Automatic green Chinese onion collecting and laying mechanism of green Chinese onion harvester

A harvester and automatic technology, applied in the field of agricultural and forestry machinery, can solve the problems of poor harvest continuity, high labor intensity, low collection efficiency, etc., and achieve the effect of avoiding bending deformation and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

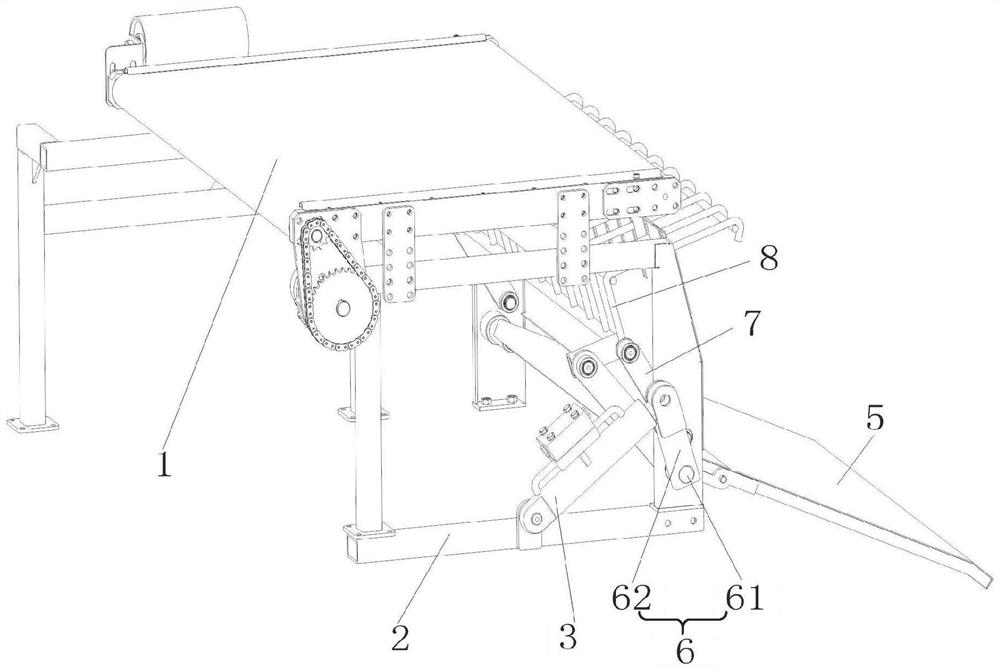

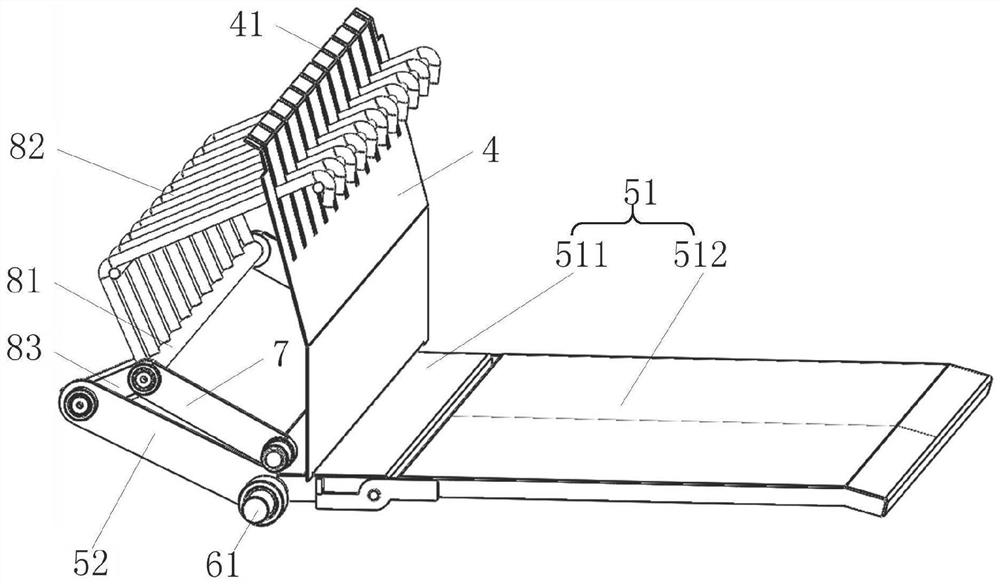

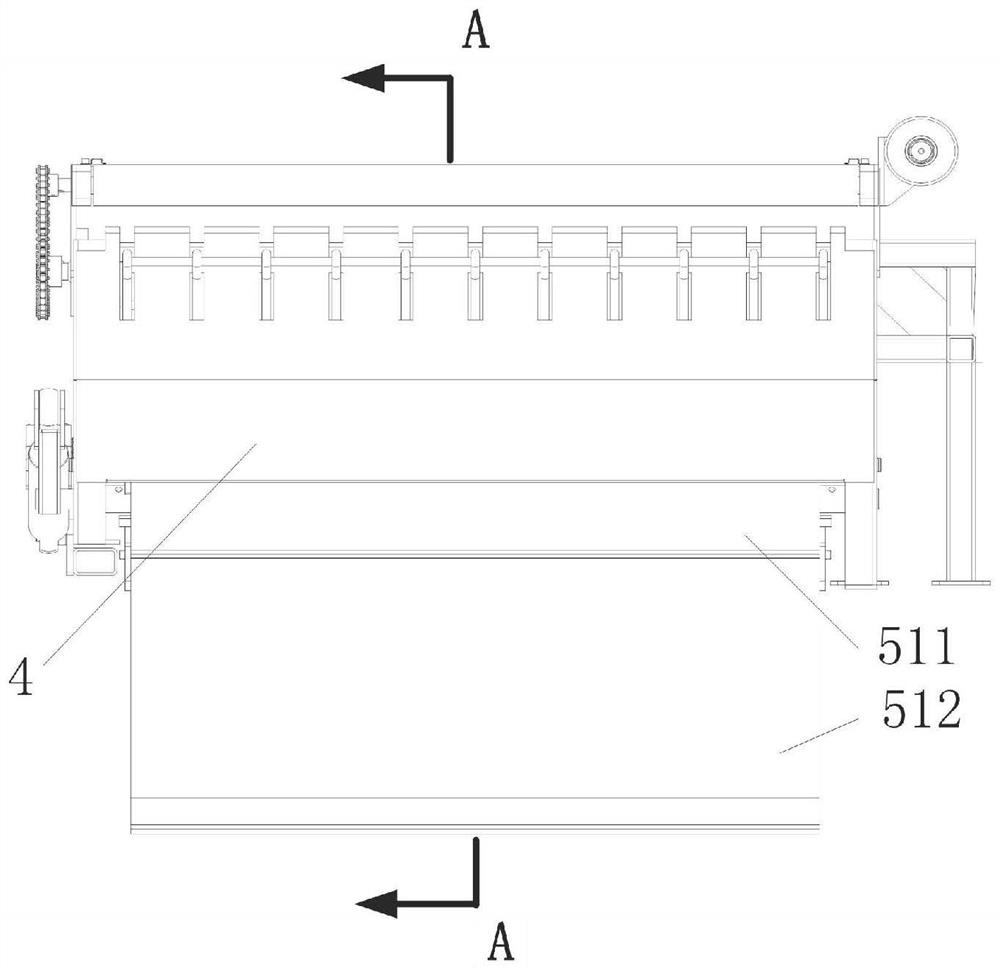

[0049] Such as figure 1 and as figure 2 As shown, a green onion harvester automatic collection and laying mechanism includes: support frame 2, conveyor belt assembly 1, hydraulic cylinder 3, baffle plate 4, tray shaft assembly 6, tray assembly 5, two driven Rocking bar 7 and comb frame 8,

[0050] The conveyor belt assembly 1 is installed on the top of the support frame 2; the hydraulic cylinder 3 is hinged at the bottom of the support frame 2; the baffle plate 4 is located below the output end of the conveyor belt assembly 1 in the conveying direction and fixed on the support frame 2, and its top edge corresponds to the output The end is provided with a plurality of long slotted holes 41 consistent with the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com