Flexible differential corn threshing machine

A technology of thresher and differential speed, which is applied in threshing equipment, agricultural machinery and implements, applications, etc. It can solve the problems of difficult to keep corn cobs intact, high corn seed damage rate, and incomplete threshing, so as to reduce the damage rate and threshing The effect of improving efficiency and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

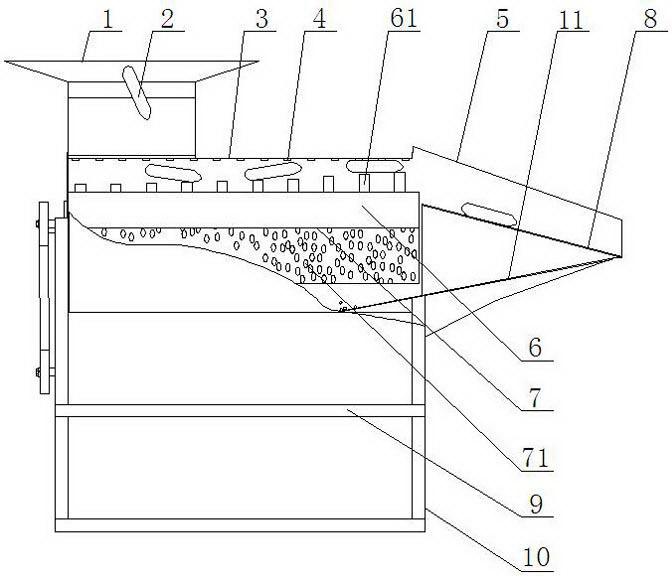

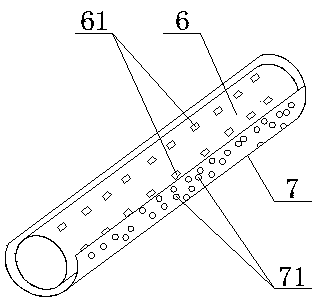

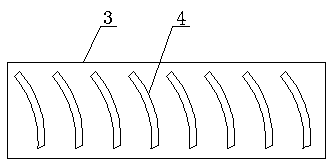

[0017] Such as figure 1 As shown, a flexible differential corn thresher includes a frame 10 placed on the ground, a threshing chamber 3 fixed on the frame 10, a feeding hopper 1 arranged at the upper part of the input end of the threshing chamber 3, and a threshing chamber 3 The end of the output end and is used to discharge the core bucket 5 of the corn cob, and the sieve plate 8 arranged inside the core bucket 5 for separating the corn kernels and the corn cob. The threshing chamber 3 is provided with a threshing machine driven by a motor to rotate Cylinder 6 and the annular concave plate 7 that is located at the periphery of threshing cylinder 6, the two ends of annular concave plate 7 are fixed on the threshing chamber 3, as figure 2 As shown, the annular concave plate 7 is wrapped around the periphery of the threshing cylinder 6 at 270°, and there is a certain gap between the threshing cylinder 6 and the annular concave plate 7. To separate the corn kernels from the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com