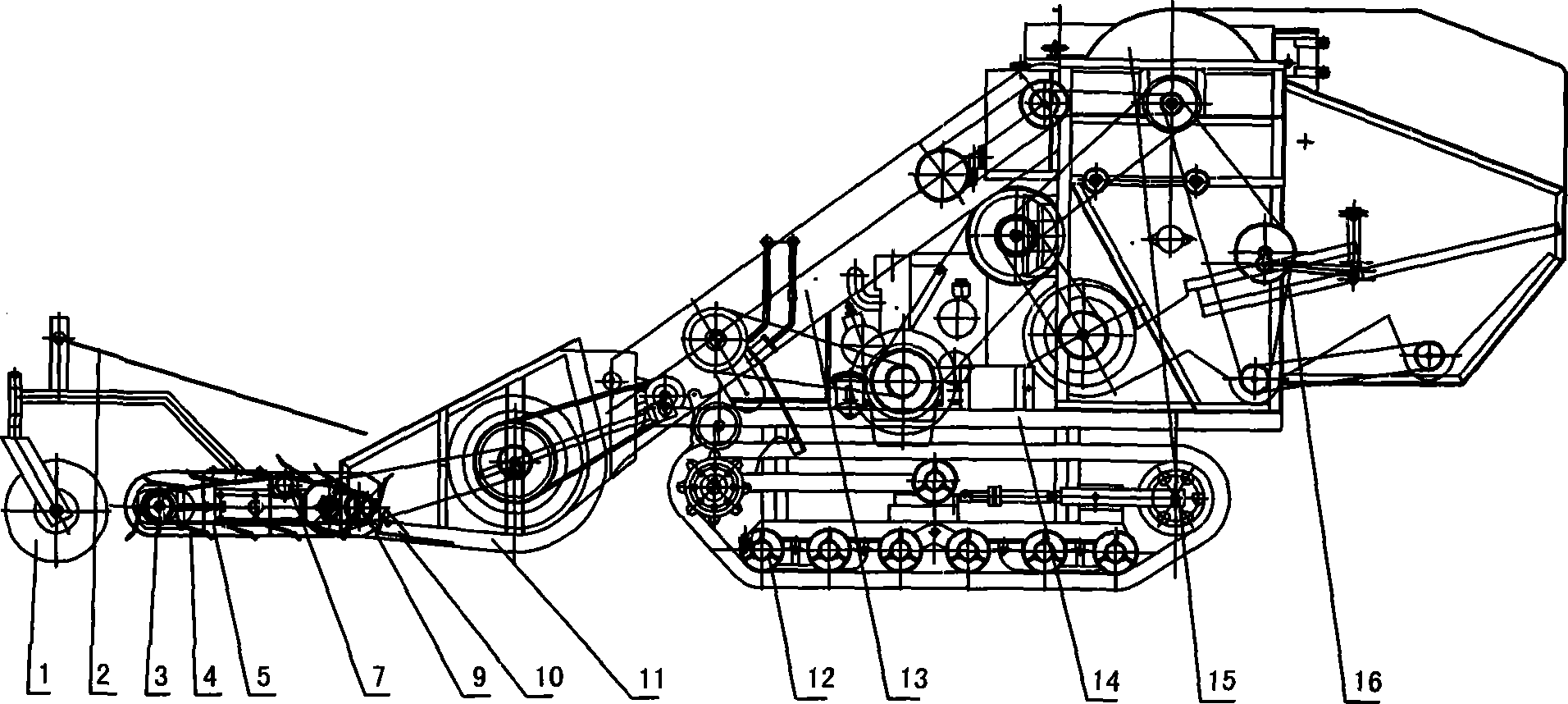

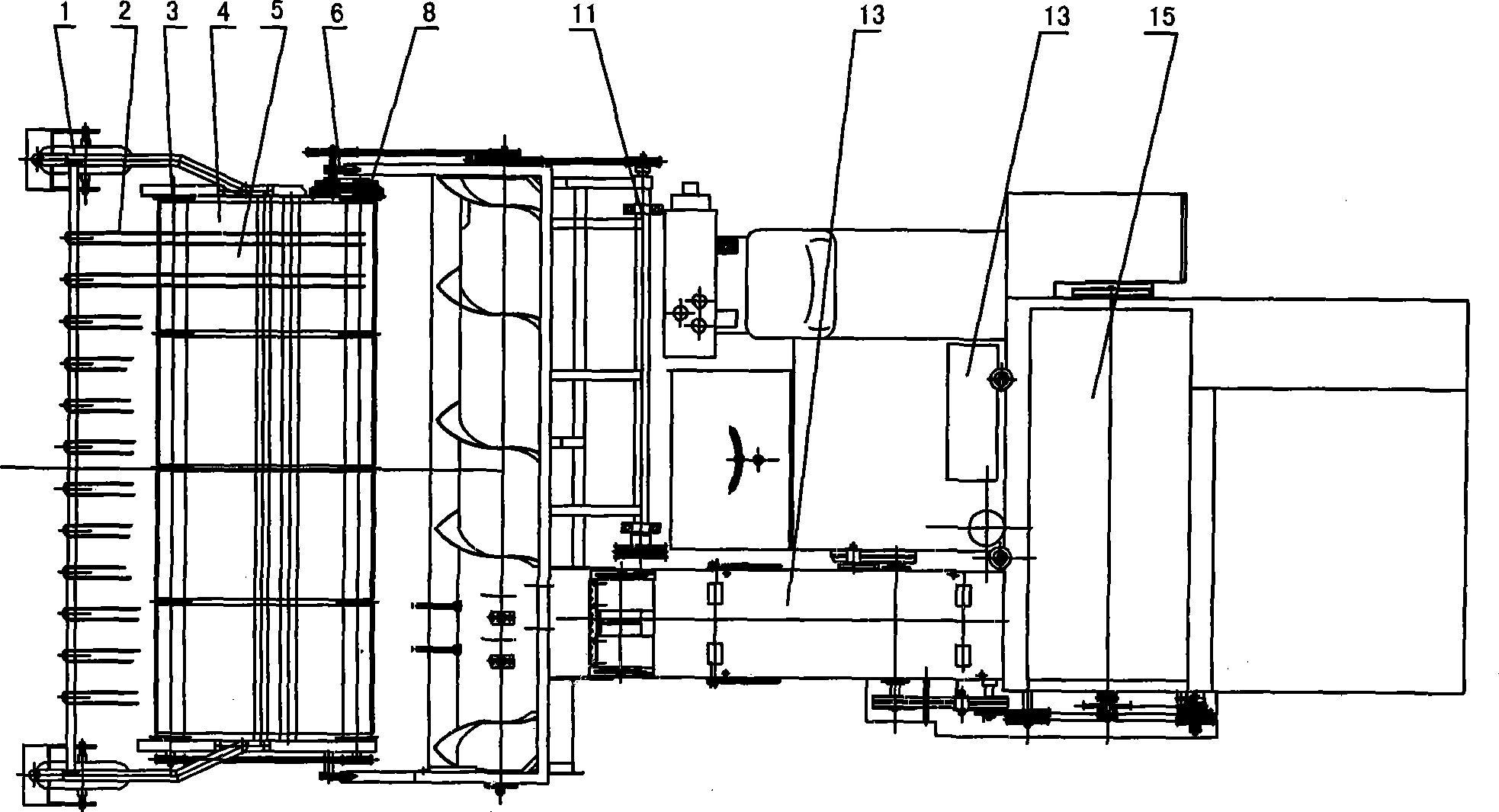

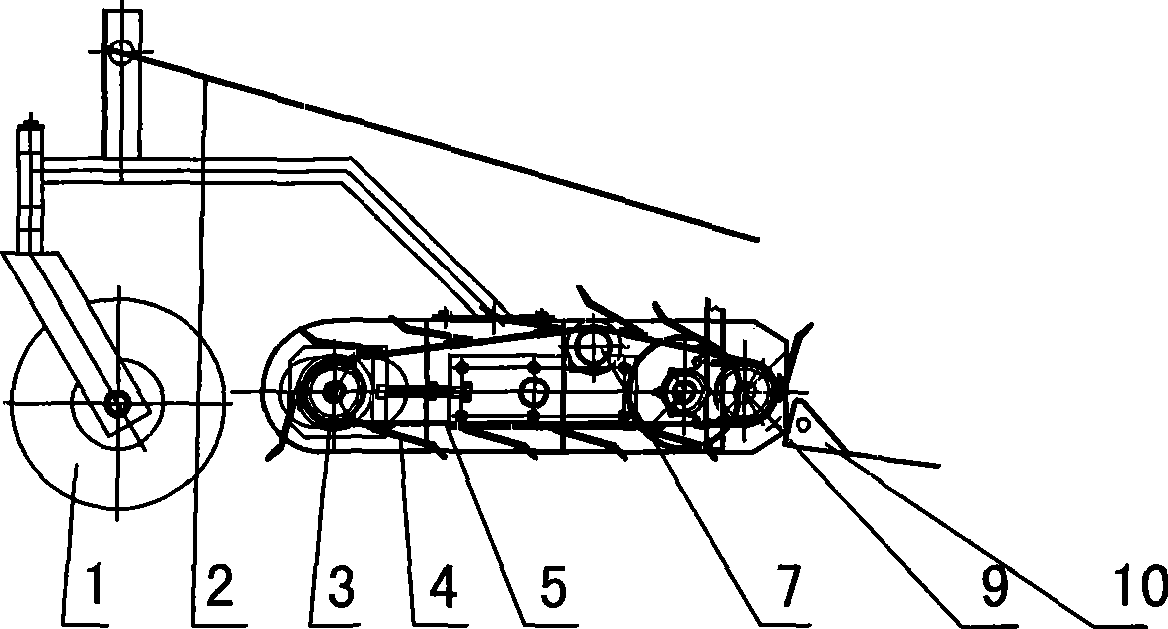

[0016] This embodiment is named rubber crawler self-propelled rape picking thresher device, the main components are as follows figure 1 , figure 2 , image 3 As shown, it includes profiling ground wheel 1, limit steel bar 2, driven roller shaft 3, nylon elastic conveying gear 4, toothed belt 5, hook device 6, middle roller shaft 7, power transmission reversing mechanism 8, Driving roller shaft 9, feeding guide plate 10, header feeding device 11, traveling chassis 12, conveying device 13, frame 14, threshing device 15, separation and cleaning mechanism 16 and other parts.

[0017] The traction-driven thresher part directly adopts the existing rubber crawler self-propelled rice and wheat combine harvester. The combine harvester has a header feeding device 11, a walking chassis 12, a conveying device 13, a frame 14, a threshing device 15, a separation and cleaning mechanism 16, and the like. The header feeding device 11 is located at the front. Bearing blocks are installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com